The intricacies of agricultural machinery demand a thorough understanding for effective upkeep and longevity. This resource is designed to provide essential insights into the best practices for maintaining and troubleshooting these powerful machines. Whether you are a seasoned operator or a newcomer, having access to detailed guidance can enhance your operational efficiency and minimize downtime.

Within this guide, you will find a wealth of information tailored to various aspects of machinery upkeep. From routine inspections to more complex adjustments, every section aims to empower users with the knowledge needed to tackle common issues. Emphasizing the importance of regular care, this resource will equip you with the skills necessary to ensure your equipment remains in optimal working condition.

Understanding the mechanisms behind these machines is crucial for anyone involved in agricultural activities. By familiarizing yourself with key components and their functions, you will be better prepared to address challenges that may arise. This guide serves as a valuable tool to navigate the nuances of maintenance, ensuring your equipment continues to perform at its best.

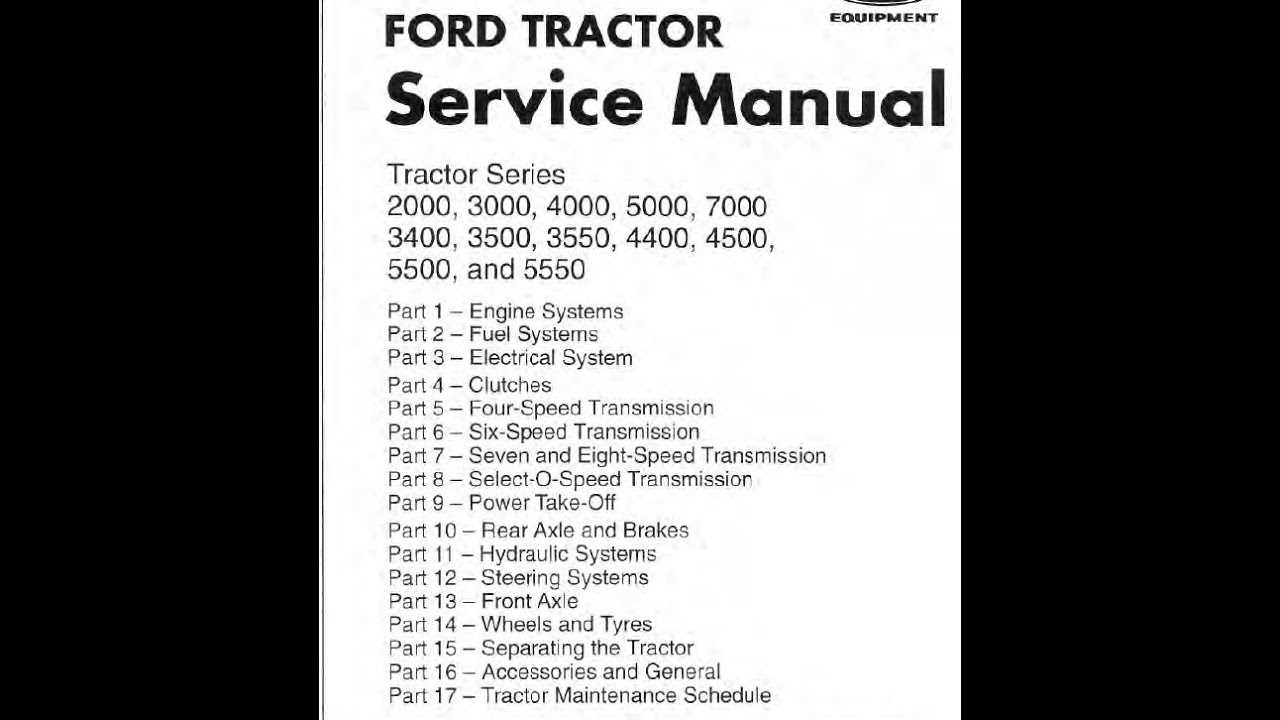

Overview of Ford 5000 Repair Manual

This section provides a comprehensive look at a guide designed for the maintenance and troubleshooting of a well-known agricultural vehicle. It serves as a vital resource for both novice and experienced operators, ensuring they can effectively manage routine tasks and address common issues that may arise during operation.

Key Features

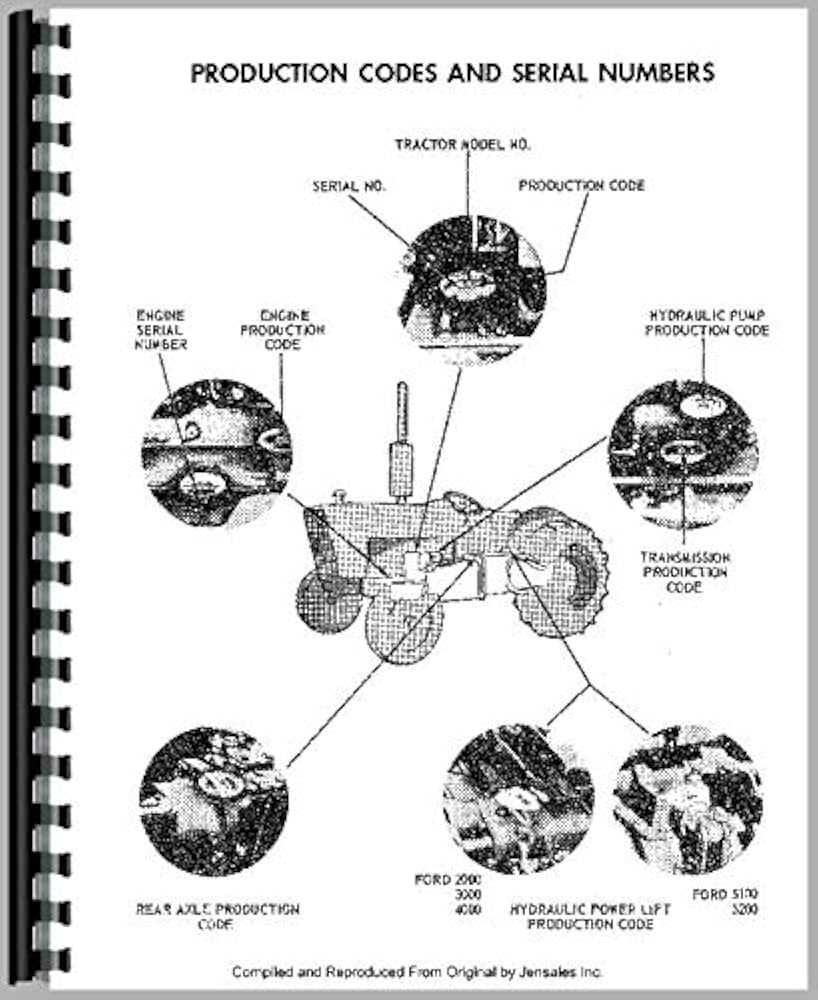

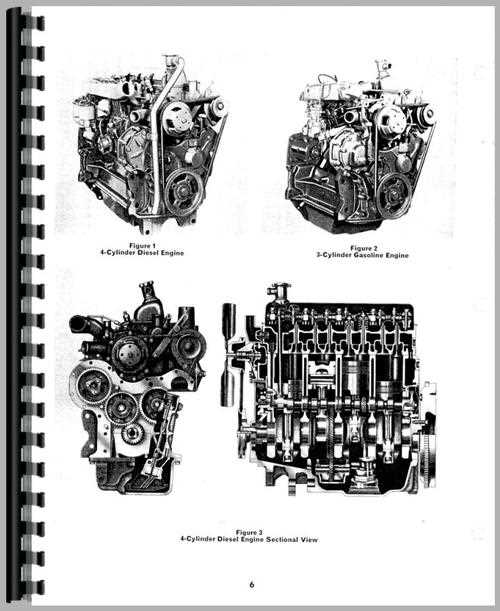

The guide includes detailed instructions on various systems, from the engine to the hydraulic components. Users will find step-by-step procedures for diagnostics, repair techniques, and preventive measures that enhance longevity and performance. Furthermore, it contains valuable illustrations that simplify complex tasks, making them accessible to all skill levels.

Importance of Maintenance

Regular upkeep is essential for maximizing the efficiency and reliability of any machinery. This resource emphasizes the significance of routine checks and timely interventions, which can prevent minor issues from escalating into major repairs. Adhering to the guidelines outlined ensures optimal functionality and can save considerable time and expenses in the long run.

Key Features of the Manual

This section explores the essential characteristics of the guide, which is designed to assist users in effectively maintaining and troubleshooting their machinery. Comprehensive instructions and detailed illustrations ensure that operators can confidently navigate repairs and upkeep tasks.

Detailed Instructions

The guide provides step-by-step procedures that simplify complex tasks, making them accessible to both novice and experienced users. Each section is organized logically, allowing for easy reference and quick access to vital information.

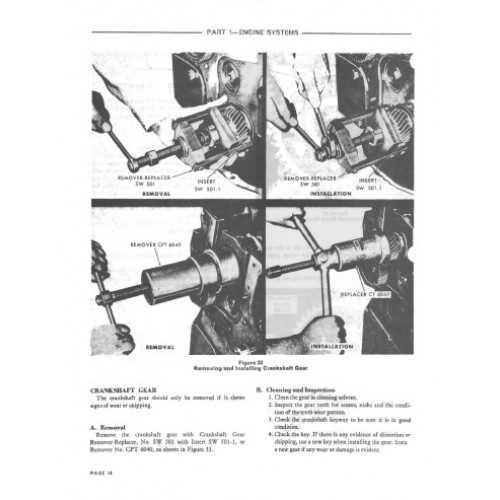

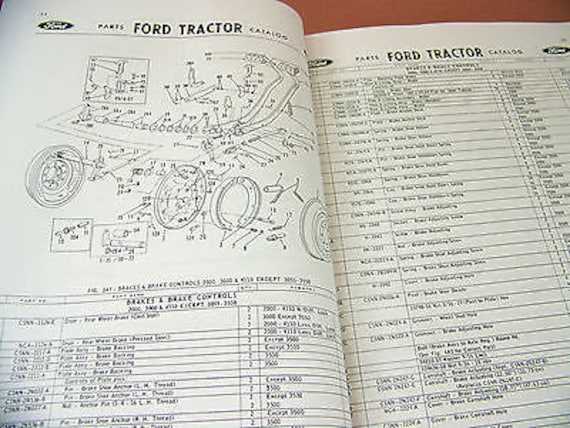

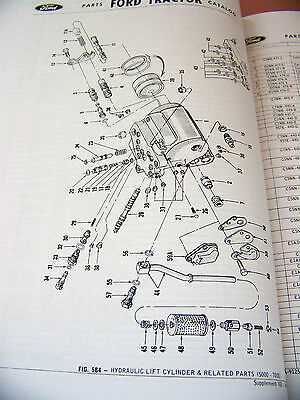

Illustrative Diagrams

Visual aids play a crucial role in the document, with diagrams and images enhancing the understanding of intricate components. Clear visuals help to clarify instructions, ensuring that users can identify parts and follow procedures accurately. This feature greatly reduces the likelihood of errors during maintenance.

Common Issues with Ford 5000

Understanding the frequent challenges faced by operators can significantly enhance the performance and longevity of these machines. By recognizing typical problems, users can implement timely interventions and maintain optimal functionality.

Engine Performance Problems

One of the most common concerns involves engine performance. Users may notice issues such as rough idling, lack of power, or excessive exhaust smoke. These symptoms can arise from various factors, including fuel delivery problems, air filter blockages, or ignition system failures.

Hydraulic System Failures

Another frequent issue is related to the hydraulic system. Operators might experience slow or unresponsive hydraulic functions, which can stem from fluid leaks, worn-out seals, or pump malfunctions. Regular maintenance and inspection can help mitigate these problems.

| Issue | Symptoms | Possible Causes |

|---|---|---|

| Engine Performance | Rough idling, power loss, smoke | Fuel delivery issues, air filter blockage, ignition failure |

| Hydraulic System | Slow operation, unresponsive controls | Fluid leaks, worn seals, pump issues |

Step-by-Step Troubleshooting Guide

This section provides a systematic approach to diagnosing issues that may arise with your equipment. By following a structured method, you can effectively identify problems and implement appropriate solutions. This guide will help you streamline the process and minimize downtime.

Begin by observing the symptoms of the malfunction. Take note of any unusual sounds, performance drops, or warning indicators. Document these observations as they will be crucial for accurate diagnosis.

Next, check the most common sources of issues, such as fluid levels, filters, and electrical connections. Ensure that all components are in good condition and properly secured. Regular maintenance practices can prevent many complications.

If the problem persists, consult the troubleshooting chart, which outlines specific issues and their potential causes. This resource can guide you toward pinpointing the exact malfunction and suggests corrective measures.

After isolating the issue, perform the necessary repairs or adjustments. Follow the manufacturer’s recommendations to ensure that all work is completed safely and effectively.

Finally, after resolving the issue, conduct a thorough test to confirm that the equipment is functioning correctly. Monitor performance closely for any recurring signs of trouble, as this may indicate underlying problems that require further attention.

Essential Tools for Repairs

Having the right equipment at hand is crucial for maintaining and restoring machinery effectively. A well-organized toolkit can significantly enhance the efficiency and quality of the work performed. Below, we explore the key instruments that are indispensable for any maintenance task.

Basic Hand Tools

Every technician should have a collection of fundamental hand tools. These are the building blocks for any job, enabling precise adjustments and thorough inspections.

| Tool | Purpose |

|---|---|

| Wrenches | Used for tightening or loosening nuts and bolts. |

| Screwdrivers | Essential for driving screws in various sizes and types. |

| Pliers | Ideal for gripping, twisting, and cutting wires. |

| Hammer | Used for driving nails or fitting parts together. |

Specialized Equipment

In addition to basic tools, certain specialized equipment can facilitate more complex tasks and ensure optimal performance of machinery.

| Equipment | Function |

|---|---|

| Torque Wrench | Ensures that fasteners are tightened to the correct specifications. |

| Diagnostic Tools | Helps identify issues through testing and data analysis. |

| Oil Filter Wrench | Facilitates easy removal of oil filters during maintenance. |

| Jack Stands | Provides support for elevated machinery, ensuring safety during repairs. |

Maintenance Tips for Longevity

Ensuring the extended lifespan of your machinery requires a proactive approach to upkeep and regular assessments. Implementing a systematic maintenance routine not only enhances performance but also reduces the likelihood of unexpected failures. By adhering to a few fundamental practices, you can significantly increase the durability and efficiency of your equipment.

First and foremost, regularly inspect all moving parts and systems. Look for signs of wear, corrosion, or loose connections. Timely identification of issues allows for prompt repairs, which can prevent more serious complications down the line. Additionally, keeping your machinery clean is crucial. Accumulated dirt and debris can lead to overheating and hinder performance, so make it a habit to clean both the exterior and interior components regularly.

Another essential aspect is fluid management. Regularly check and change oils, coolants, and other vital fluids to ensure optimal operation. Using high-quality lubricants will minimize friction and reduce wear on critical components. Furthermore, adhere to the manufacturer’s guidelines for service intervals to maintain the integrity of the machinery.

Lastly, maintain a detailed service log. Documenting all maintenance activities, repairs, and replacements will provide a valuable reference for future servicing. This practice not only helps track performance trends but also assists in identifying recurring issues, allowing for more effective solutions. By following these tips, you can enhance the longevity and reliability of your equipment, ensuring it remains a dependable asset for years to come.

Electrical System Diagnostics

The functionality of a vehicle’s electrical framework is crucial for its overall performance. Troubleshooting this system involves a systematic approach to identify and rectify issues that may hinder proper operation. Understanding the various components and their interconnections is essential for effective diagnosis and resolution.

Common Electrical Issues

Several problems can arise within the electrical system, including faulty wiring, malfunctioning switches, and battery failures. Symptoms such as dimming lights, difficulty starting the engine, or erratic gauge readings often indicate underlying electrical faults. Employing a methodical diagnostic process can help pinpoint the source of these issues.

Diagnostic Tools and Techniques

Utilizing appropriate tools, such as multimeters and circuit testers, is vital for evaluating the integrity of electrical circuits. Visual inspections can also reveal signs of wear or damage. Testing components in isolation allows for a clearer understanding of their functionality. Maintaining a thorough documentation of findings aids in tracking recurring problems and ensuring a comprehensive approach to repairs.

Engine Overhaul Procedures Explained

Overhauling an engine is a comprehensive process aimed at restoring it to optimal performance. This involves a series of meticulous steps designed to address wear and tear, enhance efficiency, and extend the lifespan of the power unit. Understanding these procedures is crucial for anyone looking to undertake such a project, ensuring that each stage is executed with precision and care.

Key Steps in the Overhaul Process

- Disassembly: Carefully remove components to access the internal structure without causing damage.

- Inspection: Examine parts for signs of wear, corrosion, or other issues that may affect performance.

- Cleaning: Thoroughly clean all components to eliminate dirt, oil, and debris.

- Replacement: Identify and replace any worn or damaged parts with new or refurbished components.

- Reassembly: Reassemble the engine following the correct order and specifications.

- Testing: Conduct tests to ensure proper functioning and performance of the engine.

Essential Tools and Equipment

- Socket Set: For loosening and tightening bolts and nuts.

- Torque Wrench: To ensure components are secured to the correct specifications.

- Engine Hoist: For safely lifting and handling the engine.

- Cleaning Supplies: Including solvents and brushes for thorough cleaning.

- Inspection Tools: Such as calipers and micrometers for precise measurements.

By adhering to these outlined procedures, individuals can effectively carry out an overhaul, ensuring enhanced performance and reliability of the engine. Proper planning and execution at each stage are vital for a successful outcome.

Hydraulic System Maintenance Techniques

Maintaining the hydraulic system is crucial for ensuring optimal performance and longevity of machinery. Regular attention to this component can prevent breakdowns and enhance operational efficiency. This section outlines effective practices to keep hydraulic systems in peak condition, emphasizing routine checks, fluid management, and component care.

Routine Inspections

Conducting frequent inspections of the hydraulic system is essential. Look for leaks, wear, and signs of damage in hoses, fittings, and connections. Ensuring that all components are securely fastened can prevent potential failures. Regularly check the fluid levels and quality, as contaminants can significantly impact system performance.

Fluid Management

Proper fluid management is vital for hydraulic systems. Use the recommended fluid type and maintain it at the appropriate levels. Replace fluids according to the manufacturer’s guidelines to avoid degradation. Implement a filtration system to remove impurities and monitor the condition of the fluid regularly to ensure it remains effective.

Transmission and Gearbox Insights

Understanding the intricacies of the transmission and gearbox is crucial for ensuring optimal performance and longevity of machinery. These components play a vital role in the overall functionality, converting engine power into usable torque and facilitating smooth operation across various speeds and loads.

Types of Transmission Systems

There are primarily two types of transmission systems: manual and automatic. Each system offers distinct advantages and is suited to different operational needs.

| Type | Advantages | Considerations |

|---|---|---|

| Manual | Greater control, potentially better fuel efficiency | Requires driver skill, can be less convenient in traffic |

| Automatic | Ease of use, smooth shifting | Higher maintenance costs, may reduce driver engagement |

Common Issues and Maintenance Tips

Regular inspection and maintenance are key to preventing common issues such as slipping gears or fluid leaks. Ensure that the transmission fluid is at the proper level and changed as recommended. Additionally, pay attention to unusual noises or vibrations, which can indicate underlying problems.

Bodywork and Frame Repair Tips

Maintaining the exterior and structure of your vehicle is crucial for both aesthetics and functionality. Addressing issues with the body and frame can enhance longevity and safety, ensuring that the vehicle remains in optimal condition. This section provides essential guidance for tackling common challenges in these areas.

Assessing Damage: Before undertaking any work, it is vital to thoroughly inspect the affected areas. Look for dents, scratches, or signs of rust. A comprehensive evaluation will help you determine the extent of the damage and the necessary steps to take.

Preparing the Surface: Proper preparation is key to achieving a professional finish. Clean the area with soap and water, then dry it completely. For deeper scratches or rust spots, use sandpaper or a wire brush to remove debris and ensure a smooth surface for treatment.

Choosing the Right Materials: Select high-quality products suitable for your vehicle’s specific needs. Whether you’re using filler for dents or primer for painting, the right materials can significantly impact the final outcome. Always follow manufacturer instructions for best results.

Painting Techniques: When repainting, consider applying multiple thin coats instead of one thick layer. This method allows for better adhesion and reduces the risk of drips or uneven finishes. Allow each coat to dry completely before applying the next.

Frame Integrity: Inspect the frame for any signs of bending or damage. If any issues are found, it may be necessary to utilize a frame straightening tool or consult a professional for more complex repairs. Maintaining the structural integrity is essential for the overall safety of the vehicle.

Regular Maintenance: To prevent future issues, conduct routine checks on both the body and frame. Look for any signs of wear and address them promptly. Regular cleaning and protective coatings can also help maintain the vehicle’s appearance and structural health.

Upgrades and Modifications Suggestions

Enhancing the performance and functionality of your machine can significantly improve its efficiency and lifespan. This section offers practical ideas for modifications that can lead to better performance, comfort, and usability. Whether you aim to boost power, improve handling, or simply modernize your equipment, consider the following options.

Performance Enhancements

Investing in performance upgrades can provide noticeable improvements in power and efficiency. Here are some suggested modifications:

| Upgrade Type | Description | Benefits |

|---|---|---|

| Air Intake System | Replace the stock intake with a high-flow option. | Increases airflow, resulting in better combustion and power output. |

| Exhaust System | Upgrade to a performance exhaust for reduced back pressure. | Enhances engine efficiency and sound quality. |

| Tuning Chip | Install a tuning chip to optimize engine parameters. | Improves fuel economy and overall performance. |

Comfort and Usability Modifications

Improving user comfort and operational ease is essential for long-term satisfaction. Consider the following enhancements:

| Modification Type | Description | Benefits |

|---|---|---|

| Seat Upgrade | Replace the factory seat with an ergonomic design. | Enhances comfort during extended use. |

| Lighting System | Install LED lights for better visibility. | Improves safety and operational capability in low-light conditions. |

| Instrumentation | Add digital gauges for more accurate readings. | Increases situational awareness and operational efficiency. |

Finding Replacement Parts Effectively

Locating suitable components for your machinery can be a daunting task, yet with the right approach, it becomes manageable. Understanding the various sources and strategies available will ensure that you secure the necessary items efficiently and affordably.

Utilizing Online Resources

The internet is a treasure trove of information and options. Numerous websites specialize in aftermarket and original components. Take advantage of online marketplaces and dedicated parts suppliers to compare prices and availability. Always ensure to check reviews and ratings to avoid subpar products. Additionally, online forums and communities can offer invaluable insights and recommendations from fellow enthusiasts.

Consulting Local Suppliers

Don’t overlook the benefits of local retailers and distributors. Establishing a relationship with nearby shops can lead to better service and quicker access to parts. Often, local suppliers can provide expertise that online resources may lack, helping you identify the correct components for your specific needs. Consider visiting trade shows or local events to network and discover reputable vendors.