Understanding the intricacies of outdoor equipment is essential for achieving optimal performance and longevity. Whether you’re facing minor issues or significant challenges, having access to detailed guidance can make all the difference. This section aims to equip you with the necessary knowledge to effectively address common problems and enhance the functionality of your tools.

In this informative resource, you’ll discover practical insights into diagnosing and resolving typical malfunctions. From step-by-step instructions to valuable tips, the content is designed to empower you to take control of maintenance tasks with confidence. With a focus on clarity and usability, this guide will serve as your go-to reference for keeping your equipment in top shape.

Engaging with the material will not only enhance your understanding but also foster a sense of accomplishment as you navigate through various procedures. Prepare to dive into the essentials that will help you maintain peak performance and ensure the reliability of your outdoor machinery.

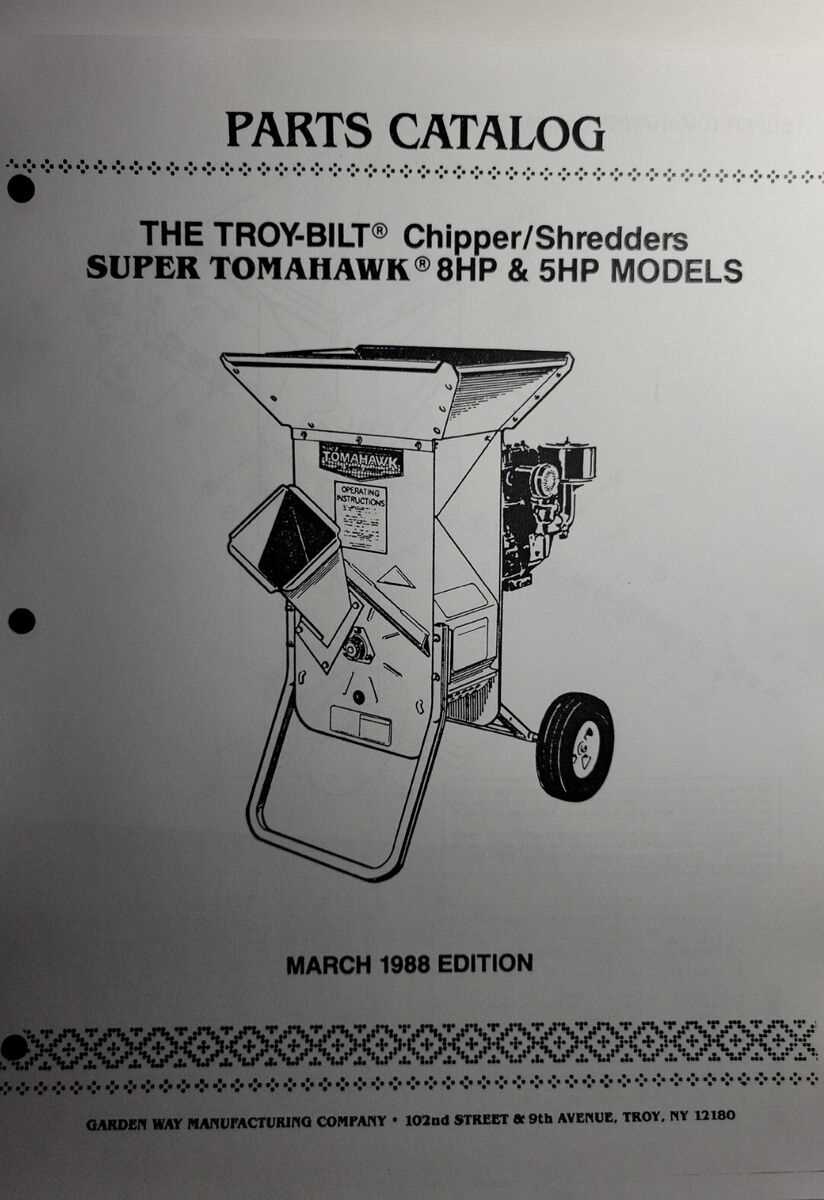

Troy Bilt TB685EC Overview

The model in focus represents a blend of efficiency and reliability, designed to tackle a variety of outdoor tasks with ease. Its construction emphasizes durability, making it suitable for both professional and residential use. This equipment is equipped with features that enhance user experience and ensure optimal performance.

With a powerful engine at its core, this device excels in delivering consistent results. The ergonomic design allows for comfortable handling, reducing fatigue during extended use. Additionally, it incorporates advanced technology to facilitate straightforward maintenance, ensuring longevity and dependability.

Users can expect versatility, as this model adapts well to different environments and job requirements. Whether it’s tackling thick underbrush or performing routine yard care, its design caters to diverse needs, making it a valuable asset for any outdoor project.

Common Issues and Solutions

When maintaining outdoor power equipment, users often encounter a variety of challenges that can hinder performance. Understanding these frequent problems and their respective remedies can significantly enhance the longevity and functionality of the machinery.

Frequent Problems

- Engine won’t start

- Loss of power during operation

- Unusual noises while running

- Difficulty in controlling the equipment

- Excessive vibration

Potential Solutions

- Engine won’t start: Check the fuel level and ensure the fuel is fresh. Inspect the spark plug for wear and replace if necessary.

- Loss of power during operation: Clean or replace the air filter to improve airflow and check the fuel filter for clogs.

- Unusual noises while running: Tighten any loose bolts and inspect the blades for damage or debris.

- Difficulty in controlling the equipment: Ensure that all control cables are properly adjusted and lubricated.

- Excessive vibration: Check for worn or damaged components, and balance the blades if necessary.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and efficient performance of any outdoor equipment. By following a few key practices, users can significantly extend the life of their machines and enhance their functionality over time.

Regular Cleaning: Keeping the equipment clean is vital. Remove any debris, dirt, or grass clippings after each use. This prevents buildup that can cause wear and tear.

Check and Change Fluids: Regularly inspect and replace the engine oil and other fluids as recommended. Fresh fluids ensure smooth operation and reduce the risk of mechanical failure.

Inspect Blades and Filters: Ensure that blades are sharp and free from damage. Additionally, check air and fuel filters periodically, replacing them when necessary to maintain optimal performance.

Store Properly: When not in use, store the equipment in a dry, sheltered area. Protecting it from harsh weather conditions can prevent rust and other forms of deterioration.

Follow Manufacturer Guidelines: Adhering to the manufacturer’s specifications for maintenance and usage is crucial. These guidelines provide essential information on how to care for the equipment effectively.

Essential Tools for Repairs

Having the right equipment is crucial for effective maintenance and troubleshooting of any outdoor machinery. This section outlines the fundamental instruments that can facilitate a smoother process and ensure successful outcomes.

- Screwdrivers: Both flathead and Phillips screwdrivers are essential for accessing various components.

- Wrenches: A set of adjustable wrenches and socket sets will help with loosening and tightening bolts.

- Pliers: Needle-nose and slip-joint pliers are useful for gripping and bending tasks.

- Multimeter: This device is vital for diagnosing electrical issues by measuring voltage and resistance.

- Oil and Grease: Lubricants are necessary for ensuring smooth operation and prolonging the life of moving parts.

- Cleaning Supplies: Brushes and cloths will assist in maintaining a clean working environment.

Equipping yourself with these tools not only enhances efficiency but also contributes to a better understanding of the machinery’s functionality.

Step-by-Step Repair Guide

This section provides a comprehensive approach to addressing common issues encountered with the equipment. By following a systematic process, you can effectively troubleshoot and resolve various malfunctions, ensuring optimal performance and longevity.

1. Initial Assessment: Begin by examining the unit for visible signs of damage or wear. Check for loose components, leaks, or any unusual noises. Document your findings to guide further actions.

2. Gather Tools and Parts: Assemble all necessary tools and replacement components before starting the procedure. This preparation will streamline the process and reduce downtime.

3. Disassembly: Carefully take apart the relevant sections of the device, following the sequence outlined in your documentation. Ensure that you keep track of all screws and small parts to avoid misplacement.

4. Inspection: Once disassembled, thoroughly inspect internal parts for any signs of damage or excessive wear. Pay close attention to belts, gears, and electrical connections.

5. Replacement: If any components are found to be defective, replace them with new parts. Ensure that all replacements are compatible with the specific model to prevent further issues.

6. Reassembly: Carefully reassemble the unit, ensuring that each component is securely fastened. Double-check that all parts are aligned correctly before tightening screws.

7. Testing: After reassembly, conduct a thorough test to verify that the equipment operates as expected. Monitor for any irregularities and make adjustments as necessary.

8. Final Checks: Perform a final inspection to ensure all tools have been removed and that the area is clean. Document the completed work for future reference.

Understanding the Engine Components

Gaining insight into the various components of a power unit is essential for effective maintenance and troubleshooting. Each element plays a vital role in the overall functionality, ensuring optimal performance and longevity. Recognizing how these parts interact can significantly enhance repair efforts and improve operational efficiency.

Key Parts of the Power Unit

At the heart of the system lies the cylinder, which is responsible for the combustion process. This is where fuel mixes with air and ignites, producing the power necessary for operation. Surrounding this core element are various supportive components such as the piston and crankshaft, which convert this energy into mechanical motion.

Fuel and Ignition Systems

The fuel system is crucial for delivering the right mixture of gasoline and air to the combustion chamber. This system includes the fuel tank, lines, and filter, all of which must be in good condition for proper function. Meanwhile, the ignition system is responsible for sparking the fuel-air mixture, utilizing components like spark plugs and coils to ensure efficient combustion.

Replacing Worn-Out Parts

Over time, various components of outdoor equipment can degrade, leading to decreased performance and reliability. It is essential to identify and replace these elements to ensure the machine functions optimally. Addressing wear and tear proactively can extend the lifespan of your device and improve its efficiency.

Here are some common parts that may require attention:

- Blades: Dull or damaged blades can hinder cutting efficiency. Regularly inspect and replace them as needed.

- Filters: Clogged air and fuel filters can restrict airflow and fuel supply, leading to poor performance. Change these regularly.

- Belt: A worn-out belt can affect power transmission, causing slippage or noise. Check for signs of wear and replace if necessary.

- Spark Plug: A faulty spark plug can lead to starting issues. Replacing it can improve ignition and overall engine performance.

To replace a worn part, follow these steps:

- Turn off the engine and disconnect the spark plug wire for safety.

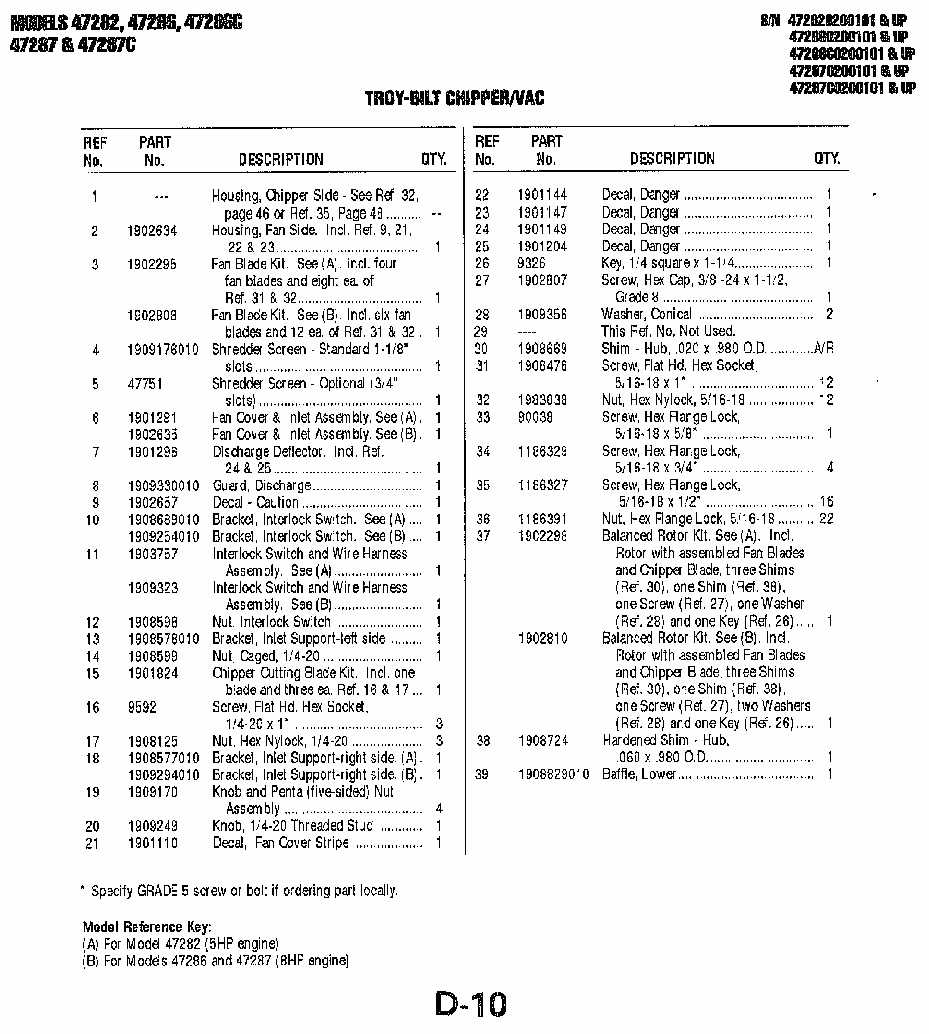

- Refer to the specific component guide to locate the part needing replacement.

- Use appropriate tools to remove the worn part.

- Install the new part, ensuring it is secured properly.

- Reconnect the spark plug wire and test the equipment to ensure it operates smoothly.

Regular maintenance and timely replacements can significantly enhance the functionality of your outdoor equipment, ensuring it meets your needs effectively.

Safety Precautions During Repairs

Ensuring personal safety and the protection of equipment is paramount when performing maintenance tasks. Adhering to specific guidelines can minimize risks and prevent accidents, ultimately leading to a more effective and efficient process. Awareness of the environment and proper handling of tools contribute significantly to a safe working atmosphere.

Personal Protective Equipment

Wearing appropriate protective gear is essential. This includes gloves to shield hands from sharp objects, safety glasses to protect eyes from debris, and sturdy footwear to guard against falling items. Additionally, using ear protection can help reduce the risk of hearing damage from loud machinery.

Tool Handling and Workspace Organization

Keeping tools in good condition and properly organized is crucial. Regularly inspecting equipment for wear or damage can prevent malfunctions. A clutter-free workspace reduces hazards, making it easier to navigate and minimizing the risk of tripping or dropping tools. Always ensure that electrical devices are unplugged before conducting any adjustments.

Troubleshooting Electrical Problems

When facing issues with electrical systems, a systematic approach can help identify and resolve faults effectively. Understanding the common signs of electrical malfunctions is crucial for efficient diagnosis. This section outlines key steps to help pinpoint and address these problems, ensuring that equipment operates smoothly.

Start by inspecting all connections for signs of wear or corrosion. Loose wires or poor connections can lead to intermittent functionality. Ensure that all plugs are secure and that terminals are free from rust or debris. Additionally, use a multimeter to check voltage levels across critical components, verifying that they meet the required specifications.

If the system fails to power on, verify that the battery or power source is functioning correctly. Replace any blown fuses and consider testing with a known-good battery to rule out power issues. Pay attention to any unusual sounds or smells that may indicate a short circuit or component failure.

Finally, consult any available schematics to understand the wiring layout and component relationships. This will aid in identifying potential problem areas and guide further testing or replacement of faulty components. By following these troubleshooting steps, you can effectively address electrical challenges and restore functionality.

Proper Fuel and Oil Usage

Ensuring optimal performance of your outdoor equipment requires careful attention to the types of fuel and lubricant used. Selecting the right products not only enhances efficiency but also prolongs the lifespan of the machine. This section will guide you through the essentials of fuel and oil specifications to keep your equipment running smoothly.

Choosing the Right Fuel

For optimal performance, always use fresh, high-quality fuel. A mixture of gasoline with the correct octane rating is essential. It’s recommended to avoid using fuels with ethanol content higher than 10%, as this can lead to issues such as corrosion and poor combustion. Additionally, using a fuel stabilizer can help maintain fuel quality, especially if the machine will not be used for an extended period.

Oil Specifications and Maintenance

Lubrication is crucial for the proper functioning of engine components. Always refer to the manufacturer’s specifications for the appropriate oil type and viscosity. Synthetic oils are often preferred due to their superior protective qualities and resistance to breakdown. Regularly check oil levels and change the oil as indicated in the maintenance schedule to ensure your equipment operates at peak performance.

FAQs About Troy Bilt TB685EC

This section addresses common inquiries related to the model, providing valuable insights for users and enthusiasts. Understanding typical concerns can enhance the experience of maintaining and utilizing this equipment.

What should I do if my machine won’t start?

If the unit fails to start, check the fuel level, ensure the spark plug is clean, and verify that the ignition switch is in the ‘on’ position. Regular maintenance can prevent many starting issues.

How often should I change the oil?

It is recommended to change the oil after every 20-50 hours of operation, or at least once per season. Clean oil promotes better performance and longevity.

What type of fuel should I use?

Utilize fresh, unleaded fuel with an octane rating of 87 or higher for optimal performance. Avoid using fuel containing ethanol over 10% to prevent potential engine issues.

How can I troubleshoot a loss of power?

A loss of power may be due to a clogged air filter or spark plug. Inspect and clean or replace these components as necessary to restore efficiency.

Where can I find replacement parts?

Replacement components can typically be found at local hardware stores or through authorized dealers online. Always ensure you are purchasing parts specifically designed for your equipment.