This section offers a detailed exploration of the techniques and considerations essential for maintaining and restoring a particular power unit. The objective is to empower enthusiasts and technicians alike with the knowledge necessary to tackle various challenges that may arise during the maintenance process.

Through a methodical approach, readers will discover insights into the internal workings of this mechanical marvel. From understanding its components to troubleshooting common issues, this guide serves as a valuable resource for those eager to enhance their expertise and ensure optimal performance.

Whether you are a seasoned professional or an avid hobbyist, this comprehensive overview provides practical tips and strategies aimed at simplifying the complexities often associated with overhauling such machinery. Embrace the journey of discovery and mastery in this fascinating realm.

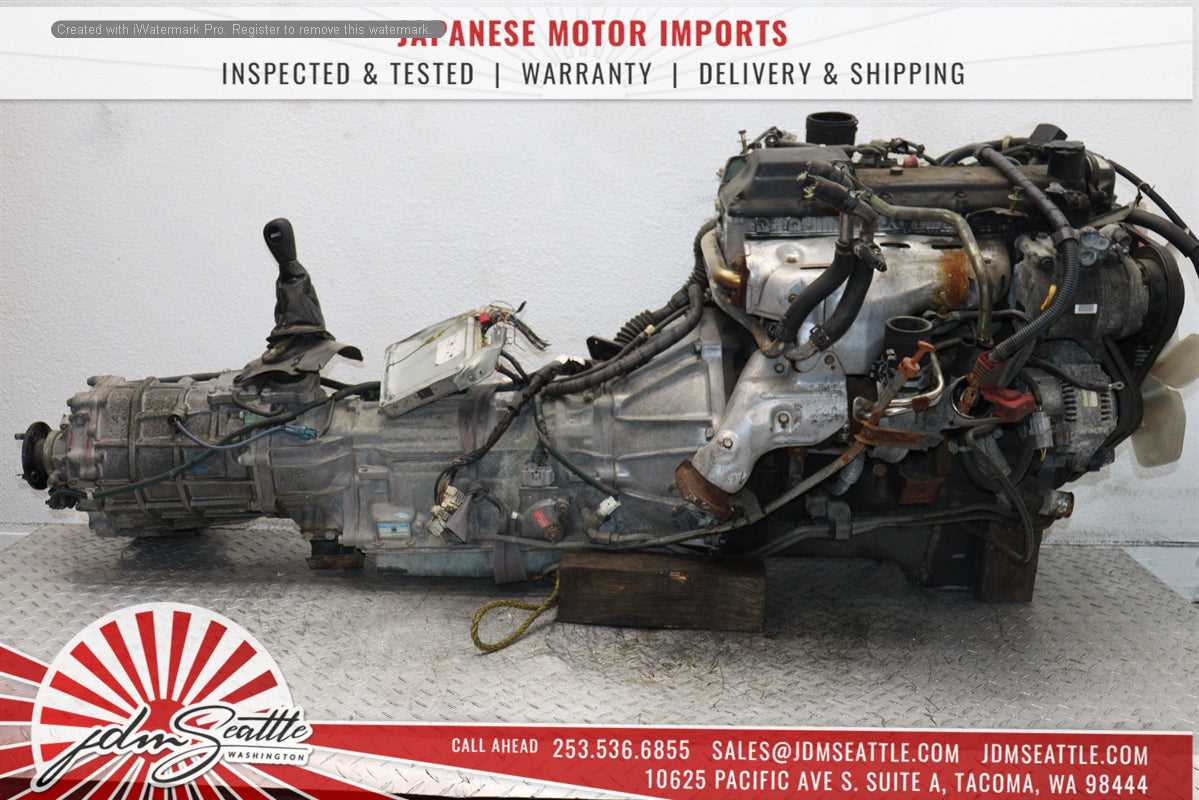

This section aims to provide a comprehensive overview of a specific internal combustion unit, highlighting its fundamental characteristics, operational principles, and the significance of routine maintenance for optimal performance. Understanding the intricacies of this power source is essential for anyone involved in its upkeep or enhancement.

Key Features and Specifications

Delving into the distinctive attributes of the unit, we explore its design elements, power output, and efficiency metrics. These factors are pivotal in determining its suitability for various applications and driving conditions.

| Feature | Details |

|---|---|

| Cylinder Configuration | In-line 4-cylinder |

| Displacement | 3.0 liters |

| Fuel Type | Diesel |

| Max Power | 130 HP |

| Torque | 300 Nm |

Importance of Maintenance

Regular servicing is crucial for maintaining the longevity and reliability of this power unit. Addressing wear and tear, fluid changes, and component inspections ensure optimal functionality and prevent unexpected failures.

Common Issues and Symptoms

When dealing with automotive powertrains, certain complications may arise that indicate underlying problems. Recognizing these signs is essential for timely intervention and maintaining optimal performance.

- Overheating: Excessive heat can lead to significant damage. Monitor the temperature gauge and check for coolant leaks.

- Excessive smoke: Smoke emanating from the exhaust can signal issues with combustion or lubrication.

- Unusual noises: Grinding, knocking, or tapping sounds may suggest mechanical wear or failure.

- Decreased power: A noticeable drop in acceleration or overall performance can indicate various issues, including fuel delivery problems.

- Rough idle: Irregular engine vibrations when stationary can point to problems with air-fuel mixture or ignition components.

Addressing these issues promptly can prevent more severe damage and ensure longevity. Regular maintenance checks and attentive observation are key to identifying these early warning signs.

Essential Tools for Repair

Having the right equipment is crucial for successful maintenance tasks. A well-equipped workspace ensures that the job can be completed efficiently and effectively. Below are some fundamental instruments that are essential for any thorough service project.

Basic Hand Tools

Hand tools are the foundation of any workshop. These items allow for precise adjustments and general assembly. Here is a list of basic tools that every technician should have:

| Tool | Purpose |

|---|---|

| Wrenches | Used for tightening or loosening bolts and nuts. |

| Screwdrivers | Essential for driving screws in various sizes and types. |

| Pliers | Useful for gripping, twisting, and cutting wires. |

Diagnostic Equipment

Accurate assessment is vital for any maintenance process. Diagnostic tools help identify issues before they become significant problems. Consider adding the following devices to your toolkit:

| Device | Function |

|---|---|

| Multimeter | Measures voltage, current, and resistance to troubleshoot electrical components. |

| OBD-II Scanner | Reads and clears trouble codes from the control unit for fault detection. |

Step-by-Step Maintenance Procedures

Proper upkeep of your vehicle’s power unit is essential for optimal performance and longevity. This section outlines systematic processes that will help ensure everything operates smoothly. Following these procedures will not only enhance functionality but also prevent future issues.

Regular Inspection and Cleaning

Begin with routine examinations of critical components. Checking for signs of wear or damage can prevent unexpected failures. Clean various parts thoroughly to eliminate dirt and debris, which can hinder performance. Use appropriate tools and cleaners to ensure all surfaces are adequately maintained.

Fluid Checks and Replacements

Monitoring and replacing essential fluids is crucial for the system’s efficiency. Check levels of lubricants, coolants, and other necessary fluids, topping them off or changing them as needed. Ensure that you use the recommended types to maintain compatibility and performance.

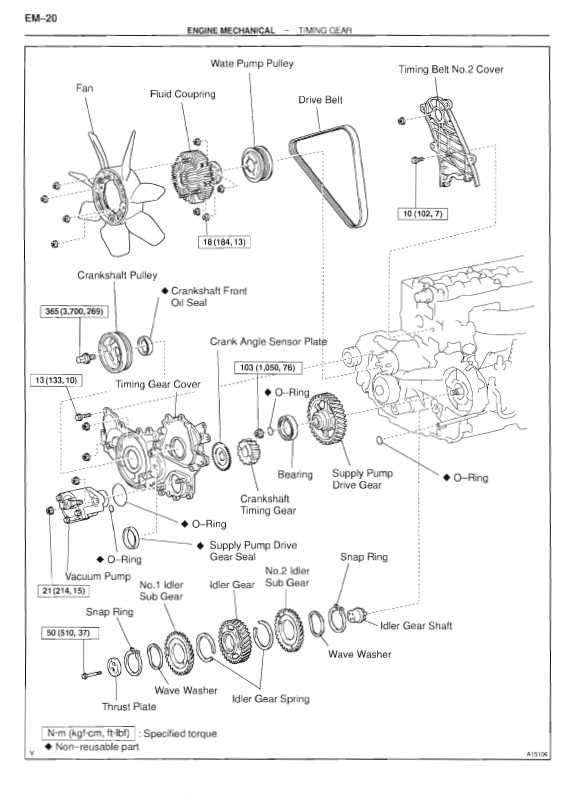

Disassembly and Reassembly Guidelines

This section provides essential procedures for taking apart and putting back together complex mechanical systems. Following these guidelines ensures that all components are handled properly, minimizing the risk of damage during the process. Understanding the sequence of disassembly and reassembly is crucial for maintaining functionality and performance.

Begin by organizing tools and components, labeling parts as they are removed to facilitate easier reassembly. Carefully follow the recommended steps, paying attention to any specific instructions related to the sequence and technique. It’s important to work in a clean environment to prevent contamination and to avoid losing small components.

When reassembling, ensure all seals and gaskets are in good condition and properly positioned. Torque specifications should be adhered to, as incorrect fastening can lead to malfunctions. Finally, conduct a thorough inspection before testing the system to ensure everything is functioning as intended.

Diagnosing Electrical Problems

Identifying issues within the electrical system of a vehicle is crucial for ensuring optimal performance. Many complications stem from faulty wiring, poor connections, or malfunctioning components. By systematically evaluating the system, one can pinpoint the source of the problem and implement effective solutions.

Begin the diagnosis by gathering essential tools, such as a multimeter, and familiarize yourself with the circuitry. Checking for voltage irregularities, inspecting connectors, and verifying the integrity of wires can reveal underlying issues. Below is a table summarizing common electrical problems and their potential causes:

| Problem | Possible Cause |

|---|---|

| Dim lights | Weak battery or poor ground connection |

| Unresponsive starter | Faulty starter motor or ignition switch |

| Malfunctioning accessories | Blown fuse or bad wiring |

| Battery drain | Parasitic draw from components |

By utilizing a methodical approach and consulting the table above, one can effectively address electrical faults and restore functionality to the system.

Upgrading Components for Performance

Enhancing the functionality of your vehicle involves optimizing various elements to achieve superior performance. This process not only boosts power output but also improves efficiency and driving dynamics. A thoughtful approach to component upgrades can significantly transform the overall experience.

Evaluating Key Parts

Before embarking on any enhancement journey, it is crucial to assess which components will yield the most benefits. Prioritizing parts such as the intake system, exhaust layout, and fuel delivery mechanisms can lead to notable improvements. Upgrading these sections can facilitate better airflow and combustion, ultimately enhancing horsepower and torque.

Choosing Quality Upgrades

When selecting replacements, focus on high-quality alternatives that are known for their reliability and performance. Aftermarket options often provide significant advancements over factory settings. Investing in reputable brands ensures that the enhancements contribute positively to your vehicle’s longevity and capabilities.

Safety Precautions During Repair

Ensuring safety is paramount when undertaking any maintenance or servicing tasks. Adhering to specific guidelines can significantly reduce the risk of accidents and injuries. Proper preparation and awareness of potential hazards are essential for a successful and secure work environment.

Personal Protective Equipment

Utilizing appropriate personal protective equipment (PPE) is crucial. This includes safety glasses to shield the eyes from debris, gloves to protect the hands from chemicals and sharp objects, and sturdy footwear to prevent slips and provide ankle support. Wearing a mask may also be advisable when working with dust or fumes.

Work Area Organization

Keeping the workspace tidy and organized helps minimize hazards. Ensure all tools and materials are easily accessible and securely stored. Adequate lighting is also essential to avoid accidents caused by poor visibility. Regularly check for any spills or obstructions that could lead to slips or falls.

Finding Quality Replacement Parts

When it comes to maintaining your vehicle, sourcing high-quality components is essential for ensuring longevity and performance. Selecting the right pieces can significantly impact functionality and reliability.

Here are some key considerations when looking for suitable replacements:

- Research Brands: Investigate various manufacturers known for their durable and efficient parts.

- Check Reviews: Look for feedback from other users to gauge the reliability and performance of specific components.

- Compare Prices: Shop around to find competitive pricing, but beware of extremely low-cost options that may compromise quality.

- Verify Compatibility: Ensure that the parts you are considering are compatible with your specific vehicle model.

Additionally, purchasing from reputable retailers, both online and in-store, can provide added assurance of quality. Opting for warranty-backed products may also offer peace of mind, as they reflect the manufacturer’s confidence in their durability.

Resources for Troubleshooting Assistance

When faced with mechanical challenges, having access to reliable sources can significantly enhance the troubleshooting process. These resources provide invaluable guidance, offering insights into common issues and effective solutions. Whether you are a novice or an experienced individual, leveraging these tools can lead to successful resolutions.

Here are some recommended platforms and materials to consider:

| Resource Type | Description | Access Method |

|---|---|---|

| Online Forums | Communities where enthusiasts share experiences and solutions. | Visit specialized automotive discussion boards. |

| Technical Publications | Detailed documents covering various aspects of maintenance. | Obtain from automotive bookstores or libraries. |

| Video Tutorials | Visual guides demonstrating troubleshooting techniques. | Available on platforms like YouTube. |

| Diagnostic Tools | Equipment for identifying and resolving issues. | Purchase from automotive supply stores. |