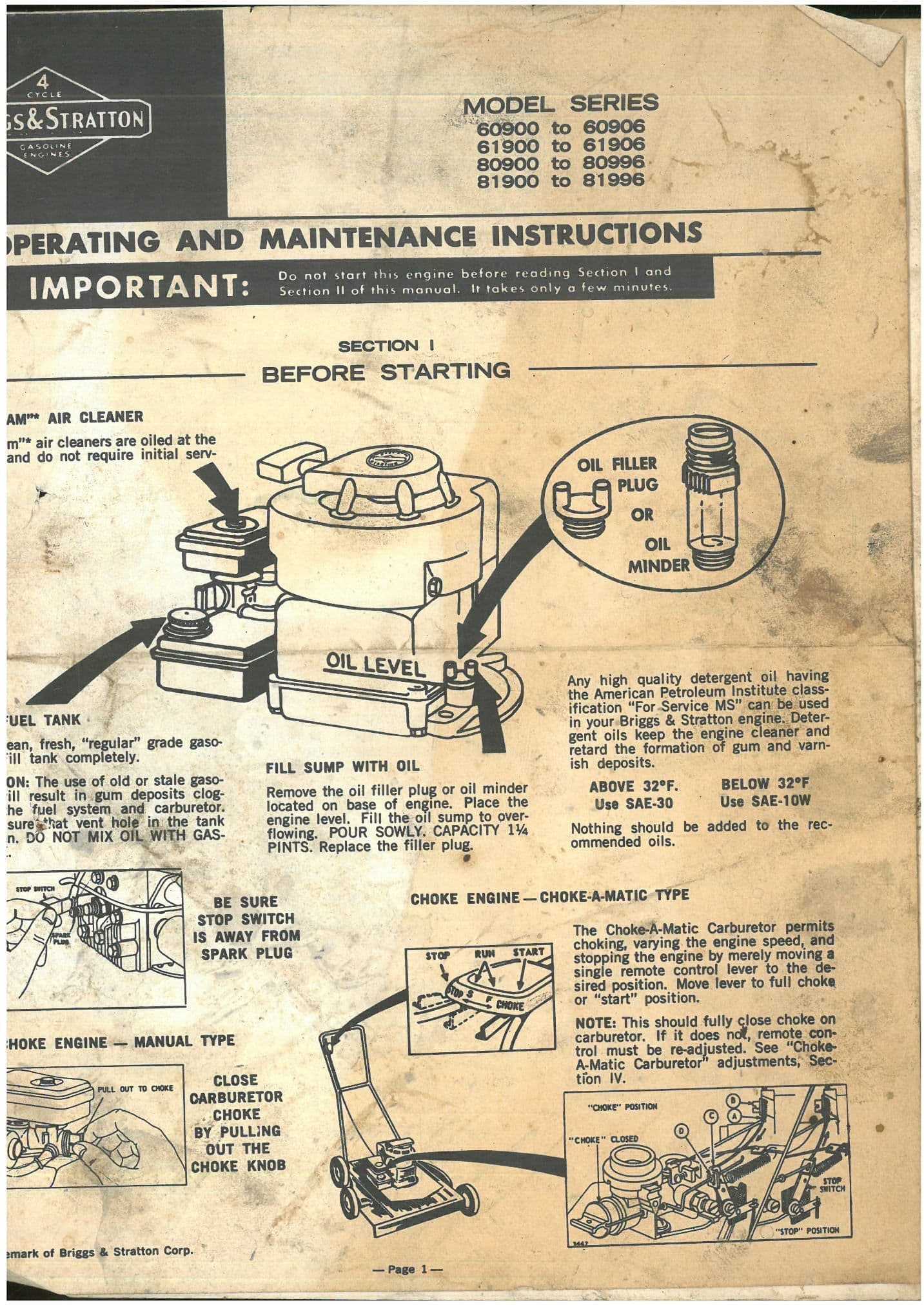

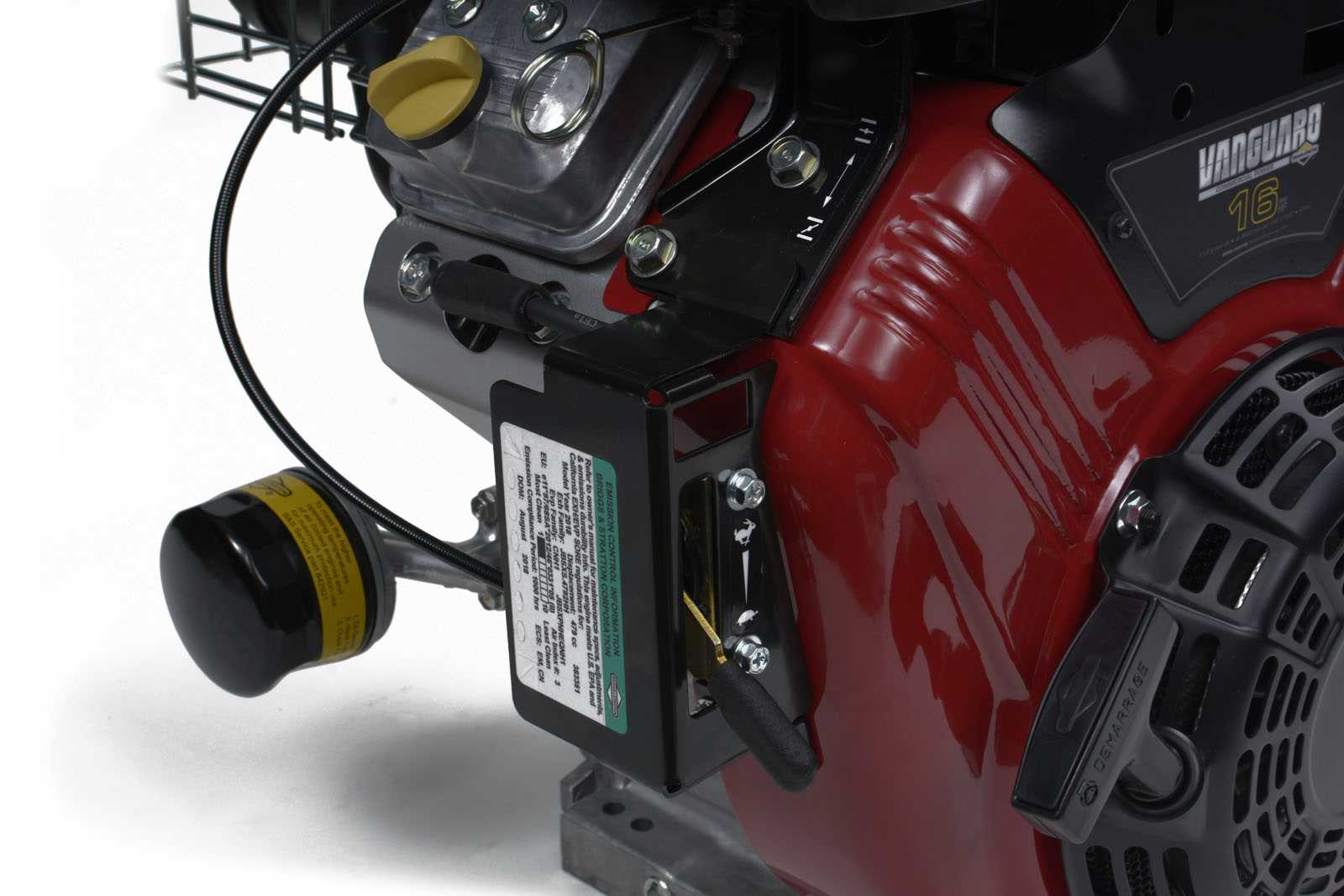

Understanding the intricacies of a high-powered 16 HP engine offers valuable insights for enthusiasts and mechanics alike. This powerful machine is a common choice for a range of demanding tasks, but like any complex system, it requires regular upkeep to perform at its best. By exploring each component in depth, users can ensure longevity and reliability in a wide range of applications.

In this guide, we cover essential maintenance practices, including troubleshooting techniques, common issues, and optimal servicing schedules. With step-by-step explanations, you’ll learn how to address issues, keep performance consistent, and reduce the risk of breakdowns. Each section is designed to enhance your understanding, giving you the confidence to handle various maintenance tasks efficiently.

Whether you’re a seasoned expert or a novice in engine care, these insights will equip you with the knowledge to extend the engine’s lifespan. Adopting these practices will not only boost performance but also ensure a smoother, more efficient operation. Dive into this guide to explore everything you need to keep a 16 HP engine running smoothly and effectively.

Essential Guide for Maintaining 16 HP Engines

Proper upkeep is key to ensuring long-lasting performance and reliability of 16 horsepower engines. By following core maintenance practices, users can keep their equipment in optimal condition, extend its lifespan, and prevent costly issues. This section provides foundational tips and step-by-step procedures to help you maintain your engine effectively.

1. Regular Inspections

- Check Oil Levels: Consistent oil checks are crucial. Low or dirty oil can lead to internal wear. Change oil according to recommended intervals for smooth operation.

- Examine Air Filters: Clogged or damaged filters reduce airflow, impacting engine efficiency. Clean or replace filters regularly to maintain peak performance.

- Inspect Spark Plugs: Worn or dirty spark plugs can cause misfiring. Replace them periodically to ensure smooth engine startup and consistent operation.

2. Seasonal Maintenance Tips

- Fuel System Care: During extended storage, drain the fuel system to prevent buildup. Add a stabilizer if fuel remains to avoid gum deposits.

- Battery Storage: Disconnect the battery when not in use for long periods, and store it in a cool, dry place to prolong battery life.

- Cooling System: Clean any debris around the cooling fins and fan to avoid overheating. Ensure ventilation paths are clear

Common Issues in 16 HP Motors

High-performance 16 HP engines, known for their robust output, occasionally experience recurring issues, particularly as they age or are subjected to heavy usage. These challenges can impact efficiency, fuel consumption, and overall functionality. Awareness of frequent symptoms can aid in early identification and proactive maintenance.

Overheating Challenges

One common issue is the tendency for certain motors to overheat, especially under prolonged operation or in high-temperature environments. Overheating can lead to premature wear, reduce the lifespan of engine parts, and necessitate additional cooling measures or part replacements.

Fuel System Complications

The fuel system in these engines may sometimes experience blockages, reduced flow, or other operational hindrances. Common culprits include sediment buildup or carburetor issues, which can disrupt the fuel supply and affect engine performance. Regular checks on the fuel components are crucial to ensure smooth operation.

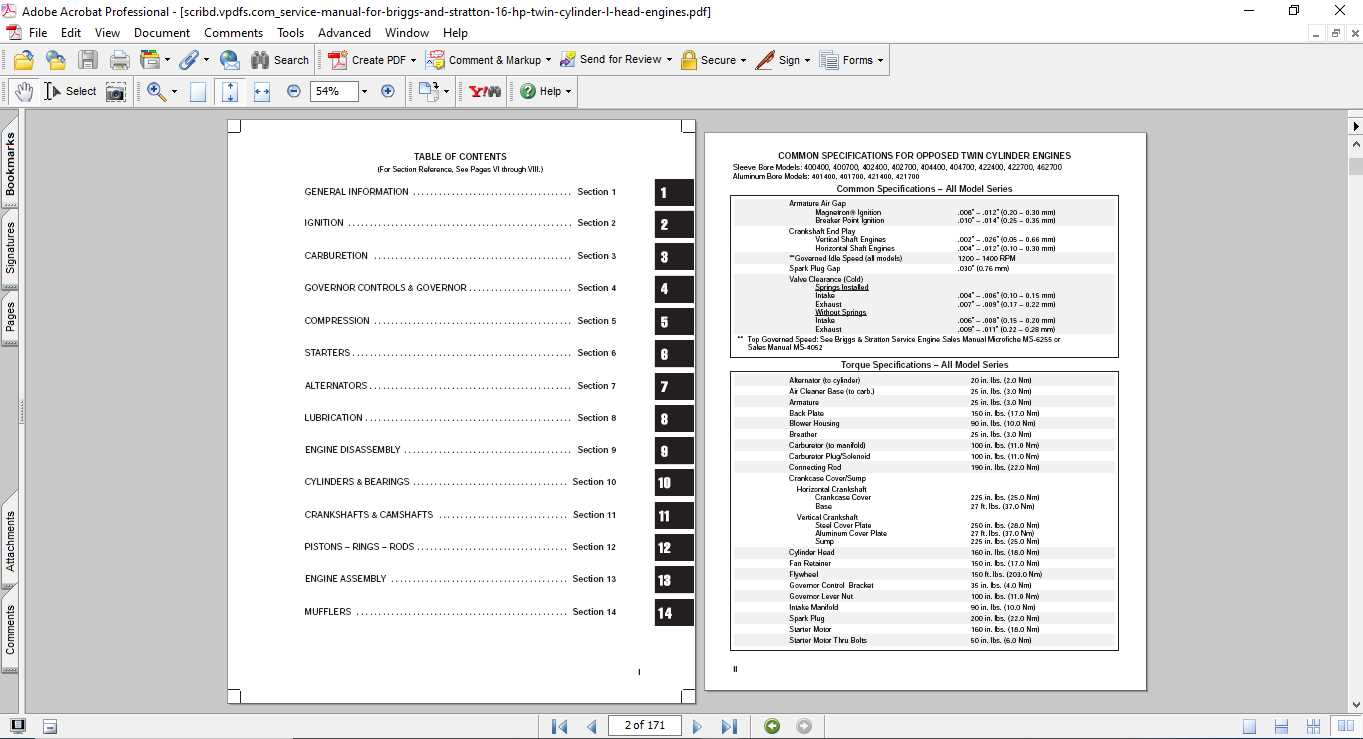

Issue Possible Cause Suggested Solution Overheating Poor air circulation or debris buildup Clean air filters, check cooling systems Starting Problems Weak spark plug or fuel line blockage Inspect spark plug, Step-by-Step Engine Tune-Up Procedures

Regular maintenance ensures the longevity and efficient performance of the engine. Following a structured approach to tuning the engine allows for optimal functionality and minimizes unexpected issues. The steps outlined here cover essential checks and adjustments for a thorough tune-up.

1. Inspecting and Replacing the Spark Plug

- Begin by carefully disconnecting the plug wire to avoid any unintentional starts.

- Use a wrench to remove the old plug, examining it for signs of wear, deposits, or damage.

- Replace with a new, properly gapped plug if necessary, ensuring a secure fit.

2. Cleaning or Replacing the Air Filter

- Remove the filter cover and check the filter for dust and debris build-up.

- If the filter appears clogged, consider either thoroughly cleaning it (if reusable) or replacing it.

- Reinstall securely to prevent contaminants from entering the system.

3. Adjusting Fuel and Oil Levels

- Check the fuel tank and top up as needed with fresh fuel.

- Inspect the oil level and quality, ensuring it meets recommended levels and replace if it

Key Components of the Ignition System

The ignition system is essential for initiating and sustaining the combustion process in the engine. This system includes various interconnected components that work together to generate the initial spark, ensuring smooth engine performance and reliability. Understanding these parts and their functions provides insight into maintaining efficient and consistent engine operation.

- Ignition Coil – This core component generates the high voltage necessary to produce a spark. It converts low battery voltage into a powerful spark, which ignites the air-fuel mixture within the engine.

- Spark Plug – Positioned within the cylinder, the spark plug receives the high voltage from the ignition coil and creates the spark needed to start combustion. Its condition greatly impacts engine efficiency.

- Flywheel – The flywheel stores rotational energy and, with its magnetic components, assists in generating an electrical charge. This component plays a crucial role in timing and helps maintain consistent power output.

- Ignition Switch – This switch activates the ignition process, allowing the engine to start or stop based on user input. It serves as the system’s primary control point.

- Battery – The battery supplies the initial electrical energy required to start the ignition process, powering other components within the system as well.

Lubrication Tips for Smooth Operation

Effective lubrication is essential for maintaining seamless functionality and longevity in your machine. Proper care ensures that each part moves without unnecessary friction, reducing wear and enhancing performance.

Key Areas to Lubricate

To optimize movement and prevent breakdowns, focus on the following areas where parts commonly experience the most stress and heat.

Part Recommended Lubricant Frequency of Application Cylinder Walls High-Temperature Oil Every 50 hours Crankshaft Grease Every 100 hours Bearings Multi-Purpose Grease Every 25 hours Checking Oil Levels

Monitoring oil levels regularly is crucial to prevent overheating and ensure smooth movement. Check levels before every use, and top up when needed, ensuring that the oil used is compatible with the machine’s specifications.

Troubleshooting Carburetor Problems

Identifying issues with the fuel mixing component can greatly enhance engine performance and efficiency. Common symptoms of malfunction can often be traced back to the improper functioning of this vital assembly, which regulates the air-fuel mixture necessary for combustion. This section will guide you through various signs of trouble and potential remedies.

Common Symptoms of Carburetor Issues

- Engine fails to start or is hard to start

- Unexpected stalling during operation

- Poor acceleration or power loss

- Excessive fuel consumption

- Rough idling or unusual noises

Steps for Diagnosing and Fixing Problems

- Examine fuel supply: Ensure there is adequate fuel and check for any blockages in the fuel line.

- Inspect for leaks: Look for any signs of fuel leakage around the carburetor and connections.

- Clean the component: Remove dirt and debris that may impede functionality. A thorough cleaning can resolve many issues.

- Adjust settings: Check the air-fuel mixture settings; improper adjustments can lead to performance problems.

- Replace worn parts: If components are damaged or excessively worn, consider replacing them for optimal performance.

Fuel System Maintenance and Repair

Proper upkeep of the fuel delivery system is essential for optimal performance and longevity of the engine. This section outlines key practices to ensure the fuel system operates efficiently, preventing common issues and enhancing overall functionality.

Regular attention to various components is vital. Here are some crucial aspects to consider:

- Fuel Filter Replacement: Changing the filter periodically helps eliminate contaminants that could affect engine performance.

- Fuel Line Inspection: Examine hoses for cracks, leaks, or signs of wear. Replace any damaged sections to prevent fuel loss.

- Carburetor Cleaning: Keeping the carburetor free from debris ensures proper fuel-air mixing, enhancing combustion efficiency.

- Check Fuel Quality: Use fresh fuel and avoid storing it for extended periods to prevent degradation and moisture accumulation.

- Inspect Fuel Pump: Ensure the fuel pump operates correctly, delivering the right amount of fuel to the engine.

By following these maintenance tips, you can extend the life of the fuel system and maintain optimal engine performance.

Replacing and Adjusting Spark Plugs

Maintaining optimal performance in small engines often involves the periodic replacement and adjustment of the ignition components. This crucial task ensures efficient combustion and enhances the overall functionality of the engine. Proper care of these elements can prevent misfires and improve fuel efficiency, making it an essential aspect of routine maintenance.

Importance of Spark Plug Maintenance

Regular upkeep of ignition components significantly impacts the engine’s reliability. Ignition devices should be inspected for wear and proper gap settings to guarantee smooth operation. A malfunctioning plug can lead to reduced power output and increased emissions, highlighting the necessity of timely interventions.

Steps for Replacement and Adjustment

Follow these steps to replace and adjust the ignition components effectively:

Step Description 1 Disconnect the spark plug wire to ensure safety before beginning the replacement. 2 Use a socket wrench to remove the old component, turning it counterclockwise. 3 Inspect the old plug for signs of damage or excessive wear, noting any irregularities. 4 Install the new component by hand to avoid cross-threading, then tighten it securely. 5 Adjust the gap according to the manufacturer’s specifications using a gap tool. 6 Reconnect the ignition wire and start the engine to verify proper functionality. Battery Care for Reliable Performance

Ensuring the longevity and efficiency of energy storage devices is crucial for optimal functionality of equipment. Proper maintenance not only enhances performance but also prevents unexpected failures. This section focuses on essential practices that promote the reliability of these power sources.

Regular Inspection

Conducting frequent checks on the energy storage unit can identify potential issues early. Look for signs of corrosion on terminals and ensure connections are secure. Visual inspections should be part of routine maintenance to prevent any disruptions in power delivery.

Optimal Charging Practices

Maintaining the correct charging levels is vital for maximizing the lifespan of energy storage devices. Avoid deep discharges and ensure the unit is fully charged after use. Utilizing a quality charger can help in achieving the ideal charge cycle, thereby enhancing overall efficiency.

Air Filter Cleaning and Replacement

Maintaining the cleanliness of the air filtration system is essential for the optimal performance of small engines. Regular attention to this component ensures that the engine receives adequate airflow, preventing issues related to dirt and debris buildup. Proper care can significantly enhance engine longevity and efficiency.

Cleaning the Air Filter

To begin the cleaning process, carefully remove the filter from its housing. Use a soft brush or compressed air to eliminate dust and particles. If the filter is heavily soiled, rinsing it with warm, soapy water can provide a more thorough clean. Ensure the filter is completely dry before reinserting it back into the engine.

When to Replace

Despite regular cleaning, there will be times when replacement is necessary. If the filter appears damaged, excessively dirty, or no longer fits securely in its housing, it’s time to replace it. Investing in a new filter is crucial for maintaining optimal airflow and preventing engine strain.

Regular maintenance of the air filtration system contributes to the overall health of your engine, ensuring reliable performance during use.

Cooling System Check-Up Guide

Maintaining an efficient temperature regulation mechanism is crucial for the longevity and performance of any power unit. Regular assessments ensure that components operate within optimal parameters, preventing overheating and subsequent damage. This section outlines essential steps for evaluating and maintaining the cooling system effectively.

Start by inspecting the coolant level and condition. Adequate fluid is vital for efficient heat dissipation, while contamination can hinder performance. Follow these steps to conduct a thorough examination:

Step Description 1 Check coolant level in the reservoir. Ensure it meets manufacturer specifications. 2 Examine the coolant for discoloration or debris, indicating potential contamination. 3 Inspect hoses and connections for leaks or wear, which could compromise the system’s integrity. 4 Test the radiator for blockages that may impede airflow and heat transfer. 5 Assess the fan operation to ensure proper airflow during the cooling cycle. After completing these checks, take the necessary actions to address any issues found. Regular maintenance of the temperature management system enhances performance and extends the lifespan of your equipment.

Essential Tools for Engine Repair

Having the right instruments is crucial for effectively working on engine systems. A well-equipped workshop can significantly streamline the process of diagnosing issues and performing maintenance tasks. Below are the fundamental tools every technician should have to ensure successful work on various types of power units.

Basic Hand Tools

- Wrenches: Adjustable and fixed sizes to fit different fasteners.

- Screwdrivers: A set including flathead and Phillips types.

- Pliers: Needle-nose and slip-joint varieties for gripping and twisting.

- Socket Set: Various sizes to accommodate different bolt heads.

Specialized Equipment

- Torque Wrench: Ensures fasteners are tightened to manufacturer specifications.

- Compression Tester: Helps assess the engine’s compression performance.

- Fuel Pressure Gauge: Monitors the pressure in the fuel delivery system.

- Multimeter: Measures voltage, current, and resistance for electrical diagnostics.

Long-Term Storage Preparation Tips

Ensuring that your equipment remains in optimal condition during extended periods of inactivity is crucial for longevity and performance. Proper preparation can prevent potential issues when it’s time to use the machine again. This section offers essential guidelines to facilitate safe and effective storage.

Essential Steps for Effective Storage

Before placing your equipment in long-term storage, follow these key steps:

Step Action 1 Clean the exterior and interior components thoroughly to remove dirt and debris. 2 Drain all fluids, including fuel and oil, to prevent deterioration and leakage. 3 Inspect the filters and replace them if necessary to maintain efficiency. 4 Store in a cool, dry location to avoid moisture buildup and rust formation. Additional Recommendations

Consider implementing the following additional practices for enhanced protection:

- Cover the equipment with a breathable fabric to shield it from dust.

- Check periodically for any signs of wear or damage during the storage period.

- Maintain a record of maintenance performed prior to storage for future reference.