Maintaining a vehicle is essential for ensuring its longevity and optimal performance. A thorough understanding of the components and systems within your automobile can significantly enhance your driving experience. This section will delve into the critical aspects of maintenance, offering insights into troubleshooting, parts replacement, and preventative care.

Whether you are a seasoned enthusiast or a novice, having access to detailed instructions and information can empower you to tackle various challenges that may arise. From routine checks to more complex procedures, a well-structured resource can guide you through the process with clarity and confidence. Here, we aim to equip you with the knowledge necessary to keep your vehicle in peak condition, ensuring safety and reliability on the road.

By exploring the nuances of upkeep and repair, you can develop a more profound appreciation for your automobile. The ability to address issues promptly not only saves time and money but also fosters a deeper connection with your vehicle. Join us as we navigate through essential topics that will enhance your understanding and proficiency in automotive care.

1998 Mazda B2500 Overview

This section provides a comprehensive examination of a popular compact truck known for its reliability and performance. It has garnered attention for its balanced combination of utility and comfort, making it a suitable choice for various driving needs.

Key Features

- Powerful engine options providing robust performance.

- Spacious cabin designed for comfort and functionality.

- Durable construction suitable for both urban and off-road conditions.

- Versatile cargo space catering to different hauling requirements.

Performance and Handling

This vehicle is engineered to deliver a smooth driving experience, with responsive handling and a well-tuned suspension system. It offers:

- Impressive towing capacity for various applications.

- Fuel efficiency that meets the needs of everyday driving.

- Stable performance in a variety of weather conditions.

Engine Specifications and Features

This section provides an overview of the key specifications and characteristics of the engine, highlighting its performance capabilities and technological innovations. Understanding these elements is essential for anyone looking to maintain or enhance their vehicle’s efficiency and reliability.

Performance Overview

The engine is designed to deliver a balance of power and fuel efficiency, making it suitable for a variety of driving conditions. Its robust construction ensures durability while maintaining optimal performance.

Technical Details

| Specification | Details |

|---|---|

| Cylinders | 4 |

| Displacement | 2.5 L |

| Horsepower | 143 hp |

| Torque | 165 lb-ft |

| Fuel System | Multi-Point Fuel Injection |

| Compression Ratio | 9.5:1 |

This information serves as a foundation for understanding the engine’s capabilities and provides essential data for effective maintenance and potential upgrades.

Common Issues and Troubleshooting

This section addresses frequent challenges that may arise with certain vehicle models, along with practical solutions. Understanding these common complications can significantly enhance the maintenance experience and promote effective resolution strategies.

Electrical System Failures

One prevalent concern involves the electrical system, which can manifest as issues with the battery, alternator, or wiring. Symptoms may include dimming headlights or difficulty starting the engine. Regularly inspecting battery connections and ensuring the alternator is functioning correctly can mitigate these problems. If electrical anomalies persist, it may be necessary to conduct a thorough examination of the wiring for any signs of wear or damage.

Engine Performance Issues

Another common issue relates to engine performance, which may present as reduced power, stalling, or unusual noises. Such symptoms can be linked to various factors, including fuel delivery problems or faulty ignition components. To address these concerns, checking the fuel filter and spark plugs is advisable. Keeping the engine well-maintained through regular servicing can also help prevent these complications from arising.

Maintenance Schedule and Recommendations

A well-structured maintenance routine is essential for the longevity and optimal performance of any vehicle. Adhering to a specific schedule can help prevent unexpected issues, ensuring reliable operation and enhancing safety. This section outlines the recommended intervals and practices to keep your vehicle in top shape.

Routine Maintenance Tasks

- Oil Change: Every 5,000 miles or 6 months, whichever comes first.

- Air Filter Replacement: Check every 12,000 miles; replace as needed.

- Tire Rotation: Rotate tires every 6,000 miles to promote even wear.

- Brake Inspection: Inspect brakes every 12,000 miles or if you notice unusual sounds.

- Fluid Checks: Regularly check coolant, brake fluid, transmission fluid, and power steering fluid levels.

Seasonal Checks

- Winter Preparation: Inspect battery, antifreeze levels, and windshield wipers before the cold months.

- Summer Readiness: Ensure air conditioning is functional and check tire pressure during warmer months.

Following this schedule and conducting regular checks will contribute significantly to the reliability and efficiency of your vehicle, helping you avoid costly repairs and ensuring a smooth driving experience.

Step-by-Step Repair Instructions

This section provides detailed guidance on resolving common issues related to vehicle maintenance and troubleshooting. Following these structured steps will ensure a systematic approach to effectively address various concerns that may arise during the lifespan of your automobile.

Preparation Steps

Before starting any work, gather all necessary tools and materials. Ensure that you have a clean workspace, as this will help prevent contamination and maintain organization throughout the process.

| Tools Needed | Description |

|---|---|

| Wrench Set | For loosening and tightening bolts. |

| Screwdriver Set | For various types of screws. |

| Jack and Stands | For safely lifting the vehicle. |

| Diagnostic Scanner | To read error codes from the vehicle’s computer. |

Procedure Overview

Start by diagnosing the problem using a scanner or visual inspection. Next, carefully disassemble the components involved, taking care to document each step. After completing the necessary repairs or replacements, reassemble the components and test the vehicle to ensure everything functions correctly.

Tools Required for Repairs

Proper maintenance and restoration of vehicles necessitate a specific set of instruments. Having the right equipment ensures efficient and effective handling of various tasks, minimizing the risk of errors and enhancing overall safety.

Essential Tools

- Wrenches: A variety of sizes, including metric and standard.

- Screwdrivers: Flathead and Phillips types for different fasteners.

- Pliers: Needle-nose and standard for gripping and cutting.

- Socket set: Ratchet and sockets for reaching tight spaces.

- Jack and jack stands: For safely lifting the vehicle.

Additional Equipment

- Torque wrench: Ensures bolts are tightened to the correct specifications.

- Diagnostic scanner: For identifying electronic issues.

- Oil catch pan: To manage fluids during maintenance.

- Work gloves: To protect hands during repairs.

- Flashlight: For improved visibility in low-light areas.

Electrical System Diagnostics

Effective assessment of the electrical system is crucial for maintaining optimal vehicle performance. Understanding the components and their functions allows for accurate troubleshooting and timely repairs, ensuring reliability on the road.

Key areas to focus on during diagnostics include:

- Battery Health: Check voltage levels and connections.

- Charging System: Evaluate the alternator and voltage regulator performance.

- Wiring Integrity: Inspect for frayed wires or loose connections that could cause shorts.

- Fuses: Identify blown fuses and investigate the underlying causes.

- Ground Connections: Ensure all ground points are secure and corrosion-free.

To perform a thorough evaluation, follow these steps:

- Start with a visual inspection of the electrical components.

- Use a multimeter to measure voltage and continuity.

- Check the functionality of key systems like lighting and ignition.

- Consult wiring diagrams to trace and isolate issues.

- Document findings and plan necessary repairs.

By adhering to these guidelines, one can effectively diagnose and rectify issues within the electrical system, enhancing both safety and performance.

Transmission Maintenance and Repair

Proper upkeep of the transmission system is crucial for ensuring optimal performance and longevity of your vehicle. Regular inspection and servicing can prevent costly failures and enhance the overall driving experience. This section outlines key practices and considerations for maintaining and troubleshooting the transmission.

Routine Maintenance Practices

Consistent maintenance tasks can significantly extend the lifespan of the transmission. Here are some essential activities to incorporate into your routine:

| Task | Frequency | Description |

|---|---|---|

| Fluid Check | Monthly | Inspect the transmission fluid level and condition; top off or replace if necessary. |

| Filter Replacement | Every 30,000 miles | Change the transmission filter to prevent debris buildup and ensure smooth operation. |

| Fluid Flush | Every 60,000 miles | Flush the transmission fluid to remove contaminants and refresh the system. |

Troubleshooting Common Issues

Recognizing early signs of transmission problems can save time and resources. Here are common indicators to watch for:

- Delayed engagement when shifting gears

- Unusual noises during operation

- Fluid leaks under the vehicle

If any of these symptoms arise, it is advisable to seek assistance promptly to avoid further damage to the transmission system.

Suspension and Steering Adjustments

Proper alignment and calibration of the suspension and steering systems are crucial for maintaining vehicle stability and handling. Ensuring these components function optimally can enhance ride quality and improve overall driving experience. Regular checks and adjustments can prevent excessive tire wear and prolong the lifespan of related parts.

Alignment Procedures

Alignment involves adjusting the angles of the wheels to the manufacturer’s specifications. This process helps ensure that the vehicle tracks straight and true, minimizing uneven tire wear. Common adjustments include camber, caster, and toe settings. It is essential to use precise tools to measure these angles accurately.

Suspension Component Inspection

Regular inspection of suspension elements such as shocks, struts, and bushings is vital. Worn or damaged components can lead to poor handling and a rough ride. Replacing these parts when necessary, along with proper adjustments, can significantly enhance performance. Additionally, lubricating moving parts helps maintain optimal functionality.

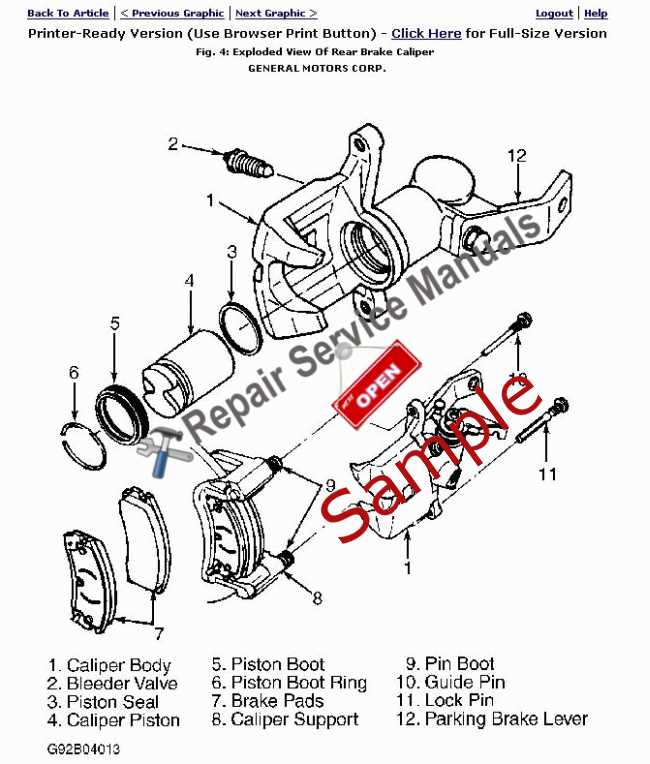

Brake System Inspection Techniques

Ensuring optimal performance of a vehicle’s braking mechanism is vital for safety and efficiency. Regular examination of the braking components can help identify potential issues before they escalate into serious problems. This section outlines essential practices for assessing the brake system effectively.

Start with a visual inspection of the entire braking assembly. Look for any signs of wear, damage, or corrosion on the calipers, rotors, and pads. Additionally, checking the brake fluid level and condition is crucial, as contaminated fluid can compromise braking effectiveness.

| Component | Inspection Technique | Common Issues |

|---|---|---|

| Brake Pads | Measure thickness; check for uneven wear | Worn pads, noise during braking |

| Brake Rotors | Check for warping and surface condition | Vibration, reduced contact area |

| Calipers | Examine for leaks and proper function | Fluid leaks, sticking calipers |

| Brake Lines | Inspect for cracks or signs of deterioration | Leaking fluid, reduced pressure |

| Brake Fluid | Check level and look for discoloration | Contamination, low levels |

After completing the visual checks, conduct a functional assessment by applying the brakes at various speeds. Listen for unusual sounds and note the responsiveness of the pedal. Address any irregularities immediately to maintain peak performance and safety.

Cooling System Maintenance Tips

Maintaining the cooling system is crucial for the optimal performance of any vehicle. Regular attention to this system can prevent overheating and ensure efficient engine operation. By following a few essential practices, you can prolong the lifespan of your vehicle’s components and enhance overall reliability.

Firstly, it is important to regularly check the coolant levels and top them up as necessary. A well-maintained fluid level ensures proper heat dissipation. Additionally, inspecting for leaks around hoses, the radiator, and the water pump can help identify issues before they escalate.

Flushing the cooling system at recommended intervals is another vital practice. This process removes debris and contaminants that may accumulate over time, improving the efficiency of heat transfer. Be sure to replace the coolant with a type specified by the manufacturer to avoid any chemical reactions that could damage the system.

Furthermore, examining the condition of the radiator cap is essential. A faulty cap can lead to pressure loss, resulting in overheating. Regularly inspect and replace any worn or damaged caps to maintain proper pressure within the system.

Finally, keep an eye on the thermostat’s performance. A malfunctioning thermostat can cause temperature fluctuations that may lead to severe engine damage. Regular checks can ensure that the thermostat operates smoothly and opens at the correct temperature.

Bodywork Repair and Replacement

Restoring the exterior of a vehicle is essential for maintaining its aesthetics and structural integrity. Whether addressing minor dents or extensive damage, proper techniques and tools are crucial for achieving a seamless finish. This section will explore the various methods for fixing and replacing body components effectively.

Assessment of damage is the first step in the process. Inspecting the affected areas helps determine whether repairs are feasible or if replacement is necessary. Minor dents can often be remedied using specialized tools, while larger issues may require new parts to ensure safety and performance.

When it comes to repair techniques, several options exist. For instance, pulling techniques can restore metal surfaces, while filler compounds can be utilized to smooth out imperfections. It’s vital to select the appropriate method based on the material and extent of the damage.

In cases where parts need to be replaced, sourcing high-quality components is key. OEM parts are often recommended to ensure compatibility and durability. Proper installation techniques must be followed to guarantee that new parts fit snugly and function correctly.

Finally, finishing touches play a significant role in achieving a polished look. Painting and clear coating should be done meticulously to match the original color and protect the surface from environmental factors. This attention to detail not only enhances the vehicle’s appearance but also contributes to its longevity.

Finding Quality Replacement Parts

When it comes to maintaining a vehicle, sourcing high-quality components is crucial for ensuring longevity and optimal performance. Reliable parts not only enhance the functionality of your vehicle but also contribute to safety on the road. This section explores effective strategies for locating superior replacement components, helping you make informed choices that benefit your driving experience.

Research and Reviews

Before making a purchase, it’s essential to conduct thorough research. Utilize online platforms to read reviews and gather feedback from other users. Look for reputable websites that specialize in automotive parts, as they often provide insights into product quality and durability. Engaging with forums and communities dedicated to vehicle maintenance can also yield valuable recommendations and experiences from fellow enthusiasts.

Manufacturer and Warranty Considerations

Always consider the manufacturer of the components you intend to buy. Established brands often stand behind their products with warranties, providing an extra layer of assurance regarding their quality. Choosing parts from well-known manufacturers can mitigate the risks associated with inferior alternatives. Moreover, verify if the components meet industry standards and specifications to ensure compatibility with your vehicle.