Understanding the complexities of advanced automotive systems is crucial for enthusiasts and professionals alike. This section aims to illuminate the essential aspects of a specific gearbox technology, shedding light on its operational intricacies and common issues that may arise. With a focus on practical insights, readers will gain a deeper appreciation of the components involved and their functionalities.

In the realm of vehicle mechanics, recognizing when intervention is necessary can significantly enhance performance and longevity. By delving into troubleshooting techniques and suggested practices, this guide seeks to empower individuals to address typical challenges effectively. Equipped with the right knowledge, one can navigate the intricacies of the system with confidence.

The journey through this informative segment will cover vital procedures, ensuring that users are well-prepared to tackle any difficulties. With a blend of theoretical understanding and hands-on strategies, readers will be better equipped to maintain their systems and keep their vehicles operating at peak efficiency.

ZF as Tronic Repair Manual

This section delves into the essential guidelines and insights for maintaining and troubleshooting the advanced transmission systems developed by ZF. Understanding these systems is crucial for optimal vehicle performance and longevity. The following points outline key aspects to consider for effective management of these complex components.

- System Overview: Familiarize yourself with the primary functions and architecture of ZF systems, including their electronic and mechanical interactions.

- Common Issues: Recognize typical problems that may arise, such as shifting irregularities and warning signals.

- Diagnostic Tools: Utilize specialized equipment for accurate assessment, including software applications and hardware interfaces.

For a successful approach, it’s important to follow systematic procedures during troubleshooting. Here are some recommended steps:

- Conduct a comprehensive diagnostic check to identify any existing faults.

- Review the vehicle’s service history to understand prior issues and maintenance practices.

- Inspect all relevant components thoroughly for wear and damage.

Proper maintenance practices are vital to ensuring reliability. Consider implementing the following:

- Regular Fluid Changes: Adhere to manufacturer guidelines for fluid replacement to prevent degradation.

- Software Updates: Keep electronic systems current to improve functionality and address potential vulnerabilities.

- Routine Inspections: Schedule periodic evaluations to catch minor issues before they escalate.

By adhering to these principles, you can enhance the performance and lifespan of ZF systems, ensuring they operate efficiently and effectively over time.

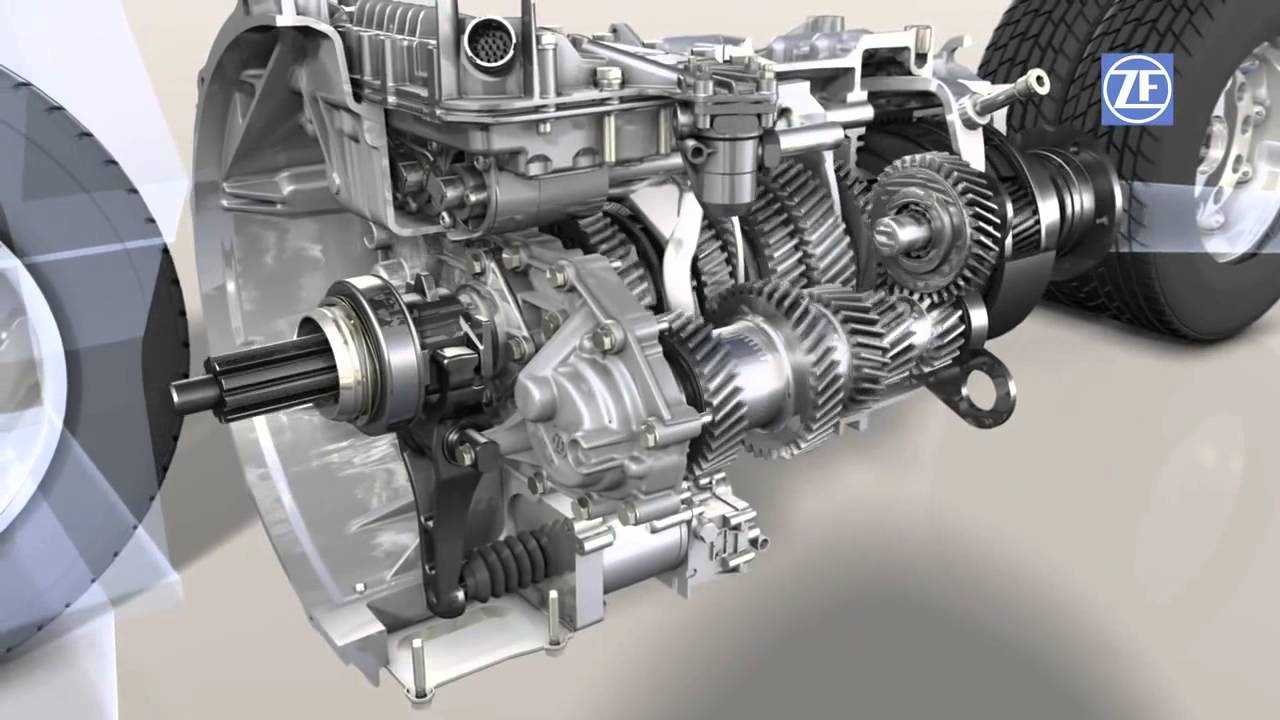

Understanding ZF As Tronic Systems

The ZF As Tronic systems represent an advanced approach to vehicle transmission technology, integrating automation and precision to enhance performance. This innovative solution aims to streamline gear shifting and improve overall driving experience, making it essential for modern automotive applications.

Key Features of ZF As Tronic Systems

- Automated Gear Shifting: Reduces the need for manual intervention, allowing for smoother transitions.

- Enhanced Fuel Efficiency: Optimizes engine performance by selecting the most suitable gear ratio.

- Improved Driving Comfort: Minimizes driver fatigue through seamless operation.

Components and Functionality

- Electronic Control Unit (ECU): Manages the overall operation of the system and coordinates gear changes based on driving conditions.

- Actuators: Responsible for executing the gear shifts as commanded by the ECU.

- Transmission Fluid System: Ensures proper lubrication and cooling of transmission components.

By understanding these systems, drivers and technicians can better appreciate the intricacies involved in modern vehicle performance and maintenance. This knowledge is vital for ensuring longevity and reliability in automotive operations.

Common Issues in ZF As Tronic

The ZF As Tronic system is known for its efficiency and performance, but like any complex mechanism, it can encounter various challenges. Understanding these common problems can help users and technicians address them promptly, ensuring optimal operation and longevity of the system.

- Shifting Delays: Users often report noticeable delays in gear changes, which can affect driving comfort and vehicle performance.

- Inconsistent Shifting: Irregular or unexpected gear changes may occur, leading to a lack of predictability while driving.

- Fluid Leaks: Hydraulic fluid leaks can lead to low fluid levels, affecting the system’s functionality and responsiveness.

- Warning Lights: Dashboard indicators may illuminate, signaling potential issues that require immediate attention.

- Overheating: Excessive heat can damage components, often caused by prolonged operation under heavy loads or insufficient cooling.

- Noise During Operation: Unusual sounds may indicate internal issues, such as wear or malfunctioning parts.

Addressing these challenges early can prevent more severe complications, ensuring the system remains reliable and efficient.

Step-by-Step Repair Process

This section provides a detailed approach to diagnosing and fixing common issues within the system. Each phase is designed to guide you through the necessary actions, ensuring clarity and efficiency in handling the components involved.

| Step | Description |

|---|---|

| 1 | Identify the symptoms. Gather information about the specific issues being experienced, such as unusual sounds or performance problems. |

| 2 | Conduct a preliminary inspection. Visually examine the system for any obvious signs of damage or wear. |

| 3 | Perform diagnostic tests. Utilize specialized tools to assess the functionality of various components. |

| 4 | Isolate the faulty parts. Based on test results, determine which components require attention or replacement. |

| 5 | Implement necessary fixes. Carefully replace or adjust components as indicated by your assessment. |

| 6 | Conduct final testing. After adjustments, run the system to verify that all issues have been resolved. |

| 7 | Document the process. Keep records of the steps taken and any parts replaced for future reference. |

Essential Tools for Repairing ZF As Tronic

When working on complex automotive systems, having the right equipment is crucial for effective maintenance and enhancement. This segment highlights the fundamental instruments necessary for tackling various challenges associated with the ZF As Tronic system.

Diagnostic Tools: Accurate assessment of electronic components is paramount. Specialized diagnostic devices can help identify faults and monitor system performance, ensuring that any underlying issues are addressed promptly.

Mechanical Instruments: A range of mechanical tools, including wrenches, sockets, and screwdrivers, are vital for disassembling and reassembling parts. Precision in handling these tools can prevent damage to sensitive components.

Calibration Equipment: Calibration tools are essential for ensuring that all electronic and mechanical systems function harmoniously. This includes pressure gauges and torque wrenches, which help achieve the manufacturer’s specifications.

Safety Gear: Protecting oneself while working is non-negotiable. Proper safety gear, including gloves, goggles, and masks, is necessary to shield against potential hazards during the process.

Investing in these essential tools not only facilitates efficient work but also enhances the longevity and reliability of the system. Proper preparation can make a significant difference in achieving successful outcomes.

Diagnostic Techniques for ZF Problems

Identifying issues in ZF systems requires a systematic approach, leveraging a variety of methods to pinpoint the root causes of malfunction. These techniques encompass both traditional diagnostics and advanced technologies, ensuring a comprehensive evaluation of the components involved.

One of the foundational techniques is the use of diagnostic tools to read error codes generated by the system. These codes provide invaluable insights into specific faults, facilitating a quicker resolution. In addition to error code analysis, visual inspections and functional tests play a critical role in assessing the performance of the system.

| Technique | Description |

|---|---|

| Error Code Reading | Utilizing specialized tools to extract diagnostic trouble codes for analysis. |

| Visual Inspection | Conducting a thorough examination of components for signs of wear or damage. |

| Functional Testing | Performing tests under various conditions to assess operational integrity. |

| Fluid Analysis | Checking the quality and condition of fluids to identify potential contaminants. |

| Pressure Testing | Measuring pressure levels in the system to detect leaks or blockages. |

By employing these diagnostic techniques, technicians can effectively uncover issues within ZF systems, leading to informed decisions on necessary actions for restoration.

Replacing Faulty Components Effectively

Addressing defective parts in a system requires a systematic approach to ensure optimal functionality. Identifying the root cause of the issue is crucial, as it allows for targeted interventions rather than generalized fixes. By focusing on specific elements that have malfunctioned, one can enhance the overall performance and longevity of the equipment.

Assessment is the first step in this process. It involves thorough diagnostics to determine which components are underperforming. Utilizing specialized tools and techniques can help pinpoint the problem areas accurately. This stage is essential to avoid unnecessary replacements and to maintain cost-efficiency.

Once the faulty elements are identified, the next phase is replacement. Selecting high-quality substitutes is paramount. Opting for components that meet or exceed the original specifications ensures compatibility and durability. It is advisable to consult with reliable suppliers and refer to technical specifications to make informed choices.

Installation of the new parts must be executed with precision. Following the manufacturer’s guidelines and best practices is vital to avoid future complications. Proper calibration and testing should follow to verify that the new components integrate seamlessly with the existing system.

Finally, it is important to document the entire process. Keeping detailed records of the assessments, replacements, and performance tests can aid in future maintenance and help track the effectiveness of the interventions made.

Preventive Maintenance Tips for Longevity

Maintaining the optimal performance of your vehicle requires regular attention and care. By implementing a few proactive measures, you can significantly extend its lifespan and enhance its reliability. Here are some essential strategies to consider for preserving your automobile’s functionality and efficiency.

Regular Inspections

- Schedule routine checks on fluid levels, including engine oil, coolant, and brake fluid.

- Inspect belts and hoses for signs of wear or damage.

- Monitor tire pressure and tread depth to ensure proper traction and fuel efficiency.

Routine Maintenance Tasks

- Change the engine oil and filter according to the manufacturer’s recommendations.

- Replace air filters regularly to maintain optimal engine performance.

- Keep the battery terminals clean and check the battery’s condition frequently.

- Flush and replace the coolant to prevent overheating and corrosion.

By following these preventive measures, you can help safeguard your vehicle against unexpected issues and maintain its performance for years to come.

Upgrading Your ZF As Tronic

Enhancing your ZF system can significantly improve performance and efficiency. This process involves several steps, from assessing your current setup to implementing advanced features that can optimize functionality. By following a structured approach, you can ensure that your vehicle operates at its best.

Benefits of Upgrading

- Improved shifting response

- Increased fuel efficiency

- Enhanced driving experience

- Access to modern features and technology

Steps for Enhancement

- Conduct a thorough evaluation of your current system.

- Research compatible upgrades available for your model.

- Consult with professionals or experienced enthusiasts for advice.

- Purchase quality components from reputable suppliers.

- Follow installation guidelines meticulously to ensure proper integration.

- Test the system to confirm improvements in performance.

By investing time and resources into upgrading your ZF setup, you can enjoy a more responsive and enjoyable driving experience.

Frequently Asked Questions About Repairs

This section addresses common inquiries regarding maintenance and troubleshooting, offering clarity on frequent concerns that arise during the process. Understanding these aspects can enhance efficiency and effectiveness in addressing issues.

General Queries

- What are the signs that indicate an issue?

- How can I diagnose a problem before seeking assistance?

- What tools do I need for basic assessments?

Procedural Insights

- Start with a visual inspection of components.

- Utilize diagnostic tools for precise information.

- Consult documentation for step-by-step guidance.

Resources for Further Learning

Expanding your knowledge in the field of vehicle systems can significantly enhance your understanding and skills. There are numerous materials and platforms available that cater to various levels of expertise, from beginners to seasoned professionals. Engaging with these resources will provide valuable insights and practical applications.

Online Courses and Tutorials

- Coursera: Offers a range of courses related to automotive technology and electronic systems.

- Udemy: Features practical video tutorials that cover specific components and diagnostics.

- YouTube Channels: Many experts share step-by-step guides and tips for troubleshooting systems.

Books and Publications

- Automotive Technology: A Systems Approach by Jack Erjavec: A comprehensive text covering various vehicle technologies.

- The Automotive Electronics Handbook by Ronald K. Jurgen: An in-depth resource on electronic components and their functions.

- Trade Magazines: Publications like “Automotive News” and “Motor Trend” offer articles on the latest advancements in vehicle technology.

Utilizing these resources can lead to a deeper comprehension and improved proficiency in managing modern automotive systems.