When it comes to preserving the functionality and performance of a vehicle’s transmission, understanding the intricacies of its structure is essential. This section delves into the critical aspects of caring for one of the well-regarded automatic transmission models, known for its reliability and advanced engineering. Here, you’ll find insights into routine upkeep practices and diagnostic tips that are aimed at extending the transmission’s lifespan.

Basic Care Principles are a significant focus, emphasizing preventive measures to ensure that each component functions optimally. From fluid checks to component inspections, these practices are fundamental to maintaining the stability and smooth operation of your transmission over time. Addressing potential issues early helps to avoid extensive work, ensuring smoother and longer-lasting performance.

Additionally, this guide explores common technical issues that may arise, offering step-by-step suggestions to navigate and resolve them effectively. Whether it’s troubleshooting specific components or understanding which tools to use, this resource provides clear instructions designed to support enthusiasts and professionals alike in keeping their transmission in prime condition.

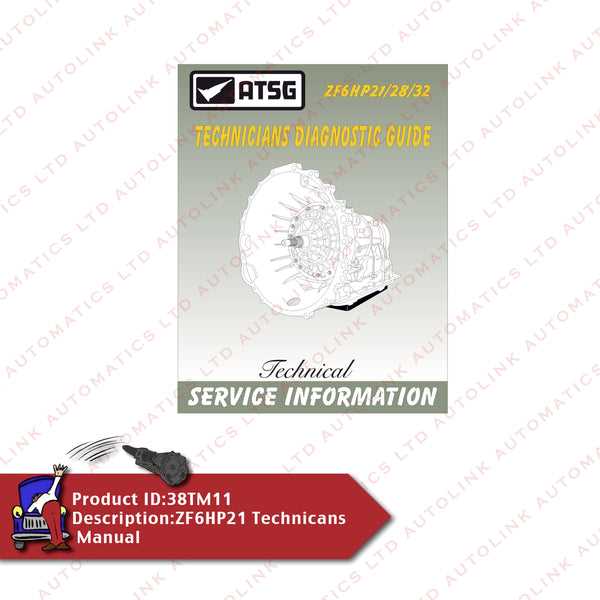

Zf 6hp21 Repair Manual

The following section provides a comprehensive overview of the procedures and techniques required for effective upkeep and troubleshooting of this advanced transmission system. Known for its durability and intricate design, this unit requires precise handling and specialized knowledge for successful maintenance and adjustments.

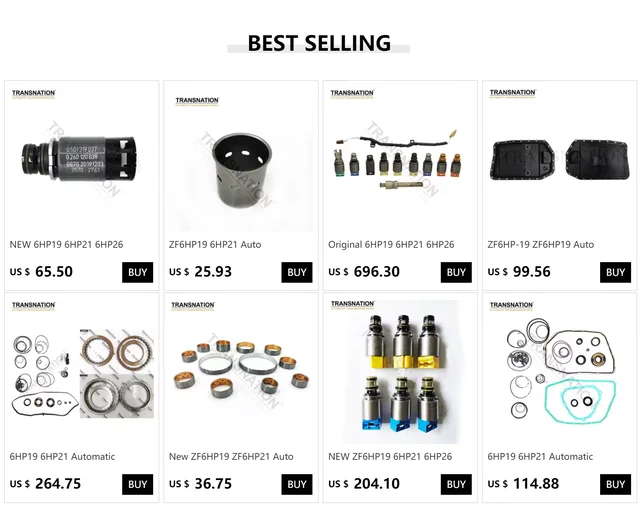

Key components within this transmission demand attention to specific details, from gear assembly to electronic controls. The table below outlines the primary elements requiring regular inspection and typical tasks to maintain optimal function and longevity of the system.

| Component | Maintenance Task | Frequency |

|---|---|---|

| Torque Converter | Inspect for wear, replace fluid | Every 30,000 miles |

| Valve Body | Check solenoid operation, clean channels | Annually |

| Clutch Pack | Assess for signs of slipping or degradation | Biannually |

| Electronic Control Module | Scan for error codes, update software | Every service interval |

Common Issues and Solutions

Automatic transmissions are complex systems with numerous components that must work in unison for smooth vehicle performance. Over time, wear and tear or unexpected mechanical issues may arise, impacting functionality. By recognizing frequent complications and understanding effective ways to address them, drivers can maintain optimal transmission health and avoid costly overhauls.

One common issue includes delayed shifting between gears, often noticeable during acceleration or deceleration. This delay can stem from fluid-related issues, such as insufficient fluid levels or contamination, which can be resolved by replacing the transmission fluid and filter at regular intervals.

Another typical concern is unusual noises during gear changes, often caused by worn internal parts or inadequate lubrication. Routine inspection of gears and bearings can help identify these early warning signs, allowing for timely replacement of any degraded components.

Furthermore, overheating is a frequent problem that can lead to reduced performance and, eventually, severe damage. Installing an additional cooling system or ensuring the transmission’s cooling lines are clear can aid in maintaining a stable operating temperature.

Finally, slipping gears, where the vehicle unexpectedly shifts out of gear, is often due to worn clutches or bands within the system. Regularly inspecting and servicing these parts can help prevent slipping and ensure smooth transitions between gears.

Disassembly Process for Beginners

Disassembling a transmission can be a challenging task, but with the right approach, it becomes manageable even for those new to the process. In this guide, we’ll explore fundamental steps to safely open and examine key parts. Understanding the arrangement of internal components and following a systematic method can help avoid common mistakes.

Initial Preparation

Before starting, gather all necessary tools, such as socket wrenches, screwdrivers, and containers for smaller parts. Prepare a clean and organized workspace to prevent misplacing items and label all components as you remove them. Careful preparation sets the foundation for efficient reassembly later on.

Main Steps of Disassembly

Begin by carefully disconnecting external connections and loosening bolts that secure the transmission casing. As you work, use gentle force and avoid abrupt movements to prevent damaging sensitive parts. Once opened, examine each section sequentially and document the layout to facilitate the process when putting everything back together. Keeping a structured approach ensures a smoother experience for any beginner tackling this task.

Tools Needed for Proper Repair

When working on a complex mechanism, it’s crucial to have the correct set of instruments to ensure accurate adjustments and maintenance. Each tool plays a specific role, making it easier to address various components effectively and to avoid further issues.

Basic Hand Tools are essential for initial tasks and disassembly. These include high-quality screwdrivers, socket wrenches, and pliers. Precision and durability are key when selecting these tools, as they will be used frequently for tightening, loosening, and handling smaller parts.

Specialized Equipment is needed for more intricate tasks. A sturdy torque wrench helps apply the correct force to bolts, preventing damage or loose fittings. Additionally, alignment tools assist in ensuring all parts are properly positioned, reducing wear and tear during operation.

Diagnostics Tools such as a reliable scan tool or code reader are invaluable for assessing the system’s status. These tools can identify any underlying issues that may not be visible initially, allowing for a thorough and precise service.

Investing in the right set of quality tools can significantly enhance the effectiveness of any task and help extend the longevity of the machinery. Proper equipment enables safer and more accurate work, ensuring optimal functionality in the long term.

Inspecting the Transmission Components

Effective maintenance of the transmission involves a comprehensive examination of each part to ensure reliable operation. By identifying wear or potential issues early, you can prevent costly disruptions and enhance the overall performance of the vehicle’s drivetrain system.

Initial Visual Assessment: Begin by visually examining the external and internal elements of the transmission. Look for signs of leakage, discoloration, or unusual deposits, as these may indicate contamination or component deterioration. Pay special attention to connectors and seals, as these are common sources of leakage and damage.

Checking Gears and Clutches: Inspect all gear and clutch assemblies for wear, scoring, or chipped teeth. These issues can lead to slipping or shifting delays, which impact the smoothness of gear transitions. Clutch plates should show even wear; uneven patterns often suggest incorrect alignment or improper lubrication.

Assessing Valves and Solenoids: Valves and solenoids play a crucial role in managing fluid pressure within the transmission. Inspect each component for proper movement and responsiveness. If a valve or solenoid is stuck, worn, or clogged, it can disrupt fluid flow, leading to sluggish performance or overheating.

Evaluating Bearings and Seals: Bearings support the rotation and load distribution in the transmission system. Examine them for signs of scoring, wear, or play, as these can compromise stability and cause excessive noise. Seals

Reassembly Tips for Optimal Performance

Reassembling a complex mechanical unit requires attention to detail and a systematic approach to ensure functionality and efficiency. Following specific guidelines during this process can significantly enhance the performance and longevity of the assembly.

1. Clean All Components

Before beginning the reassembly, it is crucial to thoroughly clean all parts. Remove any dirt, debris, or old lubricant to prevent contamination during the assembly. Use a suitable solvent and a soft cloth to avoid scratching surfaces. This step ensures that all components fit together smoothly and operate without friction.

2. Follow the Sequence

Adhere to the original assembly sequence as closely as possible. This method helps to maintain the integrity of the unit and ensures that all components are aligned correctly. Utilize diagrams or notes from the disassembly process to guide you. Furthermore, taking the time to double-check the alignment can prevent potential issues during operation.

Proper lubrication is also essential. Apply the recommended lubricant to moving parts to reduce wear and improve efficiency. Pay attention to the quantity, as too much or too little can lead to malfunction.

Finally, test the assembly under controlled conditions before full operation. This practice allows you to identify and rectify any issues that may arise, ensuring optimal performance when in use.

Fluid Types and Replacement Guide

Maintaining the proper fluid levels and types is essential for the optimal performance of any automatic transmission. The choice of fluid can significantly influence the longevity and efficiency of the system, making it crucial to adhere to manufacturer specifications and guidelines. Regular monitoring and timely replacement of these fluids ensure smooth operation and prevent potential issues.

There are several fluid categories commonly used in automatic transmissions, each designed for specific applications and conditions. Understanding these types will help in selecting the right one for your system.

| Fluid Type | Description | Recommended Replacement Interval |

|---|---|---|

| ATF (Automatic Transmission Fluid) | A specially formulated oil for automatic transmissions that provides lubrication, cooling, and cleaning. | Every 30,000 to 60,000 miles |

| CVT Fluid | Fluid designed for continuously variable transmissions, offering excellent protection and performance. | Every 25,000 to 50,000 miles |

| Dual-Clutch Fluid | High-performance fluid for dual-clutch systems, engineered to handle the demands of rapid gear shifts. | Every 40,000 to 60,000 miles |

| Friction Modifier | Added to enhance the performance of certain types of transmissions by improving friction characteristics. | As needed, typically during maintenance |

Choosing the appropriate fluid type and adhering to replacement intervals is vital for maintaining the system’s integrity. Always consult the specific guidelines provided by the manufacturer for the best results.

Torque Specifications for Key Parts

This section provides essential details regarding the torque settings required for critical components in the transmission system. Proper torque application is vital for ensuring optimal performance and longevity of the assembly. Following the correct specifications minimizes the risk of failure and enhances reliability.

Below are the torque specifications for various key parts:

- Torque Converter Bolts:

- Initial Torque: 40 Nm

- Final Torque: 55 Nm

- Input Shaft Nuts:

- Initial Torque: 50 Nm

- Final Torque: 70 Nm

- Oil Pan Bolts:

- Initial Torque: 15 Nm

- Final Torque: 20 Nm

- Valve Body Fasteners:

- Initial Torque: 25 Nm

- Final Torque: 30 Nm

Adhering to these specifications is crucial for maintaining the integrity and functionality of the components involved. Always refer to the manufacturer’s guidelines for any updates or changes to these values.

Electrical System Diagnostics

The effectiveness of any automotive transmission relies heavily on its electrical components. Proper diagnostics of the electrical system is essential for ensuring optimal performance and longevity. This section focuses on identifying potential issues within the electrical framework that could impact the functionality of the transmission.

Begin the diagnostic process by examining the wiring harness for signs of wear, damage, or corrosion. A thorough inspection can reveal short circuits or poor connections that may lead to erratic behavior or complete failure of the system. Additionally, utilize a multimeter to check voltage levels at various connectors, ensuring they meet the specified standards for the transmission’s operation.

Another crucial aspect of diagnostics involves analyzing the control modules responsible for managing the transmission’s electrical functions. Regularly updating software and firmware can prevent compatibility issues and enhance the system’s responsiveness. Conducting a scan for fault codes using a suitable diagnostic tool will provide insights into any malfunctioning components and facilitate targeted troubleshooting.

In summary, maintaining a robust electrical system is vital for the reliable operation of the transmission. By implementing systematic diagnostic procedures, potential issues can be identified and rectified promptly, thus ensuring the longevity and efficiency of the transmission.

Preventative Maintenance Recommendations

Regular upkeep is essential for ensuring optimal performance and longevity of your transmission system. By implementing a consistent maintenance routine, potential issues can be identified early, minimizing the risk of major repairs and enhancing overall functionality.

Fluid Checks: Regularly inspect and replace transmission fluids as needed. Keeping fluids clean and at the correct levels is crucial for smooth operation and preventing overheating.

Filter Replacements: Change the transmission filter periodically to prevent contaminants from entering the system. A clean filter ensures that the fluid circulates freely and maintains optimal performance.

Visual Inspections: Conduct routine visual assessments of the transmission for signs of leaks, wear, or damage. Addressing these issues promptly can prevent more extensive damage down the line.

Drive Tests: Perform regular drive tests to monitor shifting quality and responsiveness. Unusual noises or changes in performance may indicate underlying issues that require attention.

Professional Servicing: Schedule professional maintenance at recommended intervals. Experienced technicians can provide thorough inspections and necessary adjustments, ensuring your system remains in peak condition.

Testing and Calibration after Repairs

Ensuring the optimal functionality of any complex system following maintenance is crucial. This process typically involves a series of assessments and adjustments to verify that the components operate within their specified parameters. Effective testing and calibration enhance reliability, improve performance, and extend the lifespan of the equipment.

Assessment Procedures

The assessment phase encompasses various techniques to evaluate system performance. These may include pressure tests, fluid flow measurements, and electronic diagnostics. Each method aims to identify any deviations from expected standards.

Calibration Techniques

Calibration is the process of aligning the system’s output with established benchmarks. This may involve adjusting settings based on feedback from measurement tools. Ensuring accuracy in calibration is essential for maintaining operational efficiency.

| Test Type | Description | Frequency |

|---|---|---|

| Pressure Test | Measures system pressure to ensure it meets specifications. | Every 500 miles |

| Fluid Analysis | Checks fluid quality and contaminants. | Every 3000 miles |

| Electronic Diagnostics | Utilizes software to scan for error codes and system performance. | Every service interval |