Every vehicle requires a comprehensive approach to upkeep, ensuring optimal performance and longevity. Understanding the intricacies of your automobile enhances the ownership experience, allowing for informed decisions regarding its maintenance. This section delves into essential insights, offering guidance on tackling common issues faced by car owners.

Equipping yourself with knowledge about your vehicle’s components and systems is crucial. Familiarity with these elements not only aids in identifying problems early but also empowers you to take proactive measures. The following information serves as a resource for understanding the complexities involved in caring for your automobile.

By utilizing this knowledge effectively, you can avoid unnecessary expenses and enhance the overall driving experience. Whether you’re looking to perform basic checks or undertake more involved procedures, a well-rounded understanding of your vehicle’s needs will prove invaluable.

Having the right instruments is crucial for efficient and effective vehicle maintenance. A well-equipped workshop can make tasks easier and ensure high-quality results. Below is a list of fundamental tools every enthusiast should consider for their automotive projects.

Basic Hand Tools

- Wrenches: Adjustable and fixed-size wrenches for various bolt sizes.

- Screwdrivers: A selection of flathead and Phillips head drivers.

- Pliers: Needle-nose and slip-joint pliers for gripping and bending.

- Hammer: A ball-peen hammer for shaping and driving components.

Diagnostic Equipment

- OBD-II Scanner: For reading trouble codes and diagnosing issues.

- Multimeter: Essential for electrical diagnostics and testing circuits.

- Tire Pressure Gauge: To ensure proper inflation for optimal performance.

Engine Maintenance Procedures

Regular upkeep of the powertrain is essential for ensuring optimal performance and longevity. Following a structured approach to maintenance can help prevent costly repairs and enhance the efficiency of the vehicle. This section outlines key procedures to maintain the engine in peak condition, ensuring smooth operation and reliability.

Fluid Checks and Changes

Regularly monitoring and replacing essential fluids is critical. Engine oil should be checked frequently, and changes should occur based on the manufacturer’s recommendations or if the oil appears dirty. Coolant levels must also be maintained to prevent overheating, while transmission and brake fluids should be inspected and replaced as necessary to ensure proper functioning.

Filter Maintenance

Replacing filters is a vital aspect of engine care. The air filter should be examined and replaced if clogged, as it ensures optimal airflow to the engine. Additionally, the fuel filter plays a significant role in maintaining performance; replacing it regularly can prevent contaminants from affecting engine operation. Following these steps will contribute to the overall health of the vehicle’s powertrain.

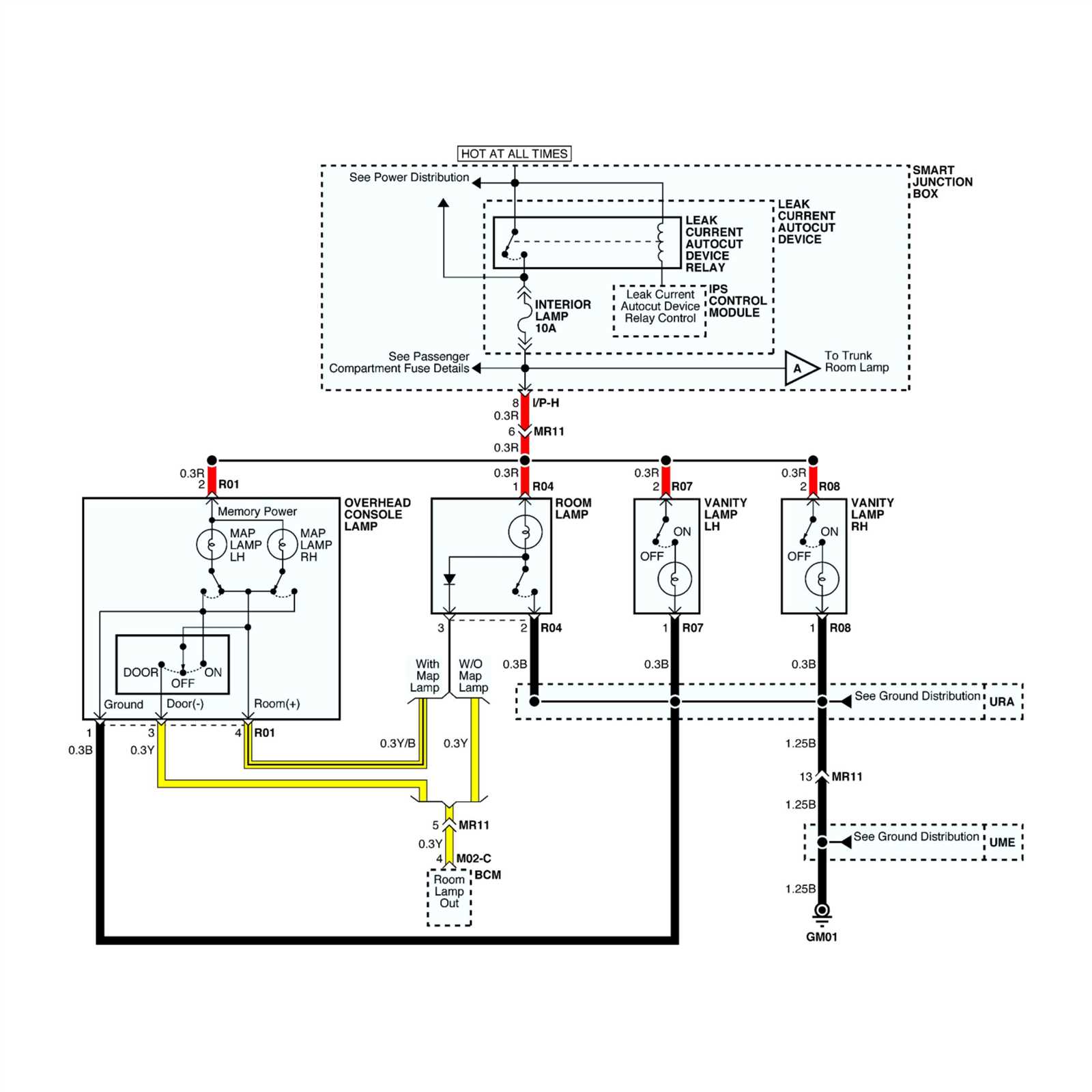

Electrical System Diagnostics

Assessing the functionality of an automobile’s electrical network is crucial for maintaining optimal performance. Proper evaluation ensures that components operate efficiently, preventing potential failures that could compromise vehicle safety and reliability.

Common Electrical Issues

- Battery malfunctions

- Faulty alternator

- Wiring faults

- Defective sensors

Diagnostic Steps

- Begin with a visual inspection of all wiring and connections.

- Test the battery voltage using a multimeter.

- Check the alternator output to ensure proper charging.

- Utilize diagnostic tools to read fault codes from the vehicle’s computer.

By following these steps, one can effectively identify and address electrical problems, ensuring the vehicle remains in peak condition.

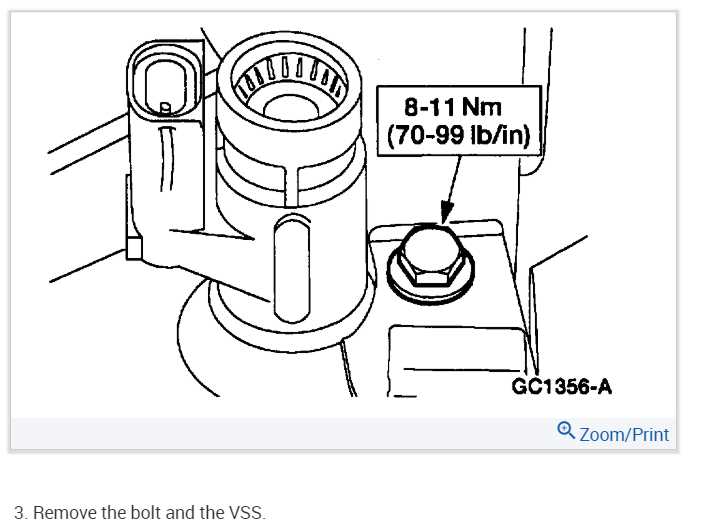

Transmission Troubleshooting Tips

Addressing issues with your vehicle’s transmission can seem daunting, but with a systematic approach, many problems can be diagnosed and resolved effectively. Understanding common symptoms and their possible causes is essential for any vehicle owner.

Here are some general indicators that might suggest transmission issues:

- Unusual noises during gear shifts

- Delayed engagement when shifting from park to drive

- Fluid leaks under the vehicle

- Warning lights illuminated on the dashboard

If you encounter any of these signs, consider the following troubleshooting steps:

- Check Fluid Levels: Ensure the transmission fluid is at the appropriate level, as low fluid can lead to shifting problems.

- Inspect for Leaks: Examine the ground beneath the vehicle for any signs of fluid leaks, which may indicate a seal or gasket failure.

- Examine Connections: Look over wiring and connectors related to the transmission for any signs of damage or corrosion.

- Test for Error Codes: Utilize a diagnostic scanner to check for any error codes that may indicate specific transmission faults.

By following these guidelines, you can systematically identify and address potential transmission issues, leading to more reliable vehicle performance.

Brake System Inspection Guide

Ensuring the functionality of your vehicle’s stopping mechanisms is crucial for safety. Regular evaluation of this essential system helps identify potential issues before they escalate, providing peace of mind while driving.

Key Components to Examine

- Brake Pads: Inspect for wear and tear; replace if they are too thin.

- Rotors: Check for warping or scoring that may affect performance.

- Brake Fluid: Ensure the fluid is at the appropriate level and free of contamination.

- Brake Lines: Look for leaks or signs of corrosion that could lead to failures.

Inspection Steps

- Park the vehicle on a level surface and secure it with wheel chocks.

- Remove the wheel to access the brake components.

- Examine each component thoroughly, noting any irregularities.

- Document findings and decide on necessary repairs or replacements.

Regular inspections not only enhance vehicle safety but also prolong the lifespan of braking components. Always consult a professional if any doubts arise during your examination.

Suspension Components and Care

The suspension system plays a crucial role in providing comfort and stability during driving. Understanding its components and maintaining them properly is essential for ensuring a smooth and safe ride. This section covers the various elements of the suspension setup and highlights the best practices for their upkeep.

Key Elements of the Suspension System

Several critical parts make up the suspension system, each contributing to overall vehicle performance. These include:

- Shock Absorbers: These components help dampen the impact of road irregularities, providing a smoother experience.

- Struts: Often combined with shock absorbers, struts support the vehicle’s weight and assist in steering.

- Springs: They bear the vehicle’s load and help maintain ride height, offering resilience against bumps.

- Control Arms: These parts connect the suspension to the vehicle’s frame, allowing for controlled movement.

Maintenance Tips

Regular inspection and care of the suspension components are vital for longevity and performance. Here are some recommended practices:

- Routine Checks: Inspect the system for signs of wear or damage, particularly on shocks and struts.

- Proper Alignment: Ensure that wheel alignment is regularly checked to prevent uneven tire wear and handling issues.

- Fluid Replacement: Replace shock absorber fluid as necessary to maintain effectiveness.

Cooling System Maintenance Steps

Proper upkeep of the cooling system is essential for the longevity and efficiency of any vehicle. Regular maintenance helps prevent overheating and potential engine damage, ensuring optimal performance. The following steps outline the key practices for maintaining this vital system.

Inspecting Fluid Levels: Regularly check the coolant reservoir to ensure it is filled to the appropriate level. Low coolant can lead to overheating. If necessary, top off with the recommended fluid type, following the manufacturer’s specifications.

Checking for Leaks: Examine hoses and connections for any signs of leaks. Look for coolant stains or puddles underneath the vehicle. Address any leaks promptly to prevent loss of fluid and potential engine issues.

Flushing the System: Periodically flushing the cooling system is crucial to remove contaminants and debris. This process involves draining the old coolant and replacing it with fresh fluid, promoting efficient heat transfer and preventing corrosion.

Testing the Thermostat: The thermostat regulates the engine temperature. Ensure it is functioning correctly by monitoring engine performance. If the engine consistently runs too hot or too cold, consider testing or replacing the thermostat.

Inspecting the Radiator: Regularly check the radiator for any signs of damage, such as corrosion or blockages. Clean the exterior to allow for proper airflow and consider having the radiator professionally serviced if issues are detected.

Bodywork Repair Techniques

When it comes to restoring the exterior of a vehicle, various methods can be employed to ensure a seamless finish. These approaches range from minor touch-ups to extensive panel replacements, depending on the extent of the damage. Mastering these techniques not only enhances the vehicle’s appearance but also contributes to its overall longevity.

Surface Preparation

Before any repair work can commence, the surface must be meticulously prepared. This involves cleaning the area to remove dirt, rust, and old paint. Sanding is crucial for creating a smooth base, allowing new materials to adhere effectively. Additionally, applying a suitable primer helps in achieving a uniform surface for painting.

Panel Replacement and Alignment

In cases of severe damage, replacing the affected panels may be necessary. Proper alignment is essential to ensure that the new parts fit seamlessly with the existing structure. This process often requires precise measurements and adjustments to maintain the vehicle’s original design integrity.

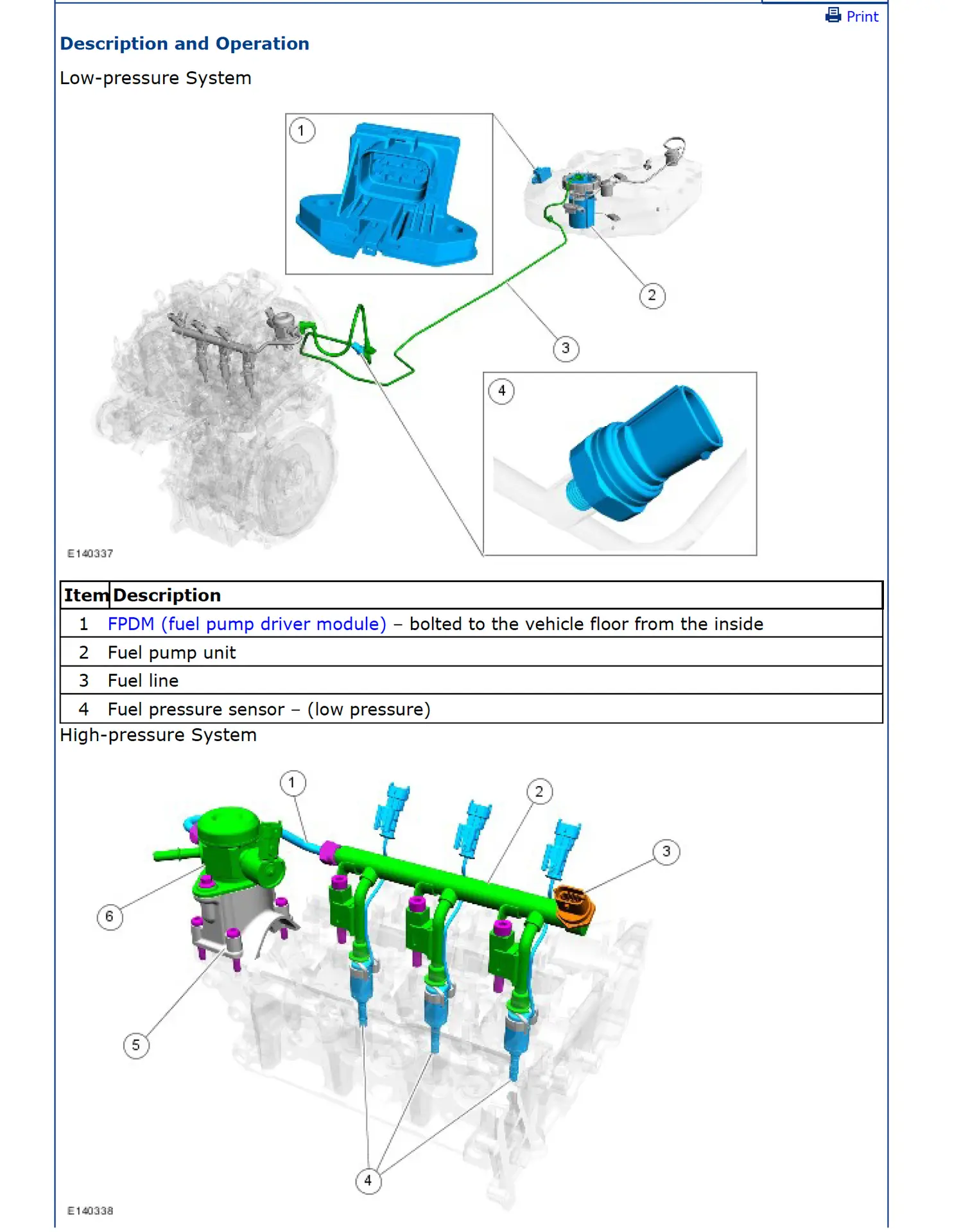

Fuel System Cleaning Methods

Maintaining the cleanliness of the fuel delivery system is essential for optimal engine performance. Various techniques can effectively remove contaminants and buildup, ensuring that fuel flows freely and combustion occurs efficiently.

One popular method involves the use of specialized cleaning solutions that are introduced directly into the fuel tank. These additives are designed to dissolve deposits and enhance the overall cleanliness of the injectors and combustion chamber. Regular application can prevent serious issues related to fuel delivery.

Another effective approach is the use of ultrasonic cleaning. This technique employs high-frequency sound waves to create microscopic bubbles in a cleaning solution. When these bubbles collapse, they produce intense energy that dislodges stubborn grime and residues from fuel injectors and other components.

Manual cleaning can also be performed, particularly for easily accessible parts. Disassembling fuel injectors or other components allows for thorough scrubbing and inspection. It is vital to follow proper procedures to avoid damaging sensitive parts during this process.

Additionally, a fuel system flush can be conducted using specialized equipment. This method circulates a cleaning agent through the entire system, effectively dislodging contaminants and clearing pathways for fuel flow.

Implementing these cleaning strategies not only prolongs the lifespan of the fuel system but also contributes to better fuel efficiency and engine responsiveness. Regular maintenance checks are crucial for identifying any build-up before it leads to performance issues.