Maintaining the efficiency and longevity of your carpet cleaning device is essential for achieving pristine results. Understanding the intricacies of your appliance empowers you to tackle common issues and perform essential upkeep with confidence. This section serves as a valuable resource for users seeking to enhance their cleaning experience through effective troubleshooting and care practices.

Throughout this guide, you will uncover essential information about components, operation techniques, and step-by-step procedures to address typical challenges that may arise. By familiarizing yourself with the specifics of your model, you can ensure optimal performance and extend the lifespan of your equipment.

Whether you are facing minor hiccups or seeking to optimize functionality, this comprehensive overview will provide you with the knowledge needed to navigate any obstacles. Embrace the opportunity to maintain your cleaner efficiently and enjoy the satisfaction of a job well done.

Understanding Bissell ProHeat 2X 9400

This section explores the functionality and key features of a popular cleaning appliance designed for effective carpet care. It provides insights into its operation, maintenance, and troubleshooting, making it easier for users to achieve optimal performance.

Key Features:

- Advanced cleaning technology for deep stain removal.

- Dual action brushes that enhance the cleaning process.

- Heatwave technology for maintaining optimal water temperature.

- Easy-to-fill tanks for hassle-free operation.

- Multiple cleaning modes for various surfaces.

Understanding the components:

- Water Tanks: Separate tanks for clean and dirty water ensure efficient cleaning.

- Brush System: Designed to reach deep into carpets, providing thorough dirt extraction.

- Control Panel: User-friendly interface for selecting cleaning modes and monitoring performance.

Maintenance Tips:

- Regularly check and clean the filters to ensure proper airflow.

- Inspect brushes for debris accumulation and clean as needed.

- Empty and rinse tanks after each use to prevent odors and buildup.

By understanding these aspects, users can enhance the longevity and effectiveness of their cleaning device, ensuring it remains a valuable tool for maintaining a spotless home.

Common Issues with the Bissell Model

When it comes to floor cleaning machines, users often encounter a variety of problems that can affect performance and efficiency. Understanding these common challenges can help in maintaining the equipment and ensuring it operates smoothly.

Frequent Problems

- Loss of Suction: One of the most reported issues is a noticeable decrease in suction power. This can stem from clogs in the hoses or filters.

- Water Leaks: Users may find that their unit leaks water during operation, often due to damaged seals or improperly connected hoses.

- Brush Roll Not Spinning: A malfunctioning brush roll can lead to ineffective cleaning. This issue is frequently caused by tangled hair or debris.

- Unusual Noises: Strange sounds while the machine is in use can indicate a problem, such as a jammed brush or worn-out components.

Maintenance Tips

- Regularly clean and inspect filters to prevent clogs.

- Check and replace seals if any leaks are detected.

- Remove any hair or debris from the brush roll after each use.

- Listen for unusual sounds and address them promptly to avoid further damage.

Essential Tools for Repairing Your Cleaner

When tackling issues with your cleaning appliance, having the right instruments at hand is crucial for efficient troubleshooting and maintenance. This guide outlines the fundamental implements that can help you achieve optimal performance and longevity for your device.

Screwdrivers are indispensable, especially those with interchangeable heads. A set that includes both flathead and Phillips types will cover most needs.

Wrenches are also essential for loosening or tightening various components. Adjustable wrenches can adapt to different sizes, making them versatile.

Another important tool is a multimeter. This device allows you to measure voltage, current, and resistance, aiding in diagnosing electrical issues effectively.

Cleaning brushes and compressed air cans are great for removing debris from hard-to-reach areas, ensuring that every nook and cranny stays functional.

Lastly, having replacement parts on hand can save time and frustration. Knowing where to source compatible components will ensure your appliance is back to its ultimate condition in no time.

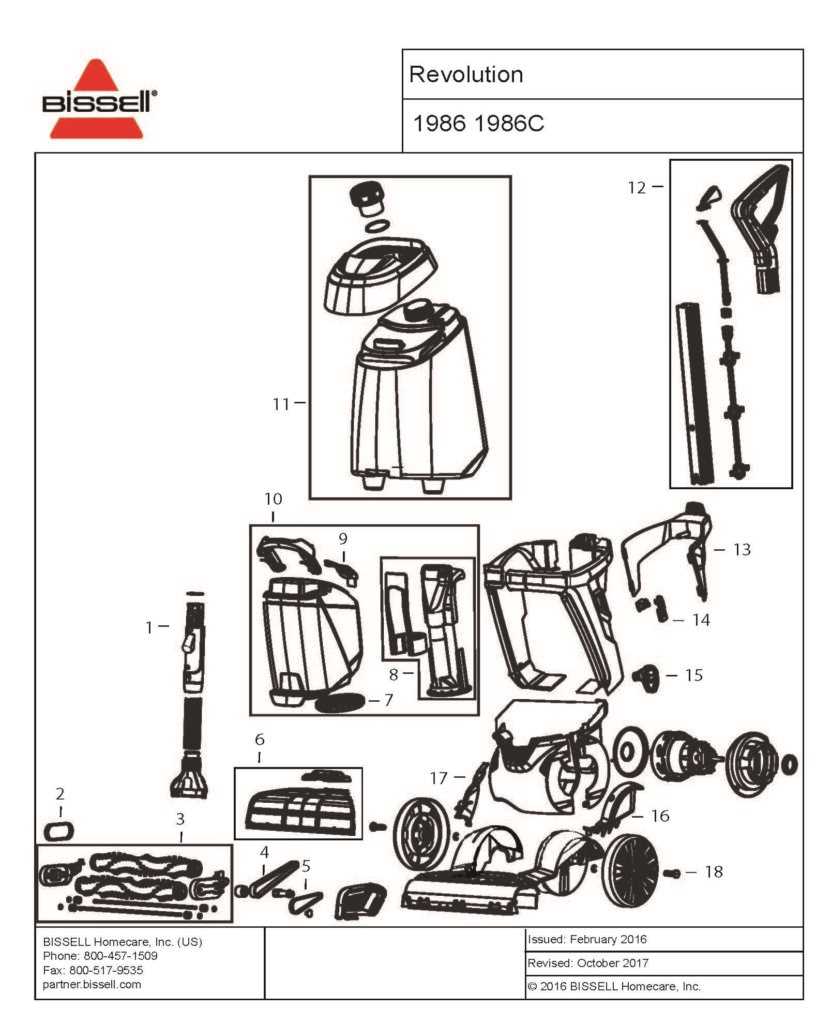

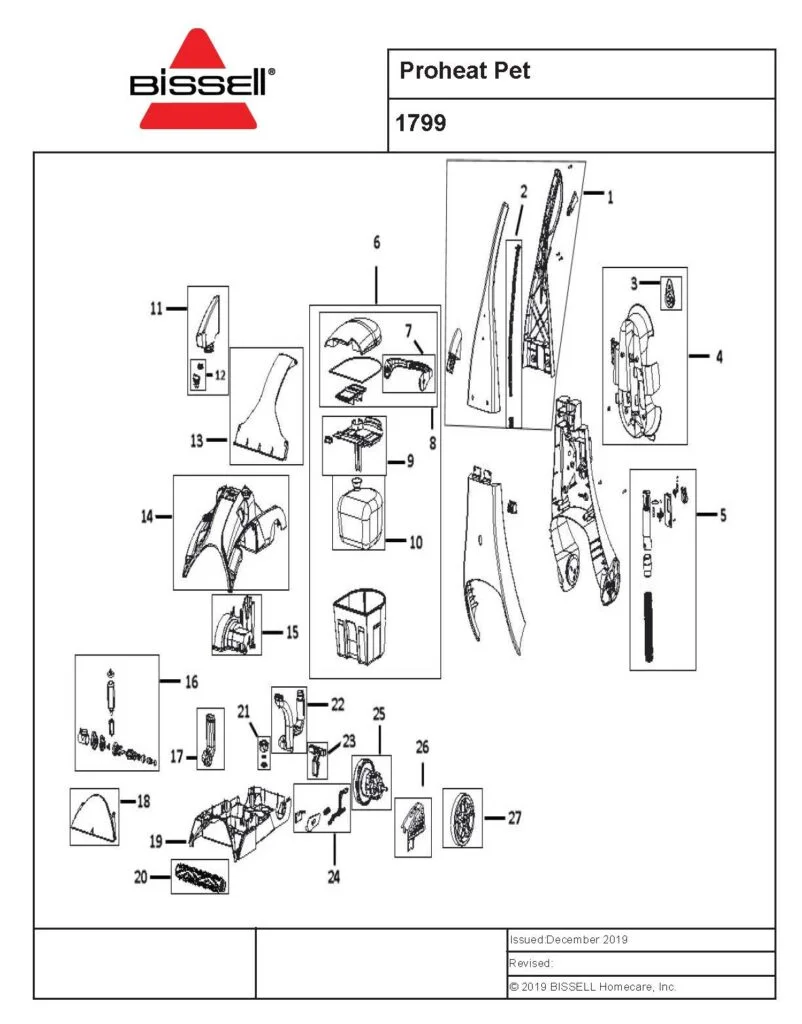

Step-by-Step Disassembly Guide

This section provides a comprehensive approach to dismantling your cleaning device safely and efficiently. By following these detailed instructions, you can gain access to internal components for maintenance or troubleshooting.

Step 1: Begin by ensuring the appliance is unplugged and cool. This is crucial for your safety. Locate all screws and fasteners on the exterior casing. Use a suitable screwdriver to remove them carefully, placing them in a container to avoid losing any parts.

Step 2: Once the screws are removed, gently pry apart the casing using a plastic tool to prevent damage. Work slowly around the edges, applying even pressure to release any clips holding the casing together.

Step 3: With the outer shell removed, take note of the internal components’ arrangement. Disconnect any wiring harnesses by carefully pulling them apart, ensuring you remember their original positions for reassembly.

Step 4: Next, identify the components you need to access, such as the motor or water tank. Remove any additional screws or clips securing these parts and take them out gently.

Step 5: After accessing the necessary components, inspect them for any signs of wear or damage. Document your findings for reference during the reassembly process.

Step 6: Once maintenance is complete, reverse the disassembly steps. Reconnect any wiring, secure all components in place, and reattach the outer casing carefully.

Following this structured approach will ensure a successful dismantling experience, leading to effective maintenance or troubleshooting of your cleaning device.

Replacing the Carpet Cleaning Solution Tank

When the time comes to change the cleaning solution tank in your machine, it’s essential to follow a systematic approach. This ensures efficient operation and maintains the quality of your cleaning process. This guide outlines the necessary steps to replace the solution tank effectively.

Tools and Materials Needed

- Replacement solution tank

- Screwdriver (if required)

- Clean cloth

- Bucket for excess solution

Step-by-Step Instructions

- Begin by unplugging the device to ensure safety during the process.

- Locate the solution tank on the machine. It is typically positioned at the rear or side.

- Remove any residual cleaning solution from the old tank by pouring it into a bucket.

- If necessary, detach the tank by unscrewing any fasteners holding it in place.

- Carefully lift the tank out, ensuring that no parts are damaged during removal.

- Take the new solution tank and insert it into the designated slot, making sure it fits securely.

- If screws were removed, reattach them to secure the new tank in place.

- Refill the new tank with the appropriate cleaning solution according to the manufacturer’s guidelines.

- Finally, plug the device back in and perform a test run to ensure proper installation.

By following these steps, you can ensure a smooth transition to a new solution tank, enhancing the overall performance of your cleaning device.

Fixing Motor and Suction Problems

Addressing issues with the engine and suction power is crucial for maintaining optimal performance of your cleaning appliance. Over time, various factors can lead to a decline in functionality, including blockages, wear, or electrical failures. Identifying and resolving these issues can enhance efficiency and prolong the lifespan of the device.

Common Symptoms

| Symptom | Possible Cause | Suggested Solution |

|---|---|---|

| Weak suction | Clogged hose or filters | Inspect and clean or replace filters; check for blockages in hoses. |

| Motor not running | Electrical issue or worn motor | Check power source; inspect wiring and consider motor replacement if necessary. |

| Unusual noises | Loose components or debris in motor | Tighten any loose parts and remove any foreign objects from the motor area. |

Troubleshooting Steps

To effectively troubleshoot the issues, start by disconnecting the unit from the power source. Check the filters and hoses for any obstructions and clean them thoroughly. Next, inspect the electrical connections for any signs of damage. If the motor remains unresponsive, it may be necessary to consult a professional for further assessment or replacement options.

Cleaning and Maintaining the Brushes

Regular upkeep of the cleaning apparatus is essential for optimal performance and longevity. The brushes play a crucial role in effective dirt removal and should be attended to frequently to ensure they remain in good working condition. Proper maintenance not only enhances cleaning efficiency but also prevents potential damage to the device.

Steps for Cleaning the Brushes

Follow these steps to keep the brushes in top shape:

| Step | Description |

|---|---|

| 1 | Unplug the device and remove any attachments. |

| 2 | Detach the brush assembly according to the manufacturer’s instructions. |

| 3 | Inspect the brushes for hair, lint, and debris accumulation. |

| 4 | Use scissors or a brush cleaning tool to remove tangled materials. |

| 5 | Wash the brushes with warm, soapy water and let them dry completely. |

| 6 | Reassemble the brush assembly and ensure it is securely attached. |

Tips for Maintenance

To prolong the lifespan of the brushes, consider these helpful tips:

- Clean the brushes after every few uses.

- Store the cleaning unit in a dry place to avoid mold growth.

- Regularly check for wear and tear, replacing brushes if necessary.

Diagnosing Electrical Failures

Identifying electrical malfunctions in cleaning equipment requires a systematic approach. Proper diagnostics can save time and resources by pinpointing the source of the issue effectively. Understanding the components involved and following a logical procedure can lead to successful troubleshooting.

Start by considering the following steps to diagnose electrical issues:

- Visual Inspection: Examine the device for any obvious signs of damage.

- Check Power Source: Ensure that the outlet is functioning properly by testing it with another device.

- Examine Cords and Connectors: Look for frayed wires or loose connections that could interrupt power flow.

After completing these initial checks, proceed with the following:

- Test the Switch: Use a multimeter to verify that the switch is operational.

- Inspect Internal Components: If accessible, check the circuit board and fuses for any signs of burn marks or breaks.

- Review User Manual: Refer to the user documentation for any specific diagnostic procedures or error codes.

By methodically working through these steps, one can effectively identify and address electrical failures, ensuring the equipment operates as intended.

Preventative Maintenance Tips for Longevity

Ensuring the longevity of your cleaning appliance requires a proactive approach to maintenance. Regular care not only enhances performance but also prevents costly repairs and extends the lifespan of the machine. By implementing a few simple practices, you can keep your device running smoothly for years to come.

Regularly Check and Clean Filters: Clogged filters can hinder performance and reduce efficiency. Inspect and clean or replace filters according to the manufacturer’s guidelines. This simple task can significantly improve airflow and cleaning effectiveness.

Inspect Hoses and Connections: Frequent examination of hoses and connections for leaks or blockages is essential. Address any issues promptly to prevent further damage and ensure optimal operation.

Keep the Machine Clean: After each use, wipe down the exterior and remove any debris from the brush and wheels. A clean appliance not only looks better but also functions more effectively.

Store Properly: When not in use, store the device in a dry, cool place. Avoid placing heavy objects on top of it, as this can cause structural damage over time.

Follow Usage Guidelines: Adhere to the manufacturer’s recommendations regarding usage and cleaning solutions. Using the wrong products can lead to damage and void warranties.

By following these preventative maintenance tips, you can enhance the durability and performance of your cleaning equipment, ensuring it remains a reliable tool in your home for many years.

When to Seek Professional Help

Recognizing when to call in an expert can be crucial for maintaining the longevity and functionality of your cleaning device. While many minor issues can be resolved through simple troubleshooting, there are certain signs that indicate the need for professional intervention.

Persistent Issues: If you notice that your appliance continues to exhibit problems despite following basic maintenance procedures, it’s time to consult a specialist. This could include unusual noises, leaks, or failure to operate correctly.

Electrical Problems: Any signs of electrical malfunctions, such as flickering lights or burnt smells, should be addressed immediately by a qualified technician. Attempting to fix these issues on your own can pose serious risks.

Complex Repairs: When confronted with mechanical or internal issues that require disassembly, seeking professional assistance is advisable. Specialized tools and expertise are often necessary for effective and safe repairs.

Warranty Concerns: If your device is still under warranty, attempting repairs yourself may void it. In such cases, reaching out to the manufacturer or an authorized service center is the best course of action.

In summary, while many minor issues can be handled independently, recognizing the limits of your capabilities and knowing when to involve a professional can save time, money, and prevent further damage to your equipment.

Frequently Asked Questions About Repairs

This section addresses common inquiries regarding maintenance and troubleshooting for your cleaning device. Here, we aim to provide clarity on typical issues users encounter, as well as practical solutions to enhance the longevity and effectiveness of your equipment.

What should I do if my appliance isn’t turning on? First, check the power source and ensure that the unit is properly plugged in. Inspect the power cord for any damage and reset any tripped circuit breakers. If the issue persists, consider consulting a professional.

Why is my machine not picking up dirt effectively? Reduced suction may be due to a clogged filter or full dirt tank. Regularly clean or replace filters and empty the tank to maintain optimal performance.

How can I fix leaks from my unit? Leaks can arise from loose or damaged hoses. Carefully inspect all connections and seals, tightening or replacing them as necessary to prevent fluid loss.

What maintenance is required to keep my cleaner in good condition? Routine cleaning of filters, brushes, and tanks is essential. Additionally, schedule regular inspections of the hoses and belts to identify wear and tear early.

Where can I find replacement parts? Replacement components can typically be sourced from authorized retailers, online marketplaces, or directly from manufacturers. Ensure you have the correct model information when searching for parts.