Ensuring the longevity and optimal performance of any automobile requires a systematic approach and a clear understanding of its structure and functionality. This guide serves as an essential resource for anyone looking to keep their vehicle in top condition through informed and precise maintenance practices.

When tackling issues related to the engine, transmission, or electrical systems, having a reliable source of information can make the process smoother and less daunting. The goal of this section is to provide detailed and clear insights to help enthusiasts and professionals alike address and resolve common automotive problems efficiently.

From routine upkeep to more intricate adjustments, this document offers a step-by-step approach that empowers vehicle owners to perform essential tasks with confidence. With an emphasis on clarity and practicality, the guidance here aims to equip readers with the knowledge to identify issues, apply fixes, and enhance overall reliability.

Hummer H3 Chilton Repair Manual

The comprehensive guide for the H3 offers detailed step-by-step instructions to maintain and troubleshoot the vehicle effectively. This section focuses on the essential technical insights and procedures, ensuring that the vehicle remains in optimal condition. The instructions presented help navigate complex systems, empowering owners and technicians with the knowledge to handle a wide range of issues.

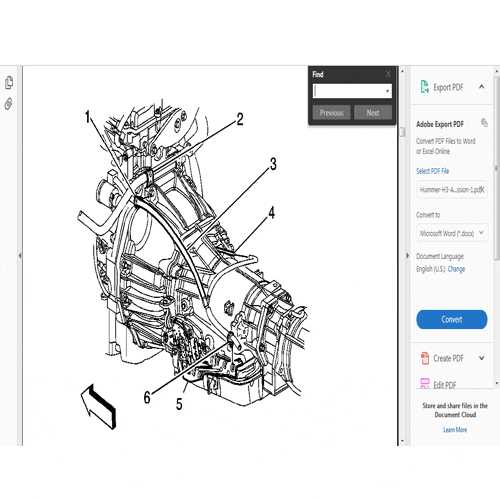

Detailed System Overview

Covering each system thoroughly, the guide provides an in-depth analysis of components and their interconnections. It highlights the crucial areas to monitor and key parts that often require attention. This comprehensive breakdown enables users to gain a better understanding of the internal workings and make informed maintenance decisions.

Step-by-Step Procedures

The guide includes precise instructions for various tasks, from regular upkeep to complex troubleshooting. By following these systematic guidelines, users can efficiently address common challenges. Each procedure is crafted to ensure clarity, efficiency, and reliability, helping to minimize errors and reduce maintenance time.

Engine Diagnostics and Troubleshooting

Effective diagnostics and troubleshooting are crucial for maintaining optimal engine performance. By understanding the core components and recognizing early warning signs, potential issues can be identified and addressed promptly to prevent costly repairs.

Identifying Common Symptoms

Recognizing the symptoms of engine problems early is essential. Drivers should be attentive to unusual noises, warning lights, or performance drops. Typical indicators might include engine knocking, loss of power, or overheating.

- Unusual Noises: Persistent knocking or grinding can point to mechanical faults.

- Overheating: Inadequate cooling or coolant leaks can lead to increased engine temperatures.

- Decreased Efficiency: Poor fuel consumption or sluggish acceleration are signs of underlying issues.

Steps for Basic Troubleshooting

Following a structured approach when diagnosing an engine is key. Start with simple checks and progress to more detailed inspections if problems persist.

- Radiator: Responsible for dissipating heat from the engine coolant.

- Water Pump: Circulates coolant throughout the system, ensuring effective heat exchange.

- Thermostat: Regulates the engine temperature by controlling coolant flow.

- Heater Core: Functions like a small radiator, providing heat to the cabin when required.

- Blower Motor: Facilitates air circulation within the cabin, distributing heated or cooled air.

- Gather Required Materials:

- New oil filter

- Fresh engine oil

- Oil catch pan

- Wrench or oil filter removal tool

- Funnel

- Gloves and rags for cleanup

- Prepare the Vehicle:

- Park on a level surface and engage the parking brake.

- Allow the engine to cool if it has been running.

- Drain Old Oil:

- Position the oil catch pan under the oil pan.

- Remove the drain plug and allow the old oil to flow into the pan.

- Replace the drain plug once all the oil has drained.

- Replace the Oil Filter:

- Locate the oil filter and use the removal tool to take it off.

- Lubricate the rubber gasket of the new filter with a bit of fresh oil.

- Install the new filter, tightening it according to the manufacturer’s specifications.

- Add New Oil:

- Open the hood and remove the oil filler cap.

- Using a funnel, pour in the recommended amount of new oil.

- Replace the oil filler cap securely.

- Check Oil Level:

- Start the engine and let it run for a few minutes.

- Turn off the engine and wait a minute before checking the dipstick.

- Add oil if necessary to reach the appropriate level.

- Tires: Upgrading to all-terrain or mud-terrain tires provides better grip and control on uneven surfaces.

- Suspension System: Installing a lift kit can increase ground clearance, reducing the risk of undercarriage damage and improving approach and departure angles.

- Performance Exhaust: Enhancing the exhaust system can improve airflow, resulting in better engine performance and efficiency.

- Engine Tuning: Adjusting the engine settings can optimize power delivery, particularly in low-end torque for climbing steep inclines.

- Skid Plates: Adding protective plates shields vital components from rocks and debris, enhancing durability in harsh conditions.

Transmission System Maintenance Tips

Regular upkeep of the vehicle’s transmission is crucial to ensuring optimal performance and longevity. A well-maintained system not only enhances driving comfort but also prevents costly breakdowns and extensive repairs. This section provides essential guidance to help extend the life of this key component.

Check Fluid Levels and Condition

Inspecting the fluid regularly is vital to maintaining a healthy transmission. Ensure the fluid level is within the recommended range and look for signs of discoloration or a burnt odor, which may indicate contamination or overheating. In such cases, replacing or flushing the fluid might be necessary.

Monitor System for Leaks

Keep an eye on potential leaks, as even small drips can escalate into serious issues over time. Pay attention to any puddles under the vehicle, and periodically examine seals and gaskets for wear or damage. Addressing leaks promptly can prevent further complications and keep the system functioning smoothly.

| Maintenance Task | Frequency | Importance | ||||||

|---|---|---|---|---|---|---|---|---|

| Fluid Check | Every 3,000 miles | High | ||||||

| Component | Adjustment Type | Purpose |

|---|---|---|

| Front Camber | Adjusting Upper Control Arms | Improves tire contact and cornering stability |

| Toe Angle | Modifying Tie Rods | Enhances

Electrical System Testing and UpkeepEnsuring the functionality and longevity of a vehicle’s electrical components is essential for optimal performance. Regular evaluation of the electrical system helps identify potential issues before they escalate, contributing to a reliable driving experience. This section outlines key practices for testing and maintaining the electrical system in your vehicle. Routine InspectionsRegular assessments of the electrical components, such as the battery, wiring, and connectors, are crucial. Visual inspections should be conducted to check for signs of wear, corrosion, or loose connections. Keeping these components in good condition prevents unexpected failures and enhances overall efficiency. Testing ProceduresUtilizing appropriate diagnostic tools allows for accurate testing of the electrical system. Multimeters can measure voltage and resistance, aiding in identifying faulty components. Additionally, ensuring the battery is charged and functioning properly is fundamental. Regular tests help maintain the reliability of the vehicle’s electrical infrastructure. Body and Frame Damage RepairAddressing issues related to structural integrity is crucial for maintaining vehicle safety and performance. The process involves assessing the extent of damage to both the exterior casing and the foundational structure, ensuring that all repairs restore the vehicle to its original specifications. This section outlines essential techniques and considerations for effectively rectifying these types of impairments. Assessment and InspectionBefore commencing any restoration work, a thorough evaluation of the damaged areas is necessary. Utilize specialized tools to identify bends, cracks, or other distortions in the structure. Documenting these findings will assist in determining the required repairs and parts. Pay particular attention to alignment, as misalignments can affect handling and safety. Repair TechniquesWhen dealing with frame issues, various methods can be employed. For minor distortions, techniques such as heat application or cold straightening can restore the original shape. In cases of severe damage, replacement sections may be necessary. Ensure that all components are securely welded or bolted in place, and always follow industry guidelines for strength and safety. Cooling and Heating System OverviewThe cooling and heating system plays a vital role in maintaining comfort within the vehicle’s cabin while also ensuring optimal engine performance. This system is designed to regulate the temperature of the engine and provide a pleasant atmosphere for occupants, balancing both heating and cooling functions effectively. Understanding the key components of this system is essential for proper maintenance and troubleshooting. The primary elements include: Maintaining this system involves regular checks and potential repairs to ensure optimal operation. Common issues may include leaks, coolant level discrepancies, or component malfunctions, which can lead to overheating or inadequate cabin comfort. Regular inspections and timely interventions can significantly extend the lifespan of the cooling and heating system. Routine Oil Change ProceduresRegular maintenance of engine lubrication is essential for optimal vehicle performance and longevity. This section outlines the necessary steps to efficiently replace the oil and filter, ensuring the engine runs smoothly. The following steps will guide you through the oil replacement process: Following these steps will help maintain the engine’s efficiency and extend its operational life. Regularly changing the lubrication fluid is a key aspect of vehicle upkeep. Fuel System Cleaning and OptimizationMaintaining the cleanliness and efficiency of the fuel delivery system is essential for the overall performance of a vehicle. Regular cleaning and optimization can enhance fuel atomization, reduce emissions, and improve fuel economy. A well-maintained system ensures that the engine receives the right mixture of air and fuel, which is crucial for optimal combustion. Regular Inspection: Periodic checks of the fuel system components are vital. Inspecting fuel lines, filters, and injectors for blockages or leaks can prevent issues that may lead to poor engine performance. Identifying and addressing these problems early can save time and repair costs. Cleaning Techniques: Various methods are available to clean fuel injectors and other components. Chemical cleaners can be introduced through the fuel system to dissolve deposits. Alternatively, ultrasonic cleaning can effectively remove stubborn contaminants. Utilizing the appropriate method ensures that the components are thoroughly cleaned without causing damage. Optimization Strategies: Enhancing fuel efficiency can also involve recalibrating the fuel injection system. Adjusting the fuel-to-air ratio can lead to improved combustion and overall engine efficiency. Implementing performance upgrades, such as high-flow fuel pumps or upgraded injectors, can further enhance fuel delivery, resulting in noticeable performance improvements. In summary, keeping the fuel system clean and optimized is crucial for a vehicle’s longevity and efficiency. Regular maintenance, appropriate cleaning techniques, and optimization strategies can significantly enhance performance and reduce overall emissions. Off-Road Performance EnhancementsImproving off-road capabilities can significantly enhance the driving experience, allowing vehicles to tackle challenging terrains with ease. Various modifications can boost traction, stability, and overall power, ensuring a thrilling adventure on rugged paths. Key enhancements to consider include: Each modification can be tailored to meet specific off-road demands, ensuring that enthusiasts are well-equipped for their adventures. |