When it comes to ensuring the longevity and performance of your vehicle, having access to comprehensive information is crucial. This section serves as a valuable resource for enthusiasts and owners alike, providing insights into common issues and solutions that can arise over time. Understanding your automobile’s intricacies empowers you to address concerns proactively and maintain optimal functionality.

Whether you are tackling routine upkeep or facing unexpected challenges, a well-organized reference can make all the difference. From engine diagnostics to electrical systems, this guide covers a wide range of topics that are essential for anyone looking to enhance their knowledge and skills in automotive care. With detailed instructions and expert tips, you can navigate the complexities of your vehicle with confidence.

As you delve into this compilation of essential information, you’ll discover a wealth of practical advice tailored to meet the needs of various situations. Each section is designed to equip you with the tools necessary for successful intervention and maintenance, ensuring that your ride remains reliable and efficient for years to come.

Understanding the 2004 GMC Yukon

This section aims to provide insights into a full-size SUV that combines power, space, and versatility. Known for its robust performance and spacious interior, this vehicle is a favorite among families and adventurers alike. Its blend of comfort and capability makes it suitable for various driving conditions and lifestyles.

Key features of this model include advanced technology, safety options, and an impressive towing capacity, making it an excellent choice for both daily commutes and weekend getaways. Below is a summary of important specifications and attributes that highlight its appeal.

| Attribute | Details |

|---|---|

| Engine Options | V8 engines with varying horsepower |

| Seating Capacity | Up to 9 passengers |

| Towing Capacity | Up to 8,000 lbs |

| Fuel Economy | 15-20 MPG (combined) |

| Safety Features | Multiple airbags, ABS, stability control |

Understanding these attributes can greatly enhance the ownership experience, allowing drivers to make the most of their investment. The combination of utility and comfort in this SUV caters to a wide range of needs, making it a notable choice in its class.

Common Issues with GMC Yukon

Vehicles in this category often encounter a range of challenges over time, affecting performance and reliability. Understanding these typical problems can help owners anticipate maintenance needs and address issues promptly.

Frequent Mechanical Problems

- Transmission issues, such as slipping or hard shifting

- Engine performance concerns, including rough idling or stalling

- Braking system malfunctions, often indicated by unusual noises or reduced responsiveness

Electrical System Faults

- Battery drainage, commonly due to faulty wiring or parasitic draw

- Malfunctioning dashboard lights, which can lead to confusion about vehicle status

- Problems with the power windows and locks, frequently arising from motor failures

Essential Maintenance Tips for Owners

Regular upkeep is crucial for ensuring longevity and optimal performance of your vehicle. Adopting a proactive approach to maintenance can help you avoid costly repairs and enhance your driving experience. Below are key practices every vehicle owner should consider implementing.

| Maintenance Task | Frequency | Tips |

|---|---|---|

| Oil Change | Every 3,000 – 5,000 miles | Use high-quality oil and replace the filter with each change. |

| Tire Inspection | Monthly | Check for proper inflation and tread wear; rotate every 6,000 miles. |

| Brake System Check | Every 10,000 miles | Inspect pads and discs; listen for unusual noises. |

| Fluid Levels Check | Monthly | Monitor coolant, transmission, brake, and power steering fluids. |

| Battery Maintenance | Every 6 months | Check for corrosion and ensure connections are tight. |

By adhering to these essential practices, you can significantly extend the life of your vehicle and maintain its reliability on the road. Regular attention to these areas will ensure smooth operation and enhance safety for you and your passengers.

Step-by-Step Repair Procedures

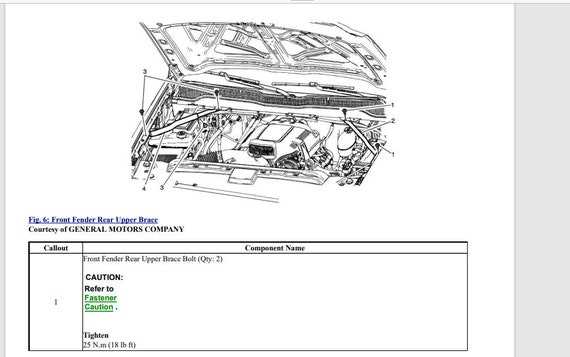

This section outlines a comprehensive guide to effectively address various issues that may arise in your vehicle. Following a structured approach not only ensures efficiency but also enhances the overall understanding of the maintenance process. Each step is designed to provide clarity and facilitate successful completion of tasks.

Preparation and Safety Measures

Before beginning any work, it is crucial to prepare the workspace and ensure safety. Gather all necessary tools and materials, and wear appropriate protective gear. Make sure the vehicle is parked on a level surface, and engage the parking brake to prevent any unintended movement.

Executing the Repair Process

Start by identifying the specific issue you are addressing. Refer to the vehicle’s documentation for detailed information on components and systems. Follow the outlined steps meticulously, and double-check each phase to confirm accuracy. If any complications arise, take a moment to reassess your approach and seek guidance if needed. Completing each task with attention to detail will lead to a more successful outcome.

Tools Required for DIY Repairs

When tackling automotive maintenance and restoration tasks on your own, having the right instruments is essential for efficiency and safety. Proper tools not only simplify the process but also enhance the quality of the work performed. Below is a comprehensive list of must-have equipment for enthusiasts aiming to handle various vehicle-related projects.

- Basic Hand Tools

- Wrenches (open-end and box-end)

- Sockets and ratchet set

- Various screwdrivers (flathead and Phillips)

- Pliers (needle-nose and standard)

- Torque wrench

- Specialized Tools

- OBD-II scanner for diagnostics

- Brake bleeder kit

- Oil filter wrench

- Ball joint separator

- Safety Equipment

- Safety goggles

- Mechanic gloves

- Dust masks

- Fire extinguisher

- Work Area Essentials

- Mechanic’s creeper for under-vehicle access

- Workbench with adequate lighting

- Tool chest for organization

- Jack and jack stands for vehicle elevation

Equipping yourself with these tools will prepare you for a wide range of tasks, ensuring that your automotive projects are executed effectively and safely. Regularly check and maintain your toolset to keep everything in optimal condition.

Engine Specifications and Troubleshooting

This section provides essential details regarding the powertrain’s characteristics and common issues encountered during operation. Understanding these specifications is crucial for effective maintenance and prompt diagnosis of potential problems. Accurate knowledge of engine parameters can aid in ensuring optimal performance and longevity.

Key Engine Specifications

| Specification | Value |

|---|---|

| Engine Type | V8 |

| Displacement | 5.3L |

| Horsepower | 295 hp |

| Torque | 335 lb-ft |

| Fuel System | Multi-Port Fuel Injection |

| Compression Ratio | 9.5:1 |

Troubleshooting Common Issues

Addressing engine-related concerns requires a systematic approach. Here are some frequent issues and their potential solutions:

- Rough Idle: Check for vacuum leaks and inspect spark plugs for wear.

- Decreased Power: Ensure air filters are clean and fuel injectors are functioning properly.

- Overheating: Examine the cooling system, including radiator and coolant levels.

- Unusual Noises: Identify any loose components or worn belts that may require replacement.

By following these guidelines and keeping engine specifications in mind, you can maintain optimal performance and tackle any issues that arise effectively.

Electrical System Diagnostics Guide

This section provides a comprehensive overview of troubleshooting techniques and methodologies for evaluating electrical systems in vehicles. Understanding the intricacies of these systems is essential for accurate diagnosis and efficient repairs. A systematic approach will help identify issues and streamline the problem-solving process.

1. Preliminary Checks: Begin by performing basic inspections. Verify that the battery connections are secure and free of corrosion. Check the fuses for any signs of damage or malfunction. These initial steps can often reveal obvious problems before delving deeper into diagnostics.

2. Utilizing Diagnostic Tools: Employ specialized equipment such as multimeters and oscilloscopes to measure voltage, current, and resistance. These tools are invaluable for assessing the functionality of various components within the electrical network.

3. Circuit Testing: Conduct thorough tests of individual circuits. Start by tracing the circuit from the power source to the component in question. Look for breaks, shorts, or any irregularities that could impede proper operation.

4. Component Analysis: Evaluate each electrical component systematically. Relays, switches, and sensors can often fail and require testing. Consult specifications to ensure each part operates within the manufacturer’s parameters.

5. Document Findings: Keep detailed records of all tests and observations. Documentation aids in tracking recurring issues and provides valuable information for future reference.

6. Conclusion: A methodical approach to electrical diagnostics not only enhances repair efficiency but also fosters a deeper understanding of the vehicle’s systems. Continuous learning and adaptation are key to mastering these skills.

Transmission Repair Techniques Explained

Understanding the nuances of transmission systems is essential for effective maintenance and restoration. A well-functioning transmission ensures seamless power delivery from the engine to the wheels, contributing to the overall performance of the vehicle. This section explores various methods used to diagnose and address transmission issues, enhancing both efficiency and longevity.

Common Symptoms of Transmission Problems

- Slipping gears or delayed engagement

- Unusual noises such as grinding or whining

- Fluid leaks beneath the vehicle

- Warning lights on the dashboard

Essential Techniques for Diagnosis

- Fluid Inspection: Checking the condition and level of transmission fluid is crucial. Discolored or burnt fluid indicates potential issues.

- Diagnostic Scanning: Utilizing a diagnostic scanner helps identify error codes that reveal underlying problems within the system.

- Road Test: A thorough test drive can uncover performance irregularities that may not be visible during stationary inspection.

By recognizing symptoms and employing effective diagnostic techniques, vehicle owners can make informed decisions regarding transmission care and repair.

Suspension and Steering Adjustments

The proper alignment and calibration of the suspension and steering systems are crucial for ensuring optimal vehicle performance and safety. These adjustments not only enhance ride comfort but also improve handling and extend the lifespan of various components.

Suspension adjustments involve aligning components to ensure even weight distribution and to minimize wear. This can include shock absorber settings, sway bar positioning, and spring tension calibrations. Regular checks help maintain balance and prevent premature wear on tires and suspension parts.

On the other hand, steering adjustments focus on ensuring that the steering system responds accurately and consistently. This may require evaluating tie rods, steering gear alignments, and the condition of power steering fluid. Proper steering setup is essential for precise control, particularly during cornering and abrupt maneuvers.

In conclusion, routine checks and adjustments of both suspension and steering systems play a vital role in maintaining a vehicle’s performance and safety. By addressing these areas proactively, drivers can enjoy a smoother ride and reduce the likelihood of future complications.

Brake System Maintenance Insights

Ensuring the optimal performance of your vehicle’s stopping mechanism is crucial for safety and longevity. Regular upkeep can prevent costly repairs and enhance overall driving experience. This section provides essential practices to maintain the braking system effectively.

Key Maintenance Practices

- Regular Inspection: Frequently check brake pads, rotors, and fluid levels to identify wear and tear early.

- Fluid Replacement: Brake fluid should be replaced according to manufacturer recommendations to prevent moisture buildup and maintain hydraulic efficiency.

- Pad and Rotor Replacement: Replace worn pads and damaged rotors to ensure effective stopping power.

Signs of Brake Issues

Awareness of warning signs can help catch problems before they escalate:

- Unusual Noises: Squeaking or grinding sounds often indicate worn pads or damaged components.

- Pulsating Pedal: A vibrating brake pedal may suggest warped rotors.

- Warning Lights: Dashboard indicators should not be ignored; they signal necessary maintenance.

By following these insights and addressing issues promptly, you can ensure a reliable and safe braking system for your vehicle.

Safety Features and Their Maintenance

Ensuring the functionality of safety components is essential for the well-being of both drivers and passengers. Regular attention to these elements not only enhances protection but also contributes to overall vehicle performance. Proper upkeep of safety features plays a crucial role in preventing accidents and minimizing risks on the road.

Key Safety Components

Among the most vital safety systems are airbags, anti-lock braking systems (ABS), and stability control mechanisms. Airbags should be inspected regularly to confirm that they are intact and functional, as any deployment issues can compromise their effectiveness during a collision. ABS helps maintain steering control during hard braking; ensuring that its sensors and hydraulic components are in good condition is critical. Additionally, stability control systems must be evaluated to guarantee they respond appropriately in adverse driving conditions.

Routine Maintenance Practices

Regular servicing is paramount for sustaining the efficacy of these features. Checking for software updates related to electronic safety systems can also enhance performance. Furthermore, replacing worn-out components, such as brake pads or sensors, is essential to prevent malfunctions. By adhering to a proactive maintenance schedule, vehicle owners can ensure that all safety systems operate at peak efficiency, providing peace of mind while on the road.

Upgrading Your GMC Yukon Components

Enhancing your vehicle’s functionality and performance can significantly elevate your driving experience. Whether you aim to improve efficiency, increase power, or simply update the aesthetics, there are numerous options to consider. Focusing on various components allows for a personalized touch and can lead to a more satisfying ride.

Performance Enhancements

One of the most popular ways to boost your vehicle’s capabilities is by upgrading the engine system. Cold air intakes can improve airflow, while high-performance exhaust systems enhance the engine’s efficiency. Additionally, upgrading to a more efficient fuel injector can lead to better fuel economy and increased horsepower.

Aesthetic and Comfort Improvements

For those seeking a more stylish appearance, consider investing in custom wheels and tires that not only enhance looks but also improve handling. Inside, upgrading the audio system can transform your driving experience. Replacing factory speakers with high-quality alternatives can provide a more immersive sound experience. Moreover, adding premium upholstery can elevate comfort levels significantly.