Maintaining outdoor machinery is crucial for ensuring its longevity and optimal performance. Whether you’re a seasoned professional or a hobbyist, understanding the fundamentals of upkeep can save time and resources. This guide aims to provide you with the necessary insights to troubleshoot and enhance the functionality of your equipment.

From basic adjustments to more intricate servicing tasks, comprehending the mechanics behind your machinery allows you to handle various challenges effectively. Regular maintenance not only helps in identifying potential issues early but also boosts efficiency, leading to a smoother operation. Empower yourself with knowledge and take charge of your equipment’s health.

With a focus on practical tips and techniques, this section will equip you with the skills needed to address common problems and perform routine checks. Dive into a comprehensive resource designed to support you in achieving a well-functioning machine, ready to tackle any outdoor task you encounter.

Understanding Your Craftsman Lawn Tractor

Gaining familiarity with your garden machine is essential for optimal performance and longevity. This section aims to enhance your knowledge about its components, functions, and maintenance needs. Recognizing how various parts work together will empower you to ensure efficiency and address potential issues promptly.

Every gardening device comprises several key elements that contribute to its operation. Below is a summary of these components:

| Component | Description |

|---|---|

| Engine | Powers the entire system, enabling movement and operation of attached tools. |

| Transmission | Transfers power from the engine to the wheels, allowing for various speeds. |

| Deck | Houses the cutting mechanism, determining the efficiency of trimming grass. |

| Wheels | Facilitate movement across different terrains, affecting stability and control. |

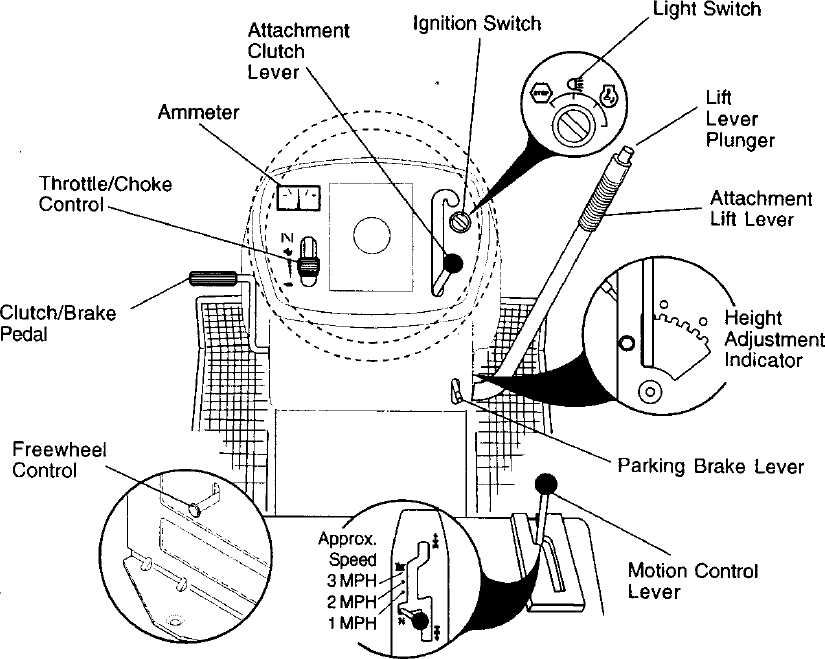

| Controls | Enable the operator to manage speed, direction, and cutting height with ease. |

Understanding these components will help you better manage your gardening tasks and extend the lifespan of your equipment. Regular upkeep and awareness of how each part functions are critical to avoiding common pitfalls and ensuring a seamless gardening experience.

Common Issues with Lawn Tractors

Maintaining outdoor equipment is essential for optimal performance and longevity. Many users encounter a variety of challenges that can hinder the effectiveness of their machines. Understanding these common problems can facilitate quicker troubleshooting and help ensure a smooth operation.

Engine Problems

- Starting Issues: Difficulty in ignition can stem from a weak battery, faulty spark plug, or fuel delivery problems.

- Overheating: Insufficient coolant, a clogged air filter, or debris in the cooling system can lead to excessive heat buildup.

- Unusual Noises: Strange sounds may indicate worn bearings, loose components, or issues with the exhaust system.

Cutting Performance

- Inefficient Cutting: Dull blades or improper height settings can result in uneven grass trimming.

- Clumping: Grass clippings may accumulate due to wet conditions or a blocked discharge chute.

- Vibration: Excessive shaking during operation can signal unbalanced blades or loose mounting hardware.

Essential Tools for Repairs

Having the right equipment is crucial for effective maintenance and troubleshooting of outdoor machinery. A well-equipped workshop not only enhances efficiency but also ensures safety while handling various tasks. Here are some vital instruments that every enthusiast should consider having on hand.

Basic Hand Tools

- Wrenches: Adjustable and fixed sizes are essential for loosening and tightening fasteners.

- Screwdrivers: A set including flathead and Phillips types will cover most needs.

- Pliers: Needle-nose and regular pliers help with gripping and bending tasks.

- Socket Set: Useful for accessing hard-to-reach bolts and nuts.

Specialized Instruments

- Multimeter: Essential for diagnosing electrical issues by measuring voltage, current, and resistance.

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications.

- Feeler Gauge: Useful for measuring gap widths in various components.

- Fuel System Cleaner: Helps maintain fuel lines and carburetors, ensuring optimal performance.

Equipping your workspace with these tools will prepare you for most challenges, allowing for efficient upkeep and enhancing the longevity of your equipment.

Step-by-Step Maintenance Guide

Proper upkeep of your outdoor machinery is essential for ensuring optimal performance and longevity. This section outlines a comprehensive approach to maintaining your equipment, highlighting critical tasks that should be performed regularly to avoid costly issues and enhance efficiency.

Essential Maintenance Tasks

To keep your machinery in top shape, consider the following fundamental tasks that should be part of your routine maintenance schedule:

| Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 50 hours | Replace the oil to prevent engine wear and ensure smooth operation. |

| Air Filter Cleaning | Every 25 hours | Clean or replace the air filter to maintain airflow and engine efficiency. |

| Blade Sharpening | At least once per season | Sharpen blades to ensure a clean cut and reduce stress on the engine. |

| Tire Inspection | Monthly | Check tire pressure and tread for safety and performance. |

| Belt Check | Every 100 hours | Inspect belts for wear and adjust or replace as necessary. |

Final Tips for Effective Care

In addition to the tasks mentioned, always refer to the specific guidelines provided by the manufacturer for tailored maintenance advice. Keeping a detailed log of completed tasks can help track your efforts and ensure nothing is overlooked. Regular attention will greatly extend the lifespan of your machinery and enhance its performance.

Engine Troubleshooting Techniques

Effective diagnosis of power unit issues is essential for maintaining optimal performance. Understanding common problems and their symptoms can significantly simplify the process of identifying faults. This section will outline various methods to troubleshoot and resolve engine-related complications.

Start with Visual Inspection

Begin by examining the engine and surrounding components for visible signs of wear or damage. Look for leaks, loose connections, or frayed wires. Any unusual odors or noises can also indicate underlying issues that require attention.

Check Fuel System

The fuel system is often a primary source of complications. Ensure that the fuel is clean and fresh, and verify that the fuel filter is not clogged. Inspect fuel lines for cracks or leaks, as these can hinder performance and lead to starting difficulties.

Inspect the Air Filter

A clogged air filter can restrict airflow, causing the engine to struggle. Remove the air filter and clean it if necessary, or replace it if it shows signs of significant dirt accumulation. Proper airflow is crucial for efficient combustion.

Examine the Spark Plug

The spark plug plays a vital role in ignition. Remove it and check for carbon buildup or damage. A clean and functioning spark plug is essential for reliable engine start and operation. Replace it if it’s worn or dirty.

Assess Electrical Components

Electrical issues can often lead to performance problems. Inspect the battery for charge and condition, and ensure all connections are secure. Test the ignition system to confirm that it is delivering adequate spark for combustion.

Monitor Engine Performance

Finally, pay attention to the engine’s performance during operation. Unusual vibrations, excessive smoke, or changes in power output can indicate specific issues that may need further investigation. Keeping a log of symptoms can assist in pinpointing the root cause.

Fixing Electrical Problems Easily

Addressing electrical issues can often seem daunting, but with a systematic approach, many common faults can be resolved without professional assistance. Understanding basic components and their functions lays the groundwork for efficient troubleshooting. This section will guide you through the steps to identify and fix typical electrical challenges effectively.

Identifying Common Issues

Before diving into repairs, it’s essential to pinpoint the symptoms. Common indicators include intermittent power, failure to start, or unexpected shut-offs. Inspecting wiring connections and checking for frayed or damaged cords are crucial first steps. Additionally, ensure that all switches and fuses are functioning properly. If a fuse blows, replacing it may solve the problem, but repeated failures could indicate a deeper issue.

Steps for Simple Fixes

Once you have identified the potential problems, you can proceed with repairs. Start by disengaging the power source to avoid hazards. Replace any faulty components and ensure all connections are secure. For minor issues, cleaning terminals and ensuring good contact can significantly enhance performance. After completing the fixes, reconnect the power and test functionality to confirm that the problem has been resolved.

Replacing Belts and Cables

Proper maintenance of drive components is essential for optimal performance and longevity of your equipment. This section focuses on the procedure for swapping out essential belts and cables, which play a crucial role in the functionality and efficiency of your machine.

Identifying When to Replace

Recognizing the signs that indicate the need for replacement is vital. Here are some common indicators:

- Visible wear or fraying on belts.

- Difficulty in engaging or disengaging mechanisms.

- Unusual noises during operation, such as squeaking or grinding.

- Loose or damaged cables affecting control responsiveness.

Replacement Process

Follow these steps to ensure a successful replacement:

- Gather necessary tools: wrenches, pliers, and replacement parts.

- Disconnect the power source to prevent accidents.

- Remove any covers or shields obstructing access to belts and cables.

- Carefully detach the worn components, noting their routing for accurate installation.

- Install the new belts and cables, ensuring they are properly tensioned and routed.

- Reassemble any removed components and reconnect the power source.

- Test the system to confirm everything operates smoothly.

Regular checks and timely replacements can help maintain performance and extend the lifespan of your equipment. Always consult specific guidelines for your model for best practices.

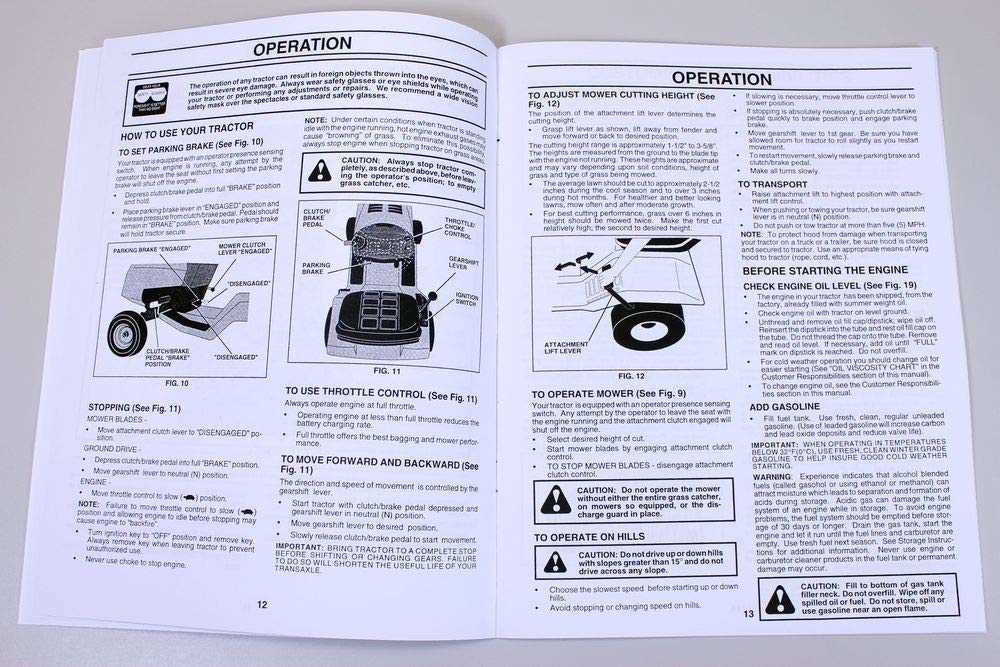

How to Adjust the Cutting Deck

Ensuring that your mowing apparatus operates at the correct height is essential for optimal performance and achieving a well-manicured appearance. Proper alignment and adjustment not only enhance the efficiency of the device but also prolong its lifespan. This guide outlines the necessary steps to effectively modify the cutting apparatus for superior results.

Step 1: Begin by positioning the machine on a flat, level surface to guarantee an accurate measurement of the cutting height. Check the manufacturer’s specifications for the ideal height range, as this can vary based on grass type and desired finish.

Step 2: Use a measuring tool to assess the current height of the blades from the ground. Adjusting the deck usually involves either raising or lowering it using the height adjustment lever or knobs located near the operator’s seat.

Step 3: If lowering the deck, ensure that the adjustment is done incrementally. Make small adjustments and recheck the height frequently to avoid cutting too low, which can damage the grass.

Step 4: Once the desired height is achieved, securely tighten all adjustment mechanisms to prevent shifting during operation. It is advisable to perform a test run to confirm that the blades are functioning properly and providing a uniform cut.

Step 5: After use, periodically inspect the cutting assembly for wear and tear. Keeping the blades sharp and well-maintained will contribute significantly to the overall performance and health of the lawn.

Understanding Hydrostatic Transmissions

Hydrostatic transmissions are essential components in various machinery, enabling smooth and efficient operation. They utilize fluid dynamics to transfer power, offering a seamless driving experience with precise speed control. This technology eliminates the need for complex mechanical linkages, making it a popular choice in numerous applications.

How Hydrostatic Systems Work

The principle behind hydrostatic systems involves a pump that generates hydraulic fluid flow, which is then directed to a motor. This interaction allows for variable speed and direction without the need for gear shifting. By adjusting the fluid flow, operators can easily control movement and responsiveness, enhancing usability in diverse conditions.

Advantages of Hydrostatic Transmissions

One of the key benefits of hydrostatic systems is their ability to provide smooth acceleration and deceleration. Additionally, they require less maintenance compared to traditional mechanical systems, reducing downtime and repair costs. The compact design also allows for greater flexibility in equipment layout, making them suitable for various tasks.

Winterizing Your Lawn Tractor

Preparing your outdoor machinery for the colder months is essential to ensure its longevity and optimal performance. By taking a few preventative measures, you can protect the engine and components from harsh weather and potential damage during the off-season.

Start by thoroughly cleaning the equipment to remove any dirt, debris, or grass clippings that could lead to rust or decay. After cleaning, inspect all fluids, including oil and fuel, and replace them as necessary to maintain peak efficiency. Emptying the fuel tank or adding a stabilizer will prevent fuel degradation and clogs.

Next, check the battery condition and clean any corrosion from the terminals. If the battery is removable, store it in a warm, dry location. Additionally, cover the equipment with a breathable tarp to shield it from moisture and dust, while still allowing air circulation.

Finally, consider inspecting and lubricating all moving parts to prevent seizing. A comprehensive check of belts, blades, and tires will help identify any wear and tear before the next season. Following these steps will keep your machinery in excellent condition and ready for use when warmer weather returns.

Finding Replacement Parts Online

Locating suitable components for your equipment has become increasingly convenient with the rise of online resources. By utilizing various platforms, users can easily access a wide range of parts, ensuring that their machines are well-maintained and functioning optimally.

Start by searching for specialized websites that cater to your specific brand or type of machinery. Many retailers offer extensive catalogs of parts, often accompanied by detailed descriptions and compatibility information. It’s advisable to take note of the part numbers or specifications from your device to streamline the search process.

Additionally, consider exploring auction sites and online marketplaces where both new and used items are available. These platforms can provide cost-effective alternatives, allowing you to find what you need at competitive prices. Always check the seller’s ratings and reviews to ensure a positive purchasing experience.

Don’t overlook community forums and social media groups dedicated to your equipment type. Engaging with fellow enthusiasts can yield valuable insights on sourcing hard-to-find parts and tips on installation or maintenance.

Safety Tips for DIY Repairs

When undertaking maintenance tasks on outdoor equipment, prioritizing safety is essential. Ensuring a secure working environment helps prevent accidents and injuries, enabling a smoother and more efficient process. Proper precautions and awareness of potential hazards can significantly enhance the overall experience.

First and foremost, always wear appropriate personal protective equipment (PPE). This includes safety goggles, gloves, and sturdy footwear to shield against sharp objects and heavy components. Additionally, working in a well-ventilated area is crucial to avoid inhaling harmful fumes or dust.

Before starting any task, thoroughly read the relevant documentation to understand the procedures and tools required. Make sure to disconnect the power source to prevent accidental starts while you work. Furthermore, keep your workspace tidy; removing clutter reduces the risk of tripping or misplacing tools.

Lastly, if you’re uncertain about any step in the process, don’t hesitate to seek guidance. Consulting with a knowledgeable friend or professional can provide valuable insights and ensure that you complete the task safely and effectively.