When it comes to outdoor upkeep, reliable tools are essential. A well-tuned lawn machine not only ensures a pristine yard but also provides a seamless experience, avoiding unexpected interruptions. Regular use, however, can lead to wear and tear, and understanding the nuances of upkeep can be the key to keeping it running smoothly season after season.

In this guide, we’ll explore practical solutions to common mechanical issues, maintenance practices, and preventive care that will keep your machine in peak condition. From diagnosing performance inconsistencies to understanding the essentials of care, we’ll walk through steps to troubleshoot effectively and boost longevity.

Whether you’re dealing with minor adjustments or looking to perform routine maintenance, following the right procedures can make all the difference. This resource will empower you to address typical challenges and keep your equipment performing as expected, ensuring that your lawn care remains efficient and enjoyable.

Honda Self Propelled Mower Repair Manual

Equipment maintenance is essential to ensure lasting performance and efficiency. A guide like this provides the necessary steps to keep yard tools in optimal working order, helping users handle common issues with ease. Addressing upkeep needs promptly prevents more complex problems from arising, promoting a smooth and reliable operation over time.

Basic Maintenance and Common Troubleshooting

Understanding the fundamentals of upkeep is critical for keeping outdoor equipment functional. Regularly cleaning the engine and checking components such as cables, blades, and wheels can help prevent malfunctions. When operational issues occur, reviewing these areas can often reveal simple solutions that extend the life of your equipment.

Adjustments and Replacements

Occasional adjustments or part replacements may be necessary as wear impacts performance. Tuning the engine, aligning drive components, or replacing worn blades restores functionality and efficiency. By following a structured approach to component care, users can achieve consistent results while maintaining safety and reliability.

Understanding Honda Mower Engine Basics

Engines powering outdoor lawn equipment rely on a combination of air, fuel, and ignition to operate efficiently. Proper maintenance and knowledge of engine components contribute significantly to consistent performance and longevity. This section explores fundamental aspects of these engines, focusing on how essential parts work together to power your equipment.

Key Components of the Engine

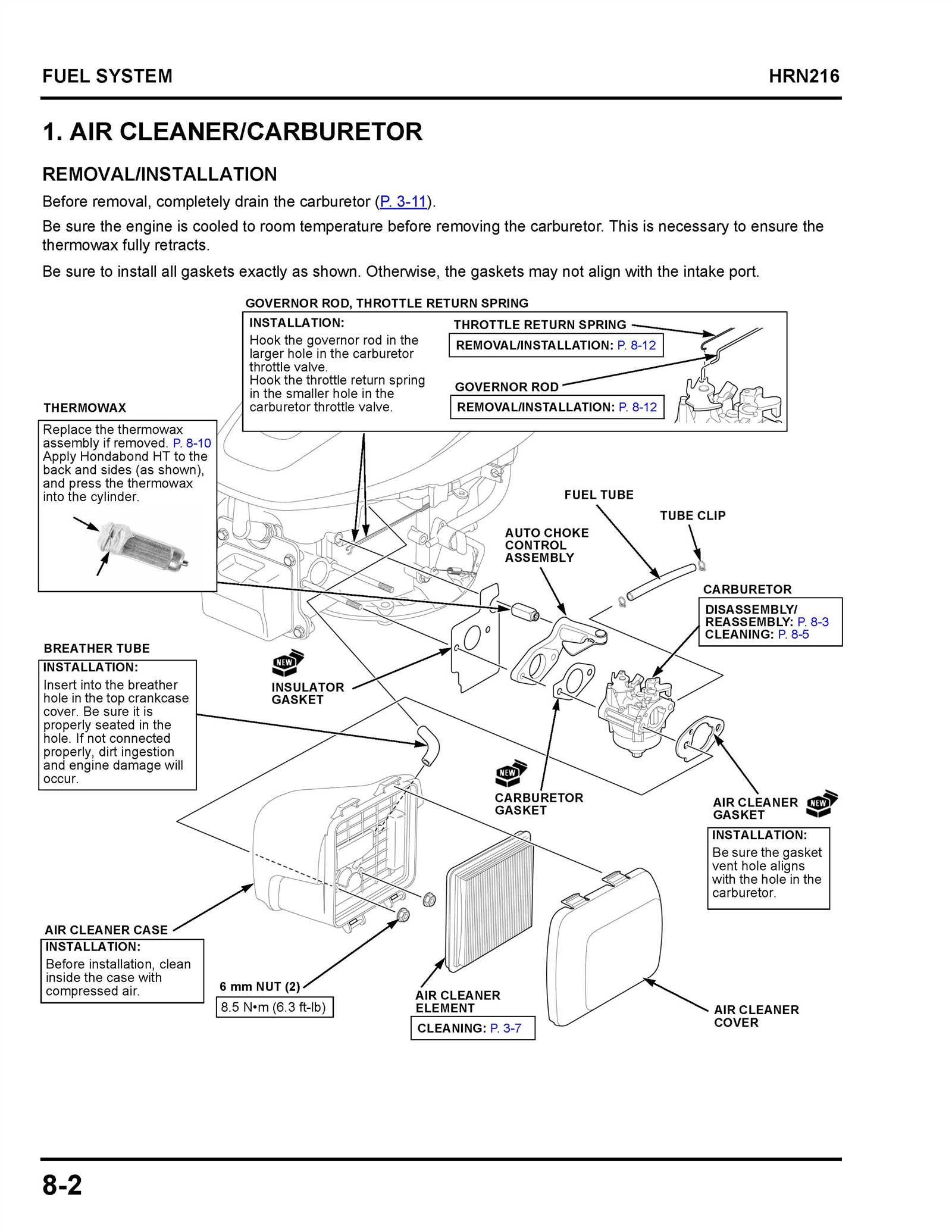

The engine typically comprises several critical parts, including the carburetor, spark plug, air filter, and fuel system. The carburetor manages the air-fuel mix, ensuring optimal combustion, while the spark plug ignites the mixture at the right moment. The air filter prevents debris from entering the system, and the fuel system supplies gasoline for combustion. Each of these components must be in good working order to sustain power output.

Importance of Proper Air and Fuel Mixture

A balanced air and fuel mixture is essential for smooth engine operation. The carburetor is primarily responsible for regulating this mix, adapting it based on engine speed and load. When the mixture is imbalanced–too rich or too lean–efficiency decreases, leading to potential performance issues. Regular carburetor cleaning and adjustment can prevent such problems, ensuring that the engine runs smoothly and reliably over time.

Diagnosing Drive System Issues

When a machine’s drive system encounters issues, it can affect performance and maneuverability. Identifying these problems early helps maintain smooth operation, and understanding common symptoms can simplify troubleshooting.

Below are steps to help pinpoint and address common drive-related concerns:

- Check the Drive Belt: Inspect the belt for signs of wear, fraying, or slippage. A worn-out belt can reduce power transmission, leading to sluggish movement or a complete stop.

- Examine the Transmission: Ensure the transmission is free from obstructions and in good condition. Grinding noises or inconsistent power may indicate internal issues requiring attention.

- Inspect the Drive Cable: Over time, cables can stretch or loosen, diminishing responsiveness. Adjusting or replacing a damaged cable often restores proper function.

- Lubricate Moving

How to Maintain Blade Sharpness

Keeping the blade in optimal condition is essential for efficient cutting and a healthy lawn. A sharp blade reduces the stress on the equipment and ensures a cleaner, more precise cut, which promotes grass health and minimizes tearing that can make lawns susceptible to disease.

Regular inspection is the first step in maintaining sharpness. Check the blade for signs of dullness, nicks, or uneven edges. If you notice any damage, it’s time for sharpening. Make sure the blade is removed carefully following safety protocols, and clean off any built-up grass or debris, as this can affect sharpening accuracy.

To sharpen, use a dedicated sharpening tool or a metal file, ensuring even strokes along the edge. Aim to maintain the original angle of the blade, as altering it can reduce efficiency. Always balance the blade after sharpening by ensuring each side is even, as an unbalanced blade can lead to vibration and wear on other parts.

Finally, reattach the blade securely, ensuring all bolts are tight. Regular sharpening not only extends the life of the blade but also enhances the performance of your equipment, resulting in a cleaner, healthier cut with each use.

Troubleshooting Mower Start-Up Problems

Getting your equipment to start reliably is essential for a smooth and efficient mowing experience. Start-up issues can stem from various sources, often related to fuel, spark, or airflow. By identifying the root cause, you can get your machine up and running without unnecessary delays.

Check the Fuel System

Begin by examining the fuel tank and lines. Old or stale fuel can lead to clogs in the fuel filter or carburetor, preventing the engine from starting. If fuel has been stored for an extended period, drain the tank and replace it with fresh fuel to ensure better ignition.Inspect the Spark Plug

The spark plug is critical for igniting fuel. A dirty or worn-out spark plug often results in poor combustion or no start at all. Remove the spark plug, clean it, and check for signs of damage. Replace it if necessary to restore reliable ignition.Ensure Proper Airflow

A blocked air filter can restrict airflow to the engine, impacting fuel combustion and hindering startup. Clean or repFixing Self-Propelled Speed Control

Addressing issues with speed adjustment mechanisms is essential for optimal performance. A properly functioning control allows the user to set the desired pace for efficient operation, ensuring that tasks are completed effectively.

Common problems can stem from wear and tear, misalignment, or mechanical failures within the system. Here’s a step-by-step guide to diagnosing and resolving speed control issues:

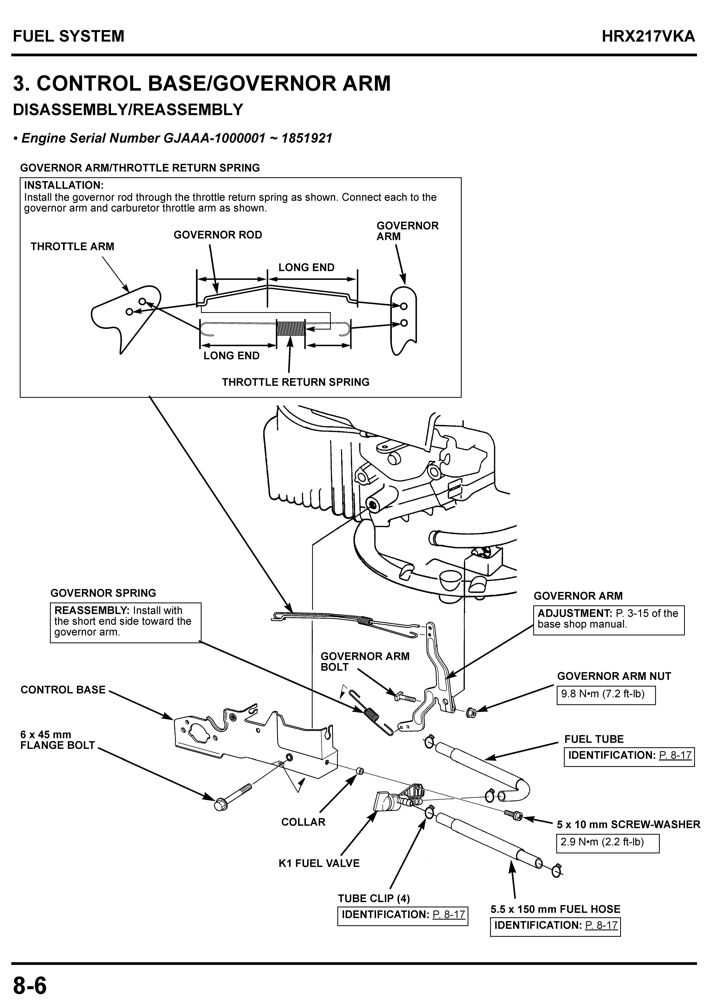

Issue Potential Causes Solutions Speed not adjustable Worn control cable, damaged throttle linkage Inspect and replace control cable, adjust or repair linkage Speed fluctuates Loose connections, debris in throttle Tighten connections, clean throttle components Speed too slow Engine power issues, blocked air filter Check engine performance, clean or replace air filter Speed too fast Incorrect adjustments, faulty governor Recalibrate settings, inspect and replace governor if needed Regular maintenance and prompt attention to issues can significantly enhance the longevity and efficiency of the equipment. Following these guidelines will help restore proper functionality to the speed control system.

Adjusting Cutting Height Mechanism

Proper adjustment of the cutting height is crucial for achieving an even and professional-looking finish on grass. This mechanism allows the operator to modify the blade’s position, ensuring that the desired grass length is maintained. Understanding how to make these adjustments can greatly enhance the performance of the equipment and the quality of the lawn.

Steps for Adjustment

To begin, locate the height adjustment lever or knob, usually situated near the wheels or on the handle. Depending on the model, this mechanism may operate differently, so consult the specific guidelines for your device. Typically, lifting or lowering the lever will either increase or decrease the blade’s height.

Checking the Height

After making the adjustments, it’s important to check the height to ensure it meets your preference. Measure the grass height using a ruler or similar tool. If necessary, repeat the adjustment process until the desired length is achieved. Regularly checking the cutting height will contribute to a healthier and more aesthetically pleasing lawn.

Cleaning and Replacing the Air Filter

Maintaining optimal engine performance requires regular attention to the air filter, which plays a crucial role in ensuring that clean air enters the combustion chamber. A clogged or dirty filter can lead to decreased efficiency, increased fuel consumption, and potential engine damage. This section outlines the steps to effectively clean and replace the air filter, ensuring the machine operates at peak efficiency.

Materials Needed

Item Description New Air Filter Replacement filter compatible with the specific model. Screwdriver To remove screws or fasteners holding the air filter cover. Cleaning Brush Soft brush for removing dirt and debris from the filter. Compressed Air For blowing out dirt from reusable filters, if applicable. Steps to Clean and Replace

Begin by ensuring the engine is off and cool. Locate the air filter cover, typically secured by screws. Use the screwdriver to remove the cover and take out the filter. If the filter is reusable, gently brush off dirt and debris or use compressed air to clean it. For disposable filters, replace it with a new one. Reattach the cover securely, ensuring a tight fit to prevent dirt ingress. Regular checks and maintenance of the air filter will significantly enhance the machine’s longevity and efficiency.

Inspecting and Replacing Spark Plugs

Regular examination and replacement of ignition components are essential for optimal engine performance. These parts play a crucial role in ensuring efficient combustion, which directly affects the overall functionality of the equipment. Understanding how to assess their condition and when to change them can significantly enhance operational efficiency and longevity.

Begin by disconnecting the spark plug wire to prevent accidental starting. Use a spark plug socket to carefully remove the old plug from the engine. Inspect it for signs of wear, such as discoloration or excessive carbon buildup. If the electrode is worn down or the insulator is cracked, it is time for a replacement.

Select a suitable replacement plug that matches the specifications of the equipment. Before installation, check the gap between the electrodes using a gap tool, adjusting it as necessary to ensure optimal performance. Screw in the new spark plug by hand initially, then tighten it with the socket, ensuring not to overtighten, which can damage the threads.

After securing the new plug, reconnect the ignition wire. Perform a test run to confirm that the engine starts smoothly and runs efficiently. Regular maintenance of this component will lead to improved performance and reliability.

Fuel System Care and Maintenance

Proper upkeep of the fuel system is essential for the optimal performance and longevity of your equipment. Regular maintenance ensures that the fuel flows efficiently and that the components remain in good condition, preventing potential issues that could arise from neglect.

Key areas to focus on include:

- Fuel Quality: Always use high-quality fuel that meets the manufacturer’s specifications. Avoid using stale or contaminated fuel, as it can lead to clogs and performance issues.

- Regular Inspection: Periodically check fuel lines, filters, and connections for any signs of wear or damage. Replace any worn components to maintain a safe and efficient system.

- Fuel Filter Replacement: Change the fuel filter at recommended intervals to prevent debris from entering the engine. A clean filter ensures smooth operation.

- Carburetor Maintenance: Keep the carburetor clean and free from deposits. Use a carburetor cleaner to remove any buildup that may affect fuel delivery.

- Stabilizers: If the equipment will be stored for an extended period, consider adding a fuel stabilizer to prevent degradation and separation of fuel components.

By adhering to these maintenance practices, you can enhance the reliability and efficiency of your machine, ensuring it operates at peak performance when needed.

Repairing Mower Transmission Problems

Issues with the power transfer mechanism can significantly hinder the functionality of your cutting machine. Understanding the common symptoms and underlying causes of these difficulties is crucial for effective troubleshooting and resolution. This section will guide you through identifying transmission-related concerns and provide insights into potential solutions.

Common Symptoms of Transmission Issues

When the power delivery system is malfunctioning, you may notice a variety of symptoms, including:

Symptom Description Sluggish Movement The equipment moves slower than expected or struggles to gain speed. Inability to Shift Gears Difficulty in changing speed settings or staying in gear. Unusual Noises Grinding or whining sounds when the machine is in operation. Fluid Leaks Visible fluid under the machine indicating potential seal or hose failures. Troubleshooting and Solutions

To address the issues mentioned, follow these troubleshooting steps:

- Inspect the belts and cables for wear or damage. Replace if necessary.

- Check for fluid levels in the transmission housing and top off if low.

- Examine for any leaks around seals and fittings, repairing or replacing as needed.

- Test the engagement of gears to ensure they shift smoothly without resistance.

By systematically addressing these areas, you can restore optimal performance and extend the lifespan of your equipment.

Common Belt Wear and Replacement

Wear and tear of belts in mechanical devices can lead to diminished performance and efficiency. Understanding the signs of degradation and knowing when to replace them is essential for maintaining optimal functionality. Regular inspection and timely action can prevent further damage and ensure smooth operation.

Signs of Belt Degradation

Various indicators signal that a belt may be nearing the end of its useful life. Recognizing these signs early can help avoid unexpected breakdowns.

Indicator Description Cracks or Fraying Visible damage on the belt surface can compromise its integrity. Squeaking Noises Unusual sounds during operation may suggest that the belt is slipping or misaligned. Slipping or Reduced Tension A decrease in tension can lead to ineffective power transmission. Replacement Procedure

When a belt shows signs of wear, replacing it promptly is crucial. The following steps outline the typical replacement process:

1. Disconnect the power source to ensure safety.

2. Remove any covers or guards that obstruct access to the belt.

3. Carefully detach the old belt from the pulleys, noting the configuration for reinstallation.

4. Install the new belt, ensuring it is aligned correctly with the pulleys.

5. Reassemble any removed components and reconnect the power source.

Following these guidelines will help maintain the performance of your equipment and extend its lifespan.

Winterizing Your Honda Mower Properly

Preparing your outdoor equipment for the colder months is essential to ensure its longevity and functionality. Properly protecting your device during winter helps prevent damage caused by freezing temperatures, moisture, and inactivity. This guide provides steps to effectively secure your tool for the off-season.

Cleaning and Maintenance

Start by thoroughly cleaning the equipment. Remove any grass clippings, dirt, and debris from the exterior. Use a brush or compressed air to clear out the undercarriage. Additionally, inspect the blades for wear and sharpen or replace them as necessary to ensure optimal performance when the growing season returns.

Fuel System Preparation

Next, focus on the fuel system. If using gasoline, add a fuel stabilizer to prevent degradation and ensure smooth operation in spring. Run the engine for a few minutes to circulate the treated fuel through the system. If storing for an extended period, consider draining the fuel tank completely to avoid any potential issues.

Final Steps: Cover the equipment with a breathable tarp or a dedicated cover to shield it from dust and moisture. Place it in a dry location, away from extreme temperature fluctuations. Following these steps will help maintain your equipment’s condition and readiness for the next season.