In every household, efficient appliances play a crucial role in simplifying daily chores. However, even the most reliable devices can encounter issues over time, leading to unexpected interruptions. This section aims to provide essential insights and guidance on addressing common problems associated with these invaluable tools.

Having a comprehensive resource at hand can significantly ease the burden of maintenance. By exploring various strategies and solutions, homeowners can empower themselves to tackle minor complications confidently. This knowledge not only extends the lifespan of appliances but also enhances their performance, ensuring smooth operation for years to come.

Whether it’s identifying the root cause of a malfunction or understanding the step-by-step process for restoration, being well-informed is key. Embracing a proactive approach allows individuals to handle situations efficiently, ultimately promoting a seamless experience in their everyday lives.

Common Issues with Kenmore Dishwasher

Many users encounter various challenges with their home cleaning appliances. Understanding these frequent problems can help in troubleshooting and maintaining optimal performance. Below are some of the most typical concerns that arise during usage.

Performance Problems

Issues related to efficiency are often reported. Some users experience inadequate cleaning, which may stem from improper loading or malfunctioning components. Recognizing these symptoms early can prevent further complications.

Noise and Leakage

Unusual sounds and water leaks can also be a source of frustration. Identifying the source of these issues is crucial for effective resolution. Regular checks can assist in preventing significant damage.

| Issue | Possible Cause | Solution |

|---|---|---|

| Poor Cleaning | Clogged spray arms | Clean or replace spray arms |

| Excessive Noise | Worn out motor | Inspect and replace motor if necessary |

| Water Leak | Damaged door seal | Replace the door gasket |

Step-by-Step Troubleshooting Guide

This section provides a systematic approach to identifying and resolving common issues encountered in your appliance. Following these steps will help ensure a thorough examination and facilitate effective solutions.

1. Check Power Supply: Ensure the unit is properly plugged in and that the outlet is functioning. Use a multimeter to confirm voltage if necessary.

2. Inspect Door Latch: Verify that the door is securely closed and the latch is functioning. A faulty latch can prevent operation.

3. Examine Water Supply: Ensure the water inlet valve is open and that there are no kinks in the supply line. Inspect the filter for any blockages.

4. Analyze Drainage: Check the drainage hose for clogs or kinks. Ensure the drain pump is operational by listening for unusual noises during operation.

5. Review Settings: Confirm that the selected cycle is appropriate for the load. Reset any error codes displayed on the control panel.

6. Assess Components: Inspect internal components such as the heating element and spray arms for wear or damage. Replace any defective parts as needed.

7. Consult Documentation: Refer to the user guide for specific error codes and their meanings, as well as additional troubleshooting steps tailored to your model.

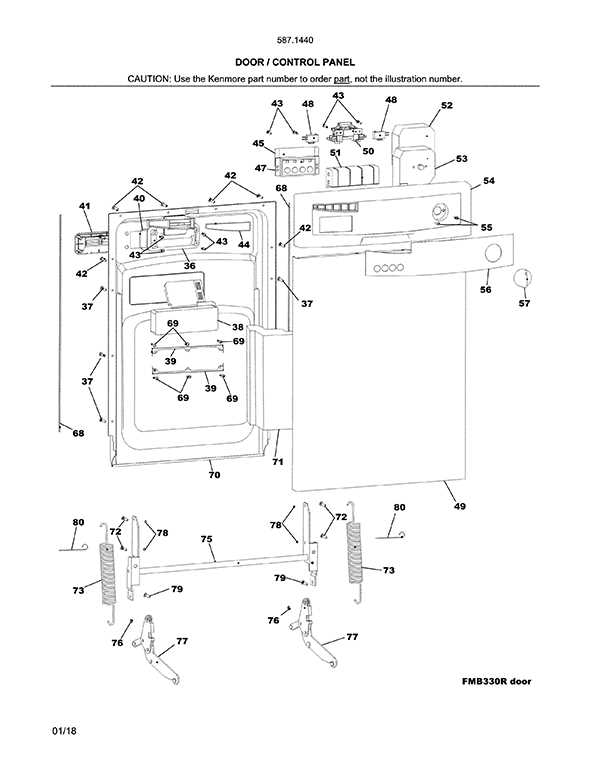

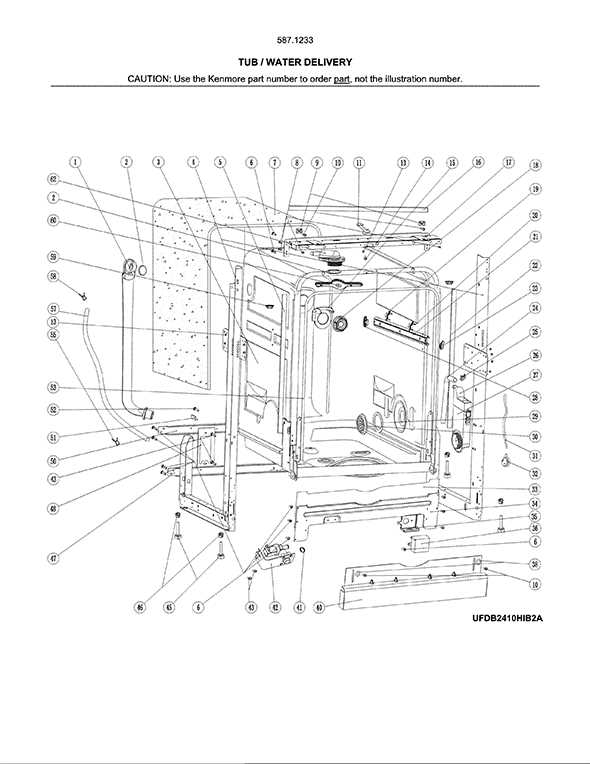

Parts Replacement for Model 587

This section focuses on the essential components that may need to be exchanged to ensure optimal functionality of the appliance. Understanding the various parts and their roles is crucial for maintaining efficiency and extending the lifespan of the unit.

Common Components to Replace

When addressing issues, certain elements are frequently identified as needing replacement. These may include the motor assembly, which is vital for driving the operation, and the door latch mechanism, ensuring secure closure during cycles. Regular inspection can prevent minor problems from escalating into major repairs.

Guidelines for Safe Replacement

It is essential to follow safety protocols when replacing parts. Always disconnect the unit from its power source before starting any work. Utilize the proper tools and consider consulting detailed instructions specific to the component being replaced. Proper care during this process can significantly impact performance and reliability.

Understanding the Control Panel Functions

The control interface of your kitchen appliance serves as the command center, allowing users to select desired operations and monitor performance. Familiarity with its layout and features enhances usability, ensuring optimal functionality for various tasks.

Key Features Overview

The panel typically includes buttons and indicators for initiating cycles, adjusting settings, and tracking progress. Each function is designed to cater to specific needs, from quick washes to intensive cleaning options. Understanding these elements helps users make informed choices.

Utilizing Settings Effectively

Many panels offer customizable options that enable users to tailor processes based on load size and soil level. Utilizing these settings not only improves efficiency but also conserves resources. Make sure to explore the full range of functions to maximize the performance of your unit.

Regular Maintenance Tips for Longevity

Ensuring the longevity of your kitchen appliance requires consistent care and attention. By adopting simple maintenance practices, you can enhance performance and prevent potential issues down the line. Regular upkeep not only extends the lifespan but also optimizes efficiency, leading to better results in everyday use.

Routine Cleaning Practices

- Wipe down the exterior regularly to prevent buildup of grime.

- Inspect and clean the interior components to eliminate residue and debris.

- Run a cleaning cycle with a dedicated solution to maintain freshness.

Component Checks

- Regularly inspect seals and gaskets for wear or damage.

- Check filters for clogs and clean them as needed to ensure proper flow.

- Examine hoses for leaks or cracks to avoid water damage.

Common Error Codes Explained

Understanding error codes can significantly enhance troubleshooting efficiency for household appliances. These codes provide valuable insights into underlying issues, enabling users to identify problems and implement solutions more effectively.

Below are some frequently encountered codes and their meanings:

- E1: Indicates a water supply issue. Check the inlet valve and hoses for blockages or kinks.

- E2: Signals a drainage problem. Inspect the drain pump and filter for debris that may obstruct flow.

- E3: Represents a heating element malfunction. Verify that the heating component is functioning correctly.

- E4: Denotes an overflow condition. Ensure that there are no leaks and the float switch is operational.

- E5: Suggests a sensor error. Check the wiring and connections associated with temperature sensors.

Addressing these codes promptly can prolong the lifespan of the appliance and enhance its performance. Always refer to the user guide for detailed instructions on troubleshooting specific error codes.

How to Clean Filters Effectively

Maintaining optimal performance in your appliance requires regular attention to its filtration system. Keeping filters clean ensures that debris and residue do not hinder functionality, ultimately extending the life of the unit.

Follow these steps for effective filter cleaning:

- Turn off the appliance and unplug it for safety.

- Locate the filters, typically found at the bottom or inside the main compartment.

- Remove the filters gently, ensuring not to damage any surrounding components.

Once you have the filters out, you can proceed with the cleaning process:

- Rinse the filters under warm running water to remove loose particles.

- Use a soft brush or sponge with mild soap to scrub away stubborn grime.

- Rinse thoroughly to ensure all soap residue is eliminated.

- Allow the filters to air dry completely before reinserting them.

Regular cleaning of the filtration system will enhance performance and ensure the longevity of your appliance.

Diagnosing Drainage Problems

Identifying issues related to water expulsion is essential for maintaining optimal appliance performance. Various factors can contribute to improper drainage, leading to pooling or insufficient water removal. Understanding these elements can help streamline troubleshooting efforts and restore functionality.

Step 1: Check for Blockages

Begin by inspecting the drain area for any visible obstructions. Common culprits include food particles, debris, or foreign objects that may impede the flow of water. Clear any blockages to ensure a free passage for drainage.

Step 2: Inspect Hoses

Examine the hoses connected to the appliance for kinks, cracks, or signs of wear. A damaged hose can restrict water flow and lead to drainage issues. Replace any compromised hoses to restore proper functionality.

Step 3: Assess the Pump

The pump plays a crucial role in expelling water. Listen for unusual noises during operation, which may indicate a malfunction. If the pump is silent or not functioning, it may require cleaning or replacement to ensure effective drainage.

Step 4: Evaluate the Filter

A clogged filter can also contribute to drainage problems. Remove and clean the filter regularly to prevent buildup that could hinder performance. Ensure it is properly reinstalled to maintain efficiency.

By following these diagnostic steps, one can effectively address and resolve drainage challenges, ensuring the appliance operates smoothly.

Safe Electrical Connection Practices

Ensuring secure and reliable electrical connections is crucial for the longevity and functionality of any appliance. Proper techniques not only enhance performance but also minimize risks associated with electrical faults. This section outlines essential practices for maintaining safety during the installation or repair of electrical systems.

Understanding Voltage and Amperage

Before proceeding with any connection, it is vital to comprehend the specifications of the voltage and amperage involved. Matching the correct values helps prevent overheating and potential damage to the components. Always consult relevant guidelines to ensure compatibility and avoid electrical hazards.

Using Proper Insulation and Tools

Employing appropriate insulation materials and tools is fundamental in establishing safe connections. Insulated wires and connectors protect against accidental contact and short circuits. Additionally, utilizing quality tools designed for electrical work ensures precision and enhances safety during the installation process.

Essential Tools for DIY Repairs

Embarking on a do-it-yourself project requires a set of fundamental instruments to ensure success. Having the right tools not only simplifies the task but also enhances the quality of the work done. This section will outline key items that every enthusiast should have on hand when tackling home appliance issues.

Basic Hand Tools

Start with a selection of hand tools, which form the backbone of any repair kit. A screwdriver set with various sizes and types is crucial, as is a wrench set to handle different fasteners. Don’t forget essential items like pliers and a utility knife, which provide versatility in numerous situations.

Specialized Equipment

In addition to standard tools, consider incorporating specialized equipment into your collection. A multimeter can assist in diagnosing electrical issues, while a socket set allows for easier access to tight spaces. For certain tasks, a heat gun or drill may also be invaluable, aiding in both removal and installation processes.