Ensuring the longevity and efficiency of your small engine requires a thorough understanding of its components and their proper upkeep. This section provides essential insights into troubleshooting common issues and implementing effective solutions, ultimately enhancing performance and reliability.

From routine checks to more intricate adjustments, maintaining your engine can be a rewarding endeavor. Whether you’re dealing with ignition troubles or fuel system concerns, having access to clear, step-by-step instructions is crucial for successful restoration and optimal functionality.

By familiarizing yourself with the intricacies of your engine’s design and operational principles, you can confidently address problems as they arise. This guide serves as a valuable resource, equipping you with the knowledge needed to tackle maintenance tasks and extend the lifespan of your equipment.

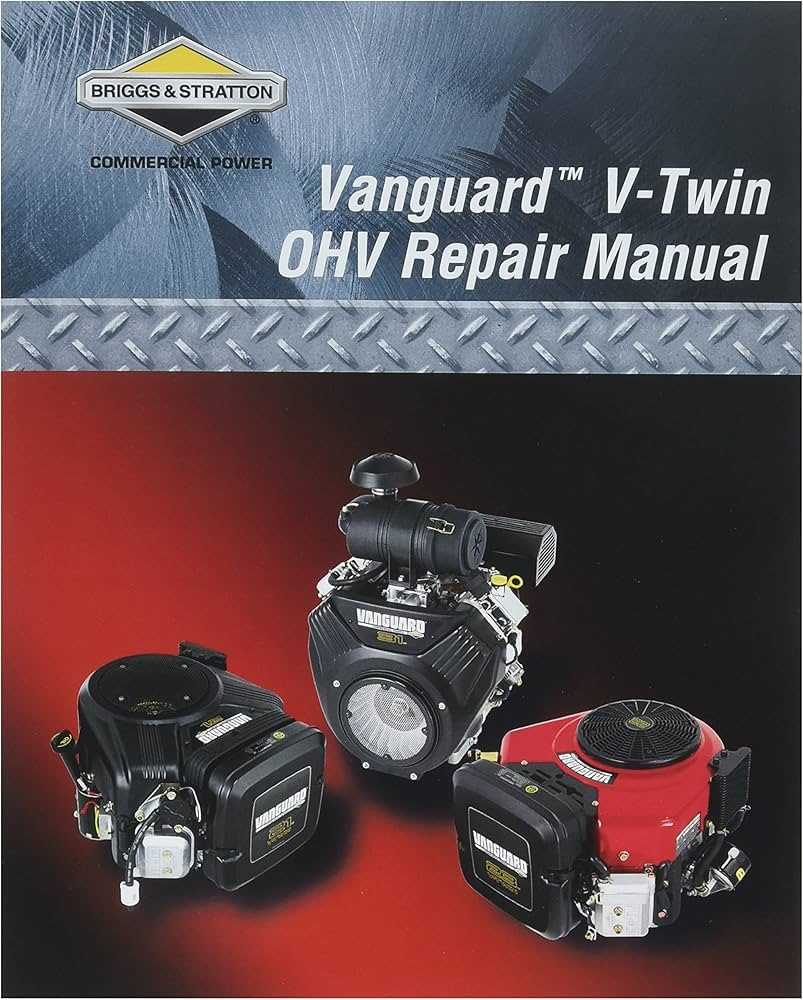

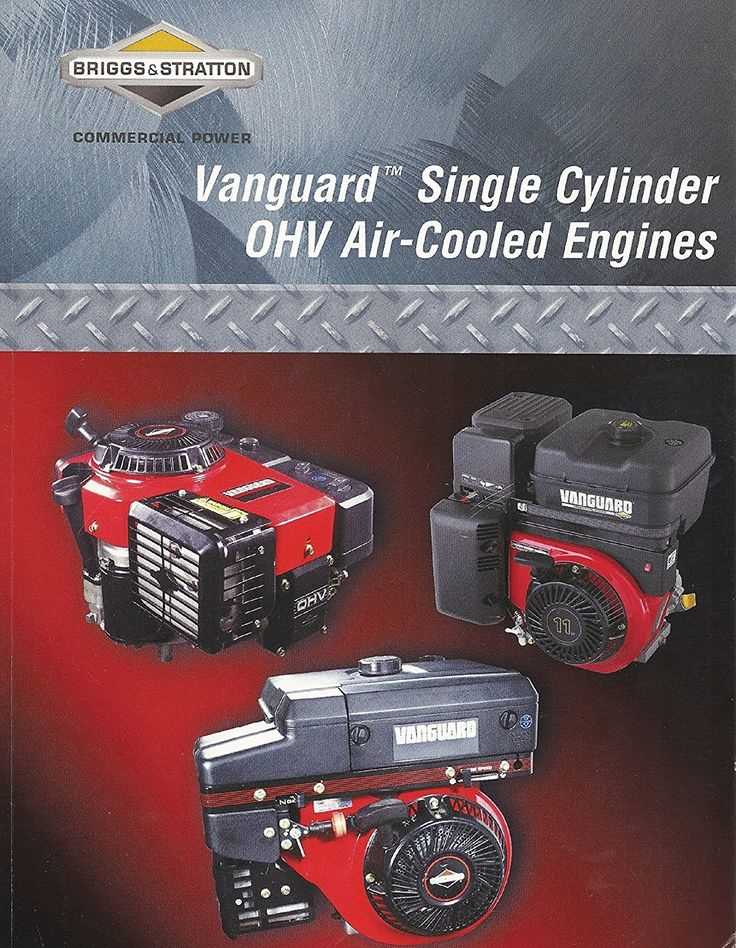

Understanding Briggs OHV Engines

This section explores the essential features and operational principles of a specific type of small internal combustion engine, known for its efficiency and durability. By delving into its components and functionality, users can gain valuable insights that will aid in proper maintenance and troubleshooting.

Key Features

- Compact Design: These engines are engineered to occupy minimal space while delivering optimal performance.

- Fuel Efficiency: They are designed to maximize fuel utilization, reducing costs for the user.

- Low Emissions: The design focuses on minimizing environmental impact through reduced exhaust output.

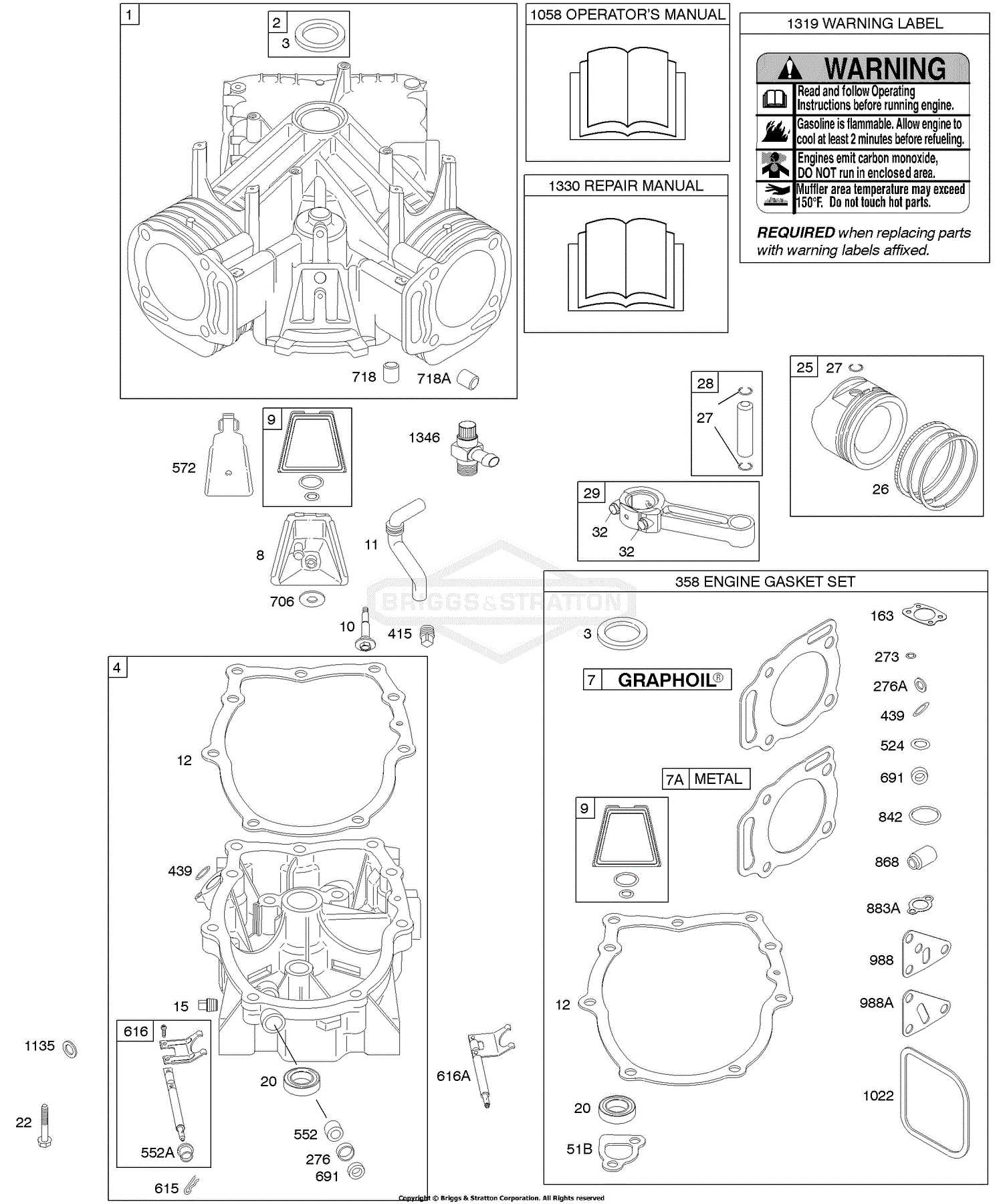

Main Components

- Cylinder: The heart of the engine where combustion occurs, playing a crucial role in power generation.

- Piston: Moves within the cylinder, converting combustion energy into mechanical motion.

- Crankshaft: Transforms the linear motion of the piston into rotational energy used to drive machinery.

- Valves: Control the intake of fuel and air, as well as the expulsion of exhaust gases.

Understanding these features and components is vital for anyone looking to maintain or troubleshoot these engines effectively.

Common Issues with OHV Models

Engines featuring overhead valve designs are known for their efficiency and performance. However, like any mechanical system, they can encounter various challenges over time. Understanding these common problems can help in maintaining optimal functionality and longevity.

- Fuel Delivery Problems:

- Clogged fuel lines can hinder the flow, causing performance issues.

- Contaminated fuel may lead to starting difficulties and poor combustion.

- Starting Difficulties:

- Weak or dead batteries can prevent ignition.

- Faulty spark plugs often result in unreliable starts.

- Overheating:

- Low coolant levels can cause excessive heat buildup.

- Blocked air filters may restrict airflow, leading to overheating.

- Oil Leaks:

- Worn gaskets can result in oil escaping from the engine.

- Poor seals may also contribute to oil leakage issues.

- Vibration and Noise:

- Loose components can create excessive noise during operation.

- Unbalanced parts may lead to vibrations affecting performance.

Identifying these issues early can prevent more serious damage and ensure smooth operation of your engine. Regular maintenance checks are essential for addressing these common concerns.

Tools Needed for Repairs

Undertaking maintenance or restoration tasks requires a variety of essential instruments to ensure efficiency and precision. Having the right equipment at hand not only simplifies the process but also enhances the quality of the work. This section outlines the necessary tools that will aid in effective service and adjustment.

Essential Instruments

The following list details the key items that are commonly needed for tasks involving mechanical components:

| Tool | Description |

|---|---|

| Socket Set | A collection of sockets and ratchets for loosening and tightening fasteners. |

| Wrenches | Various sizes of wrenches for gripping and turning nuts and bolts. |

| Screwdrivers | Flathead and Phillips head screwdrivers for removing and securing screws. |

| Torque Wrench | An adjustable tool for applying a specific torque to fasteners. |

| Multimeter | A device for measuring electrical properties, essential for troubleshooting. |

Additional Supplies

In addition to the primary tools, having certain supplies on hand can facilitate smoother operations:

| Supply | Description |

|---|---|

| Lubricants | Oils and greases to reduce friction and ensure smooth operation. |

| Cleaning Solutions | Products to remove dirt and debris from components. |

| Replacement Parts | Spare components that may need to be exchanged during servicing. |

Step-by-Step Maintenance Guide

Regular upkeep is essential for ensuring optimal performance and longevity of your outdoor equipment. This guide provides clear instructions to help you systematically maintain your engine, enhancing its reliability and efficiency.

Essential Tools and Materials

- Wrench set

- Screwdrivers

- Oil and filter

- Air filter

- Spark plug

- Fuel stabilizer

Maintenance Steps

- Start by inspecting the exterior for any visible damage.

- Change the oil regularly to keep the engine lubricated.

- Replace the air filter to ensure proper airflow.

- Examine the spark plug and replace if worn.

- Clean the fuel system and add stabilizer to prevent degradation.

- Test the equipment to ensure all systems are functioning correctly.

How to Replace the Spark Plug

Replacing the spark plug is a vital maintenance task that can enhance engine performance and fuel efficiency. A worn or faulty spark plug can lead to starting issues, poor acceleration, and increased emissions. Ensuring this component is in optimal condition is essential for smooth operation.

Gathering Necessary Tools

Before starting the replacement process, collect the required tools. You will need a spark plug socket, a ratchet, a gap gauge, and, if necessary, a torque wrench. Having these items ready will streamline the task and prevent interruptions.

Steps to Replace the Spark Plug

Begin by disconnecting the ignition source to ensure safety. Remove the old spark plug by turning it counterclockwise with the spark plug socket. Inspect the electrode and the insulator for wear or damage. Next, check the gap using a gauge, adjusting it to the manufacturer’s specifications if needed. Install the new spark plug by threading it in place and tightening it firmly, but not overly tight, to avoid damaging the threads. Finally, reconnect the ignition source and start the engine to ensure everything is functioning properly.

Adjusting Valve Clearance Procedures

Properly setting the spacing between the engine’s valves and their corresponding components is essential for optimal performance. This adjustment ensures efficient operation, preventing potential damage and enhancing longevity. The following steps outline the procedure for achieving the correct clearance.

- Gather necessary tools, including a feeler gauge, wrenches, and a socket set.

- Ensure the engine is cool to avoid any inaccuracies caused by thermal expansion.

- Remove the engine cover to access the valve assembly.

- Rotate the crankshaft until the piston is at the top of its compression stroke.

- Check the clearance using the feeler gauge:

- Insert the gauge between the valve and the rocker arm.

- Determine if the gauge fits snugly; it should have a slight resistance.

- Clockwise to reduce the gap.

- Counterclockwise to increase the gap.

Finally, replace the engine cover and ensure all components are securely fastened. Regular maintenance of valve spacing contributes significantly to the engine’s efficiency and reliability.

Fuel System Troubleshooting Tips

Ensuring optimal performance in your engine often hinges on the effective operation of its fuel delivery system. Issues such as poor starting, stalling, or irregular power can stem from a variety of fuel-related problems. This section offers essential guidance for identifying and resolving common fuel system malfunctions.

Identifying Common Issues

Start by checking the fuel source. Ensure the tank is filled with fresh, clean fuel. Contaminated or old fuel can lead to significant performance issues. Next, examine the fuel lines for any signs of leaks, cracks, or blockages. These obstructions can severely hinder fuel flow, causing erratic engine behavior.

Examining Components

Pay special attention to the filter and carburetor. A clogged fuel filter can restrict flow, while a malfunctioning carburetor can disrupt the air-fuel mixture. Cleaning or replacing these components can often resolve performance issues. Additionally, inspect the fuel pump to ensure it is operating correctly, as a faulty pump can lead to inadequate fuel delivery.

Remember: Regular maintenance of the fuel system is key to avoiding complications and ensuring smooth operation.

Overheating Solutions for OHV Engines

Excessive heat in small power units can lead to serious performance issues and potential damage. It is essential to address overheating promptly to ensure the longevity and efficiency of the engine. Various factors contribute to this problem, and understanding these can help in implementing effective solutions.

Regular Maintenance: Routine checks on the cooling system, including cleaning air filters and ensuring proper airflow, are crucial. Debris accumulation can obstruct airflow, leading to increased temperatures.

Coolant Levels: Monitoring and maintaining appropriate coolant levels is vital. Low coolant can cause overheating, so regularly inspecting and refilling as necessary can mitigate this issue.

Fuel Quality: Using high-quality fuel can prevent engine knocking and overheating. Impurities in fuel may lead to inefficient combustion and excessive heat generation.

Engine Timing: Proper timing adjustments can improve efficiency and reduce the chances of overheating. Ensuring that ignition and valve timing are correctly set can help maintain optimal operating temperatures.

Temperature Monitoring: Installing a temperature gauge can provide real-time feedback on engine heat levels. This allows for timely intervention before overheating occurs.

Ventilation: Adequate ventilation is necessary for cooling. Ensuring that exhaust systems are functioning correctly and that there are no blockages can significantly reduce overheating risks.

By implementing these strategies, one can effectively manage and reduce overheating issues in small engines, ensuring reliable performance and extended service life.

Identifying Engine Noises

Recognizing the various sounds emitted by an engine is crucial for maintaining optimal performance and ensuring longevity. Each noise can signify different issues, helping users diagnose potential problems early. Understanding these sounds allows for timely intervention and can prevent more severe damage.

Common Sounds and Their Meanings

Engines may produce a range of noises, each with its unique implications. For instance, a knocking sound often indicates problems with internal components, such as worn bearings or insufficient lubrication. In contrast, a hissing noise might suggest a leak in the cooling system or exhaust. Paying attention to these auditory signals can guide users in troubleshooting effectively.

When to Seek Professional Help

While some noises can be addressed with basic maintenance, others may require expert attention. If unfamiliar or alarming sounds persist, it is advisable to consult a professional. Prompt action can mitigate the risk of further complications, ensuring the engine remains in peak condition.

Rebuilding the Carburetor Explained

Revitalizing the fuel delivery system is essential for optimal engine performance. This process involves disassembling the unit, cleaning the components, and reassembling them with precision. Understanding the steps involved ensures that the task is completed efficiently and effectively.

Here are the key steps to consider when overhauling the fuel delivery mechanism:

- Gather Necessary Tools: Ensure you have the right tools before starting. Common tools include:

- Screwdrivers

- Wrenches

- Cleaning brushes

- Compressed air

- Gaskets and seals

- Disassemble the Unit: Carefully take apart the mechanism, noting the order of components for reassembly.

- Inspect for Damage: Check each part for wear, cracks, or corrosion. Replace any faulty components as needed.

- Clean Thoroughly: Use appropriate solvents and brushes to remove deposits and dirt from all surfaces.

- Reassemble with Care: Follow the order you noted during disassembly. Ensure all seals and gaskets are properly positioned to prevent leaks.

- Adjust Settings: Calibrate the mixture and idle settings as specified for optimal performance.

Completing these steps will help ensure your engine runs smoothly and efficiently, prolonging its lifespan and enhancing its functionality.

Essential Safety Precautions

Ensuring safety while conducting maintenance on outdoor equipment is crucial. Proper precautions can prevent accidents and promote a secure working environment. Follow these guidelines to protect yourself and others during the process.

General Guidelines

- Always wear appropriate personal protective equipment, such as gloves and safety goggles.

- Ensure the workspace is well-lit and free of clutter.

- Keep a first aid kit accessible for emergencies.

Equipment Safety

- Disconnect the spark plug before beginning any work to prevent accidental starts.

- Use tools that are in good condition and appropriate for the task.

- Follow manufacturer guidelines for specific safety instructions related to your equipment.

When to Seek Professional Help

Determining the right moment to enlist the assistance of an expert can significantly impact the longevity and efficiency of your machinery. While some issues can be managed independently, others may require specialized knowledge and tools to ensure a proper resolution.

Here are some key indicators that it might be time to call in a professional:

- Persistent Problems: If the same issue keeps recurring despite your efforts, it may be a sign of a deeper problem.

- Lack of Knowledge: When you encounter unfamiliar symptoms or complex components that you don’t understand, seeking help is advisable.

- Safety Concerns: If you notice leaks, strange noises, or any potential hazards, it’s best to consult an expert to avoid accidents.

- Time Constraints: If you’re pressed for time or lack the resources to complete a repair efficiently, a professional can save you valuable time.

Ultimately, recognizing your limits and knowing when to seek expert guidance can prevent further complications and ensure that your equipment runs smoothly.