In the world of compact machinery, having access to detailed documentation is essential for ensuring optimal performance and longevity. This section aims to provide invaluable insights into the upkeep and diagnostics of specialized equipment, equipping operators with the knowledge needed to address various challenges that may arise during usage.

Understanding the intricacies of your machinery allows for proactive measures, minimizing downtime and enhancing efficiency. With a thorough exploration of essential procedures, users will be empowered to maintain their units effectively, ensuring they remain in peak condition throughout their operational lifespan.

This guide not only covers essential techniques for regular maintenance but also delves into common issues that operators may encounter. By familiarizing oneself with these aspects, users can approach troubleshooting with confidence, ultimately enhancing their overall experience and productivity.

Understanding Bobcat 2200 Maintenance

Proper upkeep of heavy machinery is essential for ensuring optimal performance and longevity. Regular attention to maintenance tasks not only enhances efficiency but also minimizes the risk of unexpected breakdowns. Familiarizing oneself with the specific requirements of the equipment can lead to smoother operations and lower overall costs.

Key Maintenance Practices

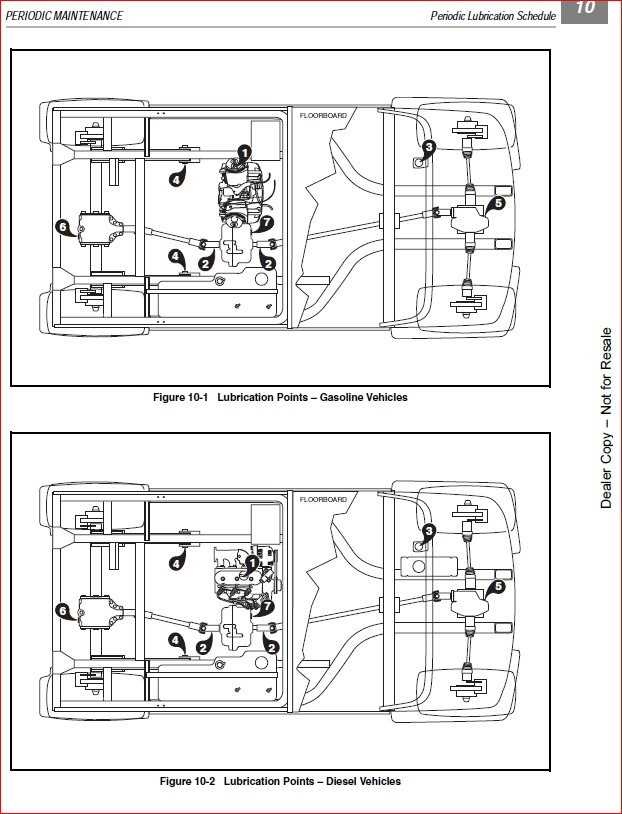

Regular inspections are vital to identify potential issues early on. Components such as hydraulic systems, filters, and belts should be routinely checked for signs of wear. Additionally, adhering to a consistent lubrication schedule helps maintain moving parts, reducing friction and prolonging their lifespan.

Benefits of Scheduled Upkeep

Engaging in a structured maintenance routine can lead to improved reliability and performance. Preemptive care not only extends the lifespan of machinery but also enhances safety for operators. By investing time in maintenance, users can avoid costly repairs and ensure their equipment remains in peak condition.

Essential Tools for Repairs

Having the right instruments is crucial for effectively addressing maintenance tasks on heavy machinery. A well-equipped toolkit not only enhances efficiency but also ensures the longevity of the equipment. Various categories of tools are necessary to cover different aspects of servicing, from basic hand tools to specialized devices.

Basic hand tools such as wrenches, screwdrivers, and pliers form the foundation of any toolkit. These are essential for performing standard adjustments and fastener management. Additionally, diagnostic equipment plays a vital role in identifying issues accurately, allowing for informed decisions regarding troubleshooting and component replacement.

Moreover, safety gear should not be overlooked. Proper personal protective equipment, including gloves, goggles, and helmets, ensures the well-being of the technician while working on the machinery. Investing in quality tools not only aids in performing tasks efficiently but also contributes to the overall reliability of the equipment in the long run.

Common Issues and Solutions

This section addresses frequent challenges encountered during maintenance of compact utility vehicles. Understanding these problems can help operators and technicians effectively diagnose and resolve issues, ensuring optimal performance and longevity of the equipment.

Below is a table summarizing typical problems along with their corresponding solutions:

| Issue | Solution |

|---|---|

| Engine won’t start | Check fuel level and battery charge; inspect starter connections. |

| Hydraulic system leaks | Examine hoses and connections; replace damaged components. |

| Poor lifting capability | Inspect hydraulic fluid levels; clean or replace filters. |

| Noisy operation | Check for loose parts; lubricate moving components. |

Safety Precautions During Service

Ensuring a secure working environment is crucial when performing maintenance on heavy machinery. Adhering to specific guidelines minimizes risks and promotes efficiency. Here are essential considerations to keep in mind.

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and helmets.

- Ensure the work area is clean and free from hazards, such as spills or loose tools.

- Disconnect the power source before beginning any maintenance tasks to prevent accidental activation.

- Use proper lifting techniques and equipment when handling heavy components.

- Familiarize yourself with the equipment’s emergency shut-off procedures.

By following these precautions, operators can safeguard themselves and others, ensuring a smoother and safer experience during maintenance activities.

Step-by-Step Repair Procedures

This section provides a detailed approach to effectively addressing maintenance and troubleshooting tasks for your equipment. Following systematic guidelines can enhance efficiency and ensure reliable performance.

Before beginning any task, gather the necessary tools and materials. This preparation is crucial for a seamless process.

- Assess the Issue:

- Identify the symptoms of the malfunction.

- Consult the appropriate documentation for initial insights.

- Gather Tools:

- Collect the required tools for the job.

- Ensure all safety equipment is available.

- Disassemble Components:

- Carefully remove any covers or panels.

- Take note of the assembly for easier reassembly.

- Inspect and Replace Parts:

- Check for wear or damage on critical components.

- Replace any faulty elements with new or refurbished parts.

- Reassemble the Unit:

- Carefully put back all removed components.

- Ensure that all connections are secure and intact.

- Test the Equipment:

- Power on the unit and monitor its performance.

- Verify that the issue has been resolved.

Following these structured steps will help in effectively managing maintenance tasks and ensuring optimal functionality.

Checking Fluid Levels and Quality

Maintaining proper fluid levels and assessing their quality is essential for optimal equipment performance and longevity. Regular checks can help prevent mechanical issues and ensure smooth operation. This section outlines the procedures for evaluating various fluids in your machinery.

Follow these steps to check fluid levels and their condition:

- Identify the fluids that require monitoring, such as:

- Hydraulic fluid

- Engine oil

- Coolant

- Transmission fluid

- Hydraulic fluid should be clear and not cloudy.

- Engine oil should be amber and free of debris.

- Coolant should be bright and free from rust.

- Transmission fluid should be red or pink and should not have a burnt smell.

Regular monitoring of fluid levels and quality not only enhances performance but also extends the lifespan of the equipment. Be proactive in maintaining these essential components.

Electrical System Troubleshooting

Diagnosing issues within the electrical framework of a machine is crucial for ensuring optimal functionality and longevity. This section focuses on identifying common problems, understanding their causes, and implementing effective solutions to restore performance.

Identifying Common Electrical Issues

Several symptoms may indicate an electrical malfunction, such as flickering lights, failure to start, or inconsistent power delivery. By systematically checking connections, components, and circuits, one can pinpoint the root cause of the problem.

Steps for Effective Troubleshooting

Begin with visual inspections of wiring and connectors, looking for signs of wear or damage. Utilize diagnostic tools to measure voltage and resistance at various points in the system. Document findings to track patterns and help in decision-making for repairs or replacements.

Parts Replacement Guidelines

Replacing components in machinery is a critical process that ensures optimal performance and longevity. Following precise protocols can help maintain functionality and prevent further issues. It is essential to identify which elements need replacement and to understand the procedures involved in the process.

Before beginning any replacement, it is advisable to gather the necessary tools and components. This preparation minimizes downtime and facilitates a smoother workflow. Always consult the relevant documentation to confirm specifications and compatibility of the new parts.

Steps for Effective Replacement:

- Disconnect the power source to prevent any accidental operation.

- Carefully remove the faulty component by following the outlined procedures.

- Inspect surrounding areas for any additional wear or damage.

- Install the new part securely, ensuring it is properly aligned and fitted.

- Reconnect the power and conduct tests to verify functionality.

Following these guidelines will help ensure that replacements are done efficiently and effectively, contributing to the overall reliability of the equipment.

Engine Performance Optimization

Enhancing the efficiency and power output of an engine involves a variety of strategies aimed at maximizing its capabilities. This process encompasses fine-tuning various components and ensuring that the entire system operates harmoniously. By focusing on critical aspects, one can significantly improve both performance and fuel efficiency.

Key Strategies for Enhancement

Implementing specific modifications, such as upgrading the air intake system, can lead to improved airflow and better combustion. Additionally, adjusting fuel delivery parameters ensures that the engine receives the optimal mix for peak performance. Regular maintenance checks, including oil changes and filter replacements, also play a crucial role in sustaining engine health.

Monitoring and Diagnostics

Utilizing diagnostic tools allows for real-time monitoring of engine performance metrics. By analyzing data such as RPM, temperature, and exhaust emissions, one can identify potential issues and rectify them promptly. Consistent evaluation not only aids in maintaining optimal function but also extends the longevity of the engine.

Seasonal Maintenance Tips

Regular upkeep is essential to ensure optimal performance throughout the year. Each season presents unique challenges that can impact machinery efficiency. By following tailored maintenance practices, you can enhance longevity and reliability.

- Spring:

- Inspect hydraulic fluids and replace if necessary.

- Check for wear on tires and ensure proper inflation.

- Clean air filters to promote efficient airflow.

- Summer:

- Monitor engine temperatures and coolant levels.

- Ensure all electrical connections are secure to prevent overheating.

- Lubricate moving parts to minimize friction.

- Fall:

- Prepare for colder weather by inspecting batteries.

- Clear debris from undercarriage and engine compartments.

- Check belts and hoses for signs of wear.

- Winter:

- Store equipment in a sheltered area when not in use.

- Use winter-grade fluids to prevent freezing.

- Inspect heating systems for proper functionality.

Implementing these practices will help maintain machinery in peak condition, ensuring reliable operation throughout the seasons.

Service Schedule Recommendations

Maintaining optimal performance of your equipment requires a structured approach to regular maintenance. Adhering to a well-planned timetable ensures longevity and reliability, minimizing unexpected failures.

Frequency of Inspections: It is advisable to conduct comprehensive evaluations every few months, depending on usage. Frequent checks allow for early detection of potential issues and enable timely interventions.

Essential Maintenance Tasks: Key activities include fluid changes, filter replacements, and component inspections. Each task plays a crucial role in ensuring the machinery operates smoothly and efficiently.

Seasonal Considerations: Adjust maintenance practices according to seasonal changes. Preparing equipment for varying weather conditions enhances performance and reduces wear.

Resources for Further Assistance

Accessing reliable information is crucial for maintaining and troubleshooting equipment effectively. Various resources are available to enhance understanding and support users in addressing common challenges. These materials can provide invaluable insights and guidance for both novice and experienced operators.

Online Forums and Communities offer a platform for users to share experiences, ask questions, and receive advice from fellow enthusiasts and professionals. Engaging in discussions can lead to practical solutions and innovative techniques that may not be found in traditional literature.

Manufacturer Websites often contain a wealth of resources, including downloadable documents, instructional videos, and FAQs. These sites are typically updated with the latest information, ensuring that users have access to current best practices and specifications.

Technical Publications, such as journals and industry magazines, can provide in-depth articles on maintenance practices, industry standards, and advancements in technology. Subscribing to relevant publications can keep users informed about new developments and techniques.

Utilizing these resources can significantly improve proficiency and confidence when dealing with equipment, ensuring optimal performance and longevity.