Ensuring your vehicle’s longevity and optimal performance requires a clear understanding of its key systems and components. This section provides essential insights into regular upkeep and detailed solutions for common issues, empowering owners with the knowledge needed to maintain their vehicle’s efficiency over the years.

Each part of the vehicle has its specific maintenance needs, and understanding these requirements can make a significant difference in overall

Comprehensive Guide for 2004 Nissan Titan Repairs

When handling maintenance and upkeep for a full-sized pickup, a well-rounded approach can ensure that every essential aspect of its operation is addressed effectively. This guide focuses on practical insights to help owners understand key components, typical issues, and necessary upkeep to keep performance at its peak.

Key Mechanical Systems

One of the primary areas to consider includes the engine and transmission. These systems play a vital role in the overall efficiency of the vehicle and require consistent inspection to detect any potential issues early. Regular oil changes, checking fluid levels, an

Understanding the 2004 Nissan Titan Engine

Exploring the heart of this powerful truck, the engine reveals essential details about its performance, durability, and construction. Designed to handle both heavy-duty tasks and smooth highway drives, this engine combines robustness with refined engineering. Its structure and components contribute to both its strength and efficiency, making it a reliable choice for a range of driving conditions.

The engine system incorporates various elements, including fuel management, air intake, and cooling processes, all working together to optimize power output. Understanding these components is key to maintaining peak performance, allowing drivers to achieve both longevity and reliability.

Beyond the basics, the design incorporates advanced features intended to reduce emissions while enhancing fuel economy. Familiarizing oneself with

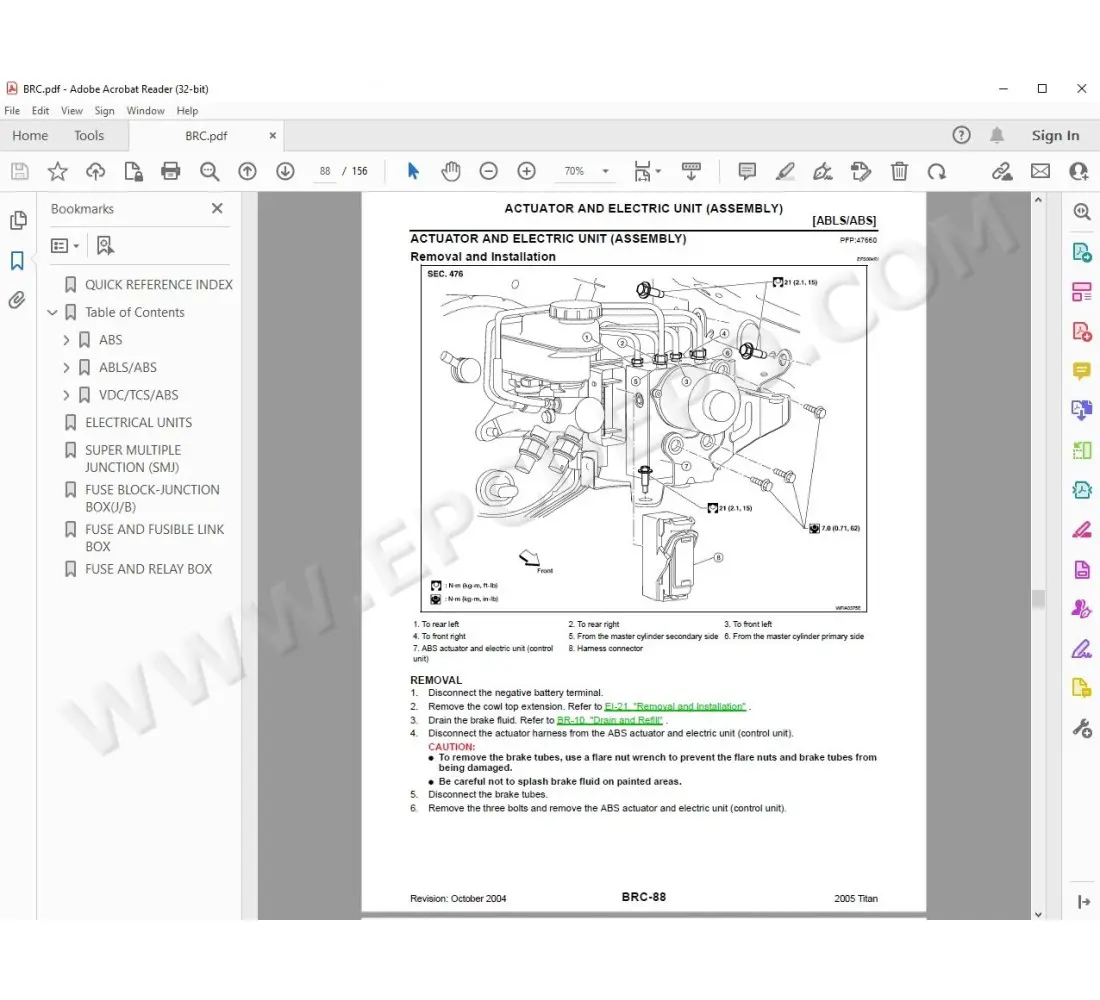

Step-by-Step Brake System Repairs

Maintaining the brake system is essential for ensuring vehicle safety and optimal performance on the road. This section provides a detailed guide on examining and servicing each component of the braking mechanism, from initial checks to the final adjustments, helping drivers keep their vehicles safe and functional.

Initial Inspection and Preparation

Start by preparing the necessary tools and equipment. Ensure the vehicle is parked on a flat surface, and secure it with wheel chocks. Lift the vehicle using a jack and support it with jack stands for stability. Before proceeding with the maintenance, examine each wheel area to identify visible wear or damage on the braking components.

- Inspect brake pads for thickness and uneven wear.

- Check brake rotors for warping or scoring.

- Examine brake lines and hoses for cracks or leaks.

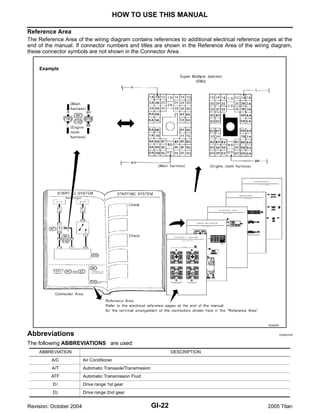

Inspecting and Maintaining Electrical Components

Regular inspection and upkeep of a vehicle’s electrical system is essential to ensure safety and reliability on the road. Electrical components control numerous functions, from lighting to essential engine operations, and must remain in optimal condition.

During inspections, it’s important to check connections, wiring, and terminals for signs of wear, corrosion, or loose connections. Any damaged wiring or exposed insulation can compromise the system’s effectiveness and should be repaired or replaced as needed.

Battery maintenance is another key aspect, as a clean and secure battery improves overall performance. Removing any buildup on terminals and ensuring tight connections can help prevent electrical issues. Periodic testing of fuses, switches, and relays is also recommended, as these small components play a crucial role in vehicle operation and safety.

By regularly inspecting and addressing issues in the electrical system, drivers

Essential Suspension Troubleshooting Tips

Understanding how to identify and address issues in a vehicle’s suspension system is crucial for maintaining a smooth, safe ride. A well-functioning suspension not only improves comfort but also ensures reliable handling and stability. This section provides practical insights for diagnosing common suspension concerns and highlights key areas to examine to help prevent more significant issues down the line.

Inspecting for Wear and Tear

Begin with a visual check of the suspension components, as worn or damaged parts often lead to noticeable symptoms such as unusual sounds or poor handling. Key components to examine include the shocks, struts, and bushings. Look for signs of leaks, cracks, or loose fittings. Regular inspection can help catch early signs of wear before they impact performance.

Assessing Steering and Alignment

A misaligned suspension can lead to handling issues and uneven tire wear. If the vehicle tends to drift to one side or if the steering feels unstable, a

Transmission Maintenance and Repair Procedures

The proper upkeep of a vehicle’s transmission system is crucial for ensuring smooth operation and longevity. This section outlines essential practices for maintaining and addressing issues that may arise within the transmission. Regular attention to this component can prevent more significant problems down the line.

Routine Inspection: Periodic checks of transmission fluid levels and quality are vital. Low or dirty fluid can lead to inadequate lubrication, causing wear and tear. It is recommended to examine the fluid for any signs of contamination, such as a burnt smell or discoloration.

Fluid Replacement: Changing the transmission fluid at recommended intervals is necessary for optimal performance. This process involves draining the old fluid, replacing the filter, and adding fresh fluid to the system. Following manufacturer specifications for fluid type is important for compatibility.

Sealing and Gasket Integrity: Ensuring that seals and gaskets are in good condition is essential to prevent leaks. Regular inspections can identify any wear or damage, allowing for timely replacements to avoid fluid loss and operational issues.

Diagnostic Procedures: In the event of transmission problems, utilizing diagnostic tools can help pinpoint issues. This may involve checking for error codes and conducting pressure tests to assess the health of the transmission system. Accurate diagnostics enable targeted solutions rather than broad, costly repairs.

Professional Assistance: While many maintenance tasks can be performed by vehicle owners, seeking professional help for complex issues is advisable. Skilled technicians possess the knowledge and tools necessary to address intricate problems effectively, ensuring the transmission operates reliably.

Common Fuel System Issues and Fixes

Fuel systems play a crucial role in the overall performance and efficiency of vehicles. Various complications can arise within this system, leading to suboptimal functionality. Understanding these common problems and their respective solutions can significantly enhance vehicle reliability and longevity.

One prevalent issue is fuel delivery failure, which can result from a clogged fuel filter. This blockage restricts the flow of fuel, causing the engine to run poorly or stall. Regularly replacing the fuel filter is a simple yet effective maintenance step to ensure consistent fuel flow.

Another common concern is fuel pump malfunction. A failing pump may lead to insufficient fuel pressure, resulting in poor acceleration and engine misfires. Listening for unusual noises from the pump can help identify problems early. If the pump is deemed faulty, replacing it promptly will restore optimal performance.

Additionally, fuel injector problems can lead to uneven fuel distribution. Symptoms may include rough idling or reduced fuel efficiency. Cleaning or replacing the injectors can resolve these issues, ensuring a smooth and efficient fuel delivery.

Lastly, issues with fuel lines, such as leaks or cracks, can severely impact the fuel system. Regular inspections for signs of wear and tear can help detect these problems early. Promptly addressing any leaks or damage is essential for maintaining safety and performance.

Cooling System Checks and Repairs

The efficiency of a vehicle’s cooling system is crucial for maintaining optimal engine performance. Regular inspections and timely maintenance can prevent overheating and other related issues. Understanding the components and their functions can help in diagnosing problems and implementing necessary solutions effectively.

Inspection of Components

Begin by examining the radiator, hoses, and thermostat for any signs of wear or damage. Look for leaks around connections and ensure that hoses are securely attached. Checking the coolant level is essential, as low fluid can lead to inadequate heat dissipation. If the coolant appears discolored or contaminated, it may be time for a replacement.

Performing Necessary Repairs

If issues are detected during inspection, addressing them promptly is vital. For minor leaks, applying a sealant may suffice, while more significant damage could require component replacement. Flushing the cooling system can eliminate accumulated debris and prevent clogs, ensuring proper fluid flow. Always refer to detailed guidelines for specific procedures to achieve effective repairs.

Interior Repairs and Component Replacement

This section focuses on addressing issues within the passenger compartment of a vehicle, emphasizing the importance of maintaining comfort and functionality. Ensuring that all internal elements are in optimal condition enhances both the driving experience and the overall aesthetic appeal.

Common tasks related to interior upkeep may include:

- Replacing worn-out upholstery and trim

- Repairing malfunctioning electronic components

- Fixing or upgrading the audio and entertainment systems

- Addressing issues with climate control features

- Restoring or replacing dashboard elements

For each repair or component exchange, following a systematic approach is crucial. Below are the general steps to consider:

- Assess the condition of the component or upholstery.

- Gather necessary tools and replacement parts.

- Carefully disassemble the affected area to access the component.

- Install the new or repaired item, ensuring proper fit and functionality.

- Reassemble the interior elements, testing for any operational issues.

Adhering to these guidelines will facilitate successful interior maintenance, contributing to a comfortable and enjoyable environment for all occupants.