When it comes to preserving the functionality and charm of a vintage vehicle, having the right information at your fingertips is crucial. This guide serves as a comprehensive resource for enthusiasts looking to enhance their knowledge and skills in keeping their beloved trucks in top-notch condition. With detailed instructions and insights, you’ll navigate the intricacies of automotive care with confidence.

Understanding the mechanics and maintenance requirements of your classic truck not only prolongs its life but also elevates your driving experience. From routine checks to troubleshooting common issues, the wisdom contained within these pages empowers you to tackle repairs effectively. Emphasizing both safety and performance, this resource aims to equip you with the tools needed for successful upkeep.

Moreover, a well-maintained vehicle can offer an unparalleled connection to the past, blending nostalgia with reliability. Whether you’re a seasoned mechanic or a novice enthusiast, the following sections will guide you through various procedures, ensuring your truck remains a dependable companion on the road. Dive in and discover how to keep your classic ride running smoothly for years to come.

Understanding the 1989 Ford F250

This section delves into the key aspects and features of a classic pickup truck that has earned a loyal following over the years. Known for its durability and performance, this vehicle is often favored by enthusiasts and those seeking a reliable workhorse. Understanding its specifications and mechanics can greatly enhance the ownership experience.

Key Features

Among its standout characteristics, the vehicle boasts a robust engine that delivers impressive torque, making it suitable for both heavy-duty tasks and everyday driving. Its spacious cabin is designed for comfort, accommodating both drivers and passengers with ample legroom. Additionally, the rugged build ensures longevity, making it a popular choice for those who require dependability in their automotive investments.

Maintenance Tips

Proper upkeep is crucial for maximizing the lifespan of this pickup. Regular inspections of the engine, transmission, and suspension components can prevent potential issues. Utilizing quality parts during repairs, alongside adhering to a consistent service schedule, will ensure optimal performance. Staying informed about common wear items can help in anticipating maintenance needs and preserving the truck’s functionality.

Common Issues in the F250 Model

Vehicles from this generation often exhibit a range of typical challenges that can affect their performance and reliability. Understanding these issues can help owners anticipate problems and maintain their trucks more effectively. Below are some prevalent concerns that enthusiasts and mechanics frequently encounter.

Engine Problems

One of the primary areas of concern is the engine, which may experience difficulties such as oil leaks and overheating. Regular inspections are essential to identify signs of wear, especially in the gaskets and seals. Owners should also be aware of potential issues with fuel injectors, which can lead to reduced efficiency and power loss.

Transmission Troubles

Transmission-related complications are another common issue, often manifesting as slipping or harsh shifting. These symptoms can be attributed to low fluid levels or a need for maintenance on the transmission system. It is advisable to perform routine checks to ensure optimal performance and prolong the life of the vehicle.

Essential Tools for Repairs

When it comes to maintaining and restoring vehicles, having the right equipment at your disposal can make all the difference. The effectiveness and efficiency of any task largely depend on the tools used, allowing enthusiasts and professionals alike to achieve optimal results. Understanding the essential instruments will not only streamline the process but also enhance the overall experience of working on your vehicle.

Wrenches are fundamental for loosening and tightening bolts. A comprehensive set that includes various sizes ensures compatibility with numerous fasteners found throughout the machinery. Additionally, ratchets paired with sockets offer versatility, enabling quick adjustments in tight spaces.

Screwdrivers are equally important, with both flathead and Phillips types being necessary for different applications. Investing in a high-quality set ensures durability and better grip, making tasks easier and more efficient. Pliers, including needle-nose and slip-joint varieties, provide the necessary grip and leverage for holding components securely.

For more complex operations, jack stands and floor jacks are crucial for safely lifting the vehicle, allowing for easier access to the undercarriage. Furthermore, multimeters assist in diagnosing electrical issues, helping to identify faulty components effectively.

Lastly, a well-stocked toolbox is vital for organization and accessibility. Keeping all instruments in one place not only saves time but also reduces the frustration of searching for specific tools. By equipping yourself with these essential items, you can approach any vehicle task with confidence and competence.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to ensuring your vehicle remains in optimal condition. Regular upkeep not only enhances performance but also extends the lifespan of essential components. Follow these structured steps to maintain your ride effectively.

1. Routine Inspection: Begin with a thorough visual assessment of your vehicle. Look for signs of wear, leaks, or unusual noises. Regular checks can prevent minor issues from escalating.

2. Fluid Checks: Periodically examine all essential fluids, including engine oil, coolant, brake fluid, and transmission fluid. Ensure levels are adequate and replace or top off as necessary to maintain proper functionality.

3. Tire Maintenance: Inspect tire pressure monthly and adjust as needed. Rotate your tires every 5,000 to 7,000 miles to ensure even wear. Don’t forget to check tread depth for optimal grip.

4. Brake System Evaluation: Regularly assess your brakes for responsiveness and wear. Replace pads and rotors as required to ensure safe stopping power.

5. Battery Care: Keep terminals clean and free from corrosion. Test battery voltage periodically, and replace it if it’s not holding a charge effectively.

6. Air Filter Replacement: Check and replace your air filter every 15,000 to 30,000 miles. A clean filter improves engine performance and fuel efficiency.

7. Belts and Hoses Inspection: Examine belts and hoses for cracks, frays, or leaks. Replace any components that show signs of wear to avoid potential breakdowns.

8. Regular Cleaning: Maintain both the exterior and interior by washing and waxing regularly. Clean surfaces prevent deterioration and keep the vehicle looking new.

9. Follow Manufacturer’s Schedule: Adhere to the maintenance schedule outlined by the manufacturer. Scheduled services often include crucial checks that help sustain vehicle health.

By following this step-by-step guide, you can ensure your vehicle runs smoothly and remains reliable for years to come.

Engine Specifications and Diagnostics

This section delves into the crucial aspects of engine characteristics and troubleshooting methods, providing essential information for effective maintenance and performance optimization. Understanding the fundamental specifications helps in diagnosing potential issues and ensures the engine operates efficiently.

Key Specifications

Engine specifications include displacement, horsepower, torque, and fuel type. Displacement is measured in liters or cubic inches, representing the engine’s size and capacity for air-fuel mixture intake. Horsepower indicates the engine’s power output, while torque reflects its rotational force, both critical for understanding performance. Additionally, the recommended fuel type influences efficiency and engine longevity.

Diagnostics Techniques

Effective diagnostics involve using various tools and techniques to identify and resolve engine problems. Common methods include visual inspections, pressure tests, and electronic diagnostics. Utilizing an OBD-II scanner can provide valuable error codes that indicate specific issues, while a compression test assesses the health of the cylinders. Regular monitoring of engine parameters ensures early detection of anomalies, ultimately enhancing reliability.

Transmission Troubleshooting Tips

When faced with issues related to vehicle gear systems, it’s essential to approach the problem systematically. Understanding the common symptoms and identifying potential causes can significantly simplify the diagnosis process. This guide provides practical advice to help you effectively address and resolve transmission-related concerns.

1. Check Fluid Levels: Low transmission fluid can lead to shifting problems and overheating. Regularly inspect the fluid levels and top off as needed, ensuring that you use the correct type specified for your vehicle.

2. Look for Leaks: Fluid leaks are a common issue that can affect performance. Examine the ground beneath your vehicle and the components around the transmission for signs of leaking fluid.

3. Listen for Unusual Noises: Grinding, whining, or clunking sounds can indicate internal problems. Pay attention to these noises while shifting gears, as they can provide clues about the underlying issue.

4. Monitor Shifting Behavior: Hesitation, slipping, or harsh shifts can signal trouble. Take note of when these issues occur–during acceleration, deceleration, or at specific speeds–and communicate these details during any inspection.

5. Check for Warning Lights: Dashboard alerts related to the transmission should not be ignored. Use an OBD-II scanner to retrieve trouble codes, which can guide your troubleshooting efforts.

6. Perform a Visual Inspection: Examine the transmission and its connections for any signs of damage, wear, or corrosion. Ensure that all cables and hoses are securely attached and free from obstruction.

7. Consult Professional Help: If you’ve exhausted basic troubleshooting steps without success, seeking assistance from a qualified technician can provide deeper insights. Their expertise can help pinpoint complex issues that may not be immediately apparent.

By following these troubleshooting tips, you can gain a better understanding of your vehicle’s transmission issues and take informed steps toward resolution.

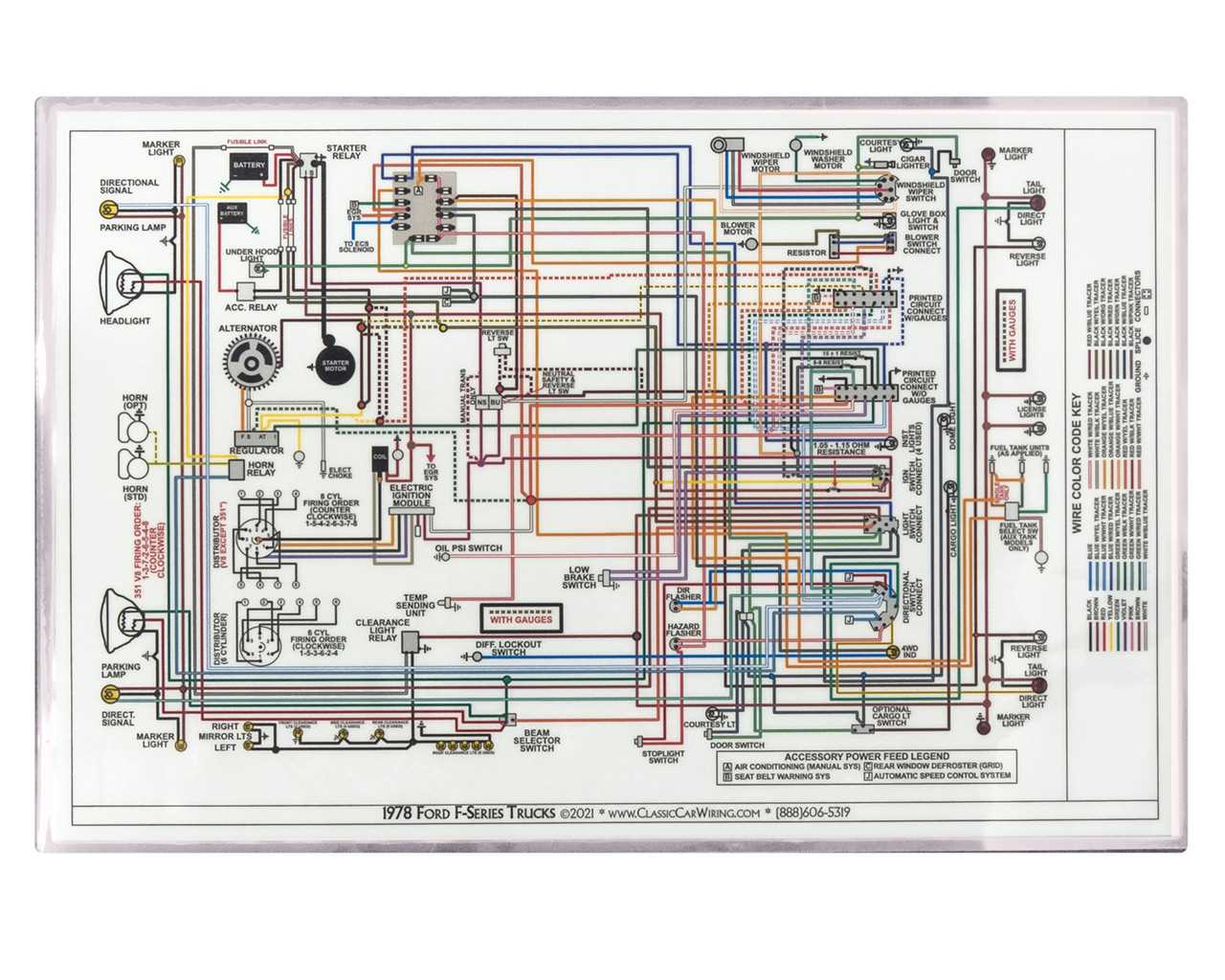

Electrical System Repair Insights

The electrical system of a vehicle is a complex network that powers various components, from lighting to ignition. Understanding its intricacies is essential for effective troubleshooting and maintenance. This section delves into critical aspects of electrical system care, providing valuable insights for those looking to enhance their knowledge and skills.

Common Issues and Diagnostics

Identifying issues within the electrical framework often requires a systematic approach. Common problems include battery failures, faulty wiring, and malfunctioning components. Utilizing a multimeter can help determine voltage levels and continuity, while visual inspections can reveal damaged or corroded connections. Regular checks can prevent larger malfunctions and ensure reliability.

Preventative Measures

Implementing preventative strategies can significantly extend the life of the electrical system. Routine maintenance, such as cleaning terminals and ensuring tight connections, can mitigate wear and tear. Additionally, protecting wiring from abrasion and exposure to moisture is crucial. Utilizing quality replacement parts also enhances overall system integrity, reducing the likelihood of future issues.

Suspension and Steering Adjustments

Proper alignment and calibration of the suspension and steering systems are crucial for optimal vehicle performance and safety. These adjustments ensure that the ride remains smooth and that the vehicle responds accurately to driver input. Regular maintenance in this area helps to prolong the lifespan of components and enhance overall handling.

Key adjustments to consider include:

- Wheel alignment

- Toe settings

- Caster angles

- Camber angles

- Shock absorber settings

To achieve accurate adjustments, follow these essential steps:

- Check tire pressure and tread condition.

- Inspect suspension components for wear or damage.

- Utilize appropriate alignment tools to measure angles.

- Make necessary adjustments to achieve manufacturer specifications.

- Test drive the vehicle to confirm improvements in handling.

Regular inspections and timely adjustments can significantly enhance driving comfort and safety. Ensuring that these systems are functioning optimally will not only improve vehicle dynamics but also contribute to a smoother ride.

Brake System Maintenance Techniques

Maintaining the braking system is essential for ensuring optimal performance and safety of your vehicle. Regular checks and proactive care can significantly extend the lifespan of braking components, enhance responsiveness, and reduce the risk of malfunctions.

Routine Inspection

Conducting periodic examinations of the braking system is crucial. Look for signs of wear on brake pads and rotors, ensuring they are not excessively thin. Additionally, check for fluid leaks, as hydraulic fluid is vital for the system’s operation. A quick visual inspection can help identify potential issues before they become serious problems.

Fluid Replacement

Brake fluid should be changed at regular intervals to maintain the system’s integrity. Over time, brake fluid can absorb moisture, which can lead to corrosion and reduced effectiveness. Always refer to the manufacturer’s guidelines for the recommended intervals, and ensure that only the appropriate type of fluid is used. Regularly flushing the system can help prevent buildup and maintain optimal performance.

Proper maintenance not only ensures safety but also enhances the overall driving experience. Investing time in these techniques pays off by preventing costly repairs and keeping your vehicle in prime condition.

Bodywork and Rust Prevention

Maintaining the integrity of a vehicle’s exterior is essential for both aesthetic appeal and longevity. Effective strategies for protecting against corrosion and physical damage can significantly enhance a vehicle’s lifespan. Addressing potential vulnerabilities early can prevent costly repairs and ensure the body remains in optimal condition.

Regular inspection of the surface is crucial. Look for chips, scratches, or any signs of wear that could expose the underlying metal. Promptly addressing these issues with appropriate touch-up paint or sealants can minimize the risk of rust formation. Additionally, applying a protective wax or sealant layer can provide a barrier against environmental factors such as moisture and road salt.

When performing any bodywork, it’s important to use high-quality materials designed specifically for automotive applications. This ensures not only a better finish but also enhanced durability against the elements. Furthermore, considering a thorough cleaning regimen, including undercarriage washing, can help remove contaminants that contribute to rust development.

Lastly, storing the vehicle in a sheltered environment can significantly reduce exposure to harsh weather conditions. Utilizing car covers when parking outside and regularly applying rust inhibitors can create an extra layer of protection, ensuring that the vehicle remains both visually appealing and structurally sound for years to come.

Finding Genuine Parts and Resources

Locating authentic components and reliable references is crucial for maintaining the longevity and performance of your vehicle. Utilizing high-quality parts not only ensures optimal functionality but also enhances safety and efficiency. This section provides guidance on where to find these essential resources.

Where to Search for Authentic Components

- Authorized Dealerships: These establishments often stock genuine parts and provide expertise on compatibility.

- Specialized Retailers: Look for stores that focus on automotive supplies, as they usually carry a range of authentic options.

- Online Marketplaces: Websites dedicated to automotive parts can offer a wide selection, but verify the seller’s reputation.

- Local Junkyards: Salvage yards can be treasure troves for hard-to-find components at a fraction of the cost.

Additional Resources for Support

- Online Forums: Communities dedicated to automotive enthusiasts can provide advice and share experiences.

- Repair Guides: Comprehensive manuals available online can help in understanding installation and maintenance processes.

- Manufacturer Websites: Official sites often have parts catalogs and can direct you to authorized suppliers.

- Automotive Clubs: Joining local or national groups can connect you with knowledgeable individuals and exclusive resources.

Safety Considerations During Repairs

Ensuring safety while undertaking maintenance tasks is paramount. Proper precautions not only protect the individual performing the work but also safeguard the equipment being serviced. Awareness and adherence to safety guidelines can prevent accidents and injuries, making the process more efficient and less stressful.

Essential Safety Gear

- Protective eyewear: Always wear safety glasses to shield your eyes from debris.

- Gloves: Use gloves to protect your hands from sharp edges and hazardous substances.

- Steel-toed boots: Footwear with reinforced toes can prevent injuries from heavy objects.

- Hearing protection: If working in noisy environments, consider using earplugs or earmuffs.

- Dust masks: These are important when working with materials that generate dust or fumes.

Workspace Organization

Maintaining a tidy and organized workspace is crucial for safety. Here are some tips to achieve this:

- Clear clutter: Remove unnecessary items that can obstruct movement or become trip hazards.

- Proper lighting: Ensure adequate illumination to avoid missteps and errors.

- Tool management: Keep tools stored safely when not in use and within easy reach during tasks.

- Emergency access: Ensure that exits are unobstructed to allow for quick evacuation in case of an emergency.