When it comes to ensuring optimal performance and longevity of your automobile, having access to a thorough resource is invaluable. Such a guide not only provides essential insights into routine upkeep but also assists in troubleshooting various issues that may arise during the vehicle’s lifecycle. Understanding these components is crucial for both novice and experienced car enthusiasts alike.

In this context, navigating through a detailed compilation of information can empower vehicle owners to tackle challenges head-on. From understanding engine specifications to comprehending the intricacies of electrical systems, the right resource will serve as a reliable companion. It transforms daunting tasks into manageable projects, fostering confidence and self-sufficiency.

Additionally, the ability to perform maintenance independently can lead to significant cost savings and a deeper appreciation for the mechanics of one’s own vehicle. Emphasizing hands-on experience and practical knowledge, such a guide opens the door to a rewarding journey of automotive care, enriching both skills and understanding.

Overview of the 2002 Chevy Blazer

This section provides a comprehensive insight into a mid-size SUV that has left a significant mark in the automotive world. Known for its rugged design and versatile performance, this vehicle combines utility with comfort, making it suitable for both urban and off-road adventures.

The model features a robust engine lineup, delivering a balance of power and efficiency. Its spacious interior accommodates passengers and cargo, catering to families and outdoor enthusiasts alike. The design emphasizes both aesthetic appeal and functionality, with a focus on user-friendly technology and safety features.

Common Issues with the Blazer

Owners often encounter a range of typical challenges with this vehicle model, which can affect performance and reliability. Understanding these common problems can aid in proactive maintenance and enhance the driving experience.

Engine Performance: One frequent issue pertains to engine performance, including rough idling and stalling. These symptoms may arise from fuel delivery problems or issues with the ignition system, necessitating thorough diagnostics.

Transmission Troubles: Many users report difficulties with gear shifting, which can be attributed to transmission fluid leaks or faulty sensors. Regular checks can help identify these issues early, preventing more severe complications.

Electrical Systems: Electrical gremlins are another concern, often manifesting as erratic behavior in lights or the dashboard. Investigating the wiring and battery connections can resolve many of these anomalies.

Suspension and Steering: Drivers may notice irregular handling or noises from the suspension. Worn-out components like bushings or shocks can lead to an uncomfortable ride, making timely replacements essential.

Addressing these common challenges promptly can significantly improve the longevity and reliability of this vehicle, ensuring a smoother and safer driving experience.

Essential Tools for Repairs

Having the right equipment is crucial for effectively addressing automotive issues. A well-equipped workspace allows for efficient diagnostics and facilitates successful completion of various tasks. Below are some key implements that every enthusiast or professional should consider having on hand.

| Tool | Description |

|---|---|

| Socket Set | A versatile collection of sockets in different sizes, essential for loosening or tightening bolts and nuts. |

| Wrench Set | Includes various types of wrenches, providing leverage for turning fasteners in tight spaces. |

| Jack and Jack Stands | Used to lift the vehicle safely, allowing access to the undercarriage for inspections and repairs. |

| Multimeter | A diagnostic tool for measuring voltage, current, and resistance, essential for electrical troubleshooting. |

| Oil Filter Wrench | Specialized tool for removing and installing oil filters, making oil changes more efficient. |

| Torque Wrench | Ensures fasteners are tightened to the manufacturer’s specifications, preventing over- or under-tightening. |

| Diagnostic Scanner | A device that connects to the vehicle’s computer system to read error codes and monitor performance. |

Equipping your workspace with these fundamental tools can greatly enhance your ability to troubleshoot and resolve a range of mechanical challenges, ensuring smoother operations and improved performance.

Engine Maintenance Tips

Proper upkeep of your vehicle’s powertrain is crucial for ensuring longevity and optimal performance. Regular attention to various components can prevent costly repairs and enhance efficiency. Here are some essential practices to maintain your engine effectively.

- Regular Oil Changes: Fresh oil lubricates engine parts and reduces wear. Follow the manufacturer’s schedule for changes.

- Check Fluid Levels: Monitor coolant, brake fluid, transmission fluid, and power steering fluid to ensure everything operates smoothly.

- Inspect Air Filters: Clean or replace air filters as needed to maintain proper airflow and engine performance.

- Monitor Belts and Hoses: Regularly inspect for signs of wear, cracking, or fraying, and replace them as necessary.

- Examine Spark Plugs: Check and replace spark plugs to ensure efficient combustion and fuel economy.

Adhering to these guidelines will not only keep your engine running smoothly but also enhance your driving experience while extending the life of your vehicle.

Transmission Troubleshooting Guide

This section aims to assist vehicle owners in diagnosing common issues related to the transmission system. By identifying symptoms and understanding potential causes, users can take informed steps toward resolving problems effectively.

One of the first indicators of transmission trouble is slipping, where the engine revs unexpectedly while the vehicle fails to accelerate as intended. This can signal low fluid levels or worn components. Checking the transmission fluid level and condition is crucial; it should be clean and at the proper level for optimal performance.

Unusual noises during gear changes can also point to underlying issues. Grinding, clunking, or whining sounds might indicate that the transmission gears or bearings are damaged. Regular inspection of these components can help in early detection and prevention of more severe damage.

If the vehicle hesitates or experiences rough shifting, it could be due to issues with the transmission control module or solenoids. Running a diagnostic scan can reveal error codes that assist in pinpointing the specific malfunction.

Overheating can lead to significant transmission problems. Ensure that the cooling system is functioning correctly and that the transmission cooler is free of debris. Regular maintenance, including fluid changes, can mitigate overheating risks and prolong the life of the transmission.

Lastly, if the check engine light illuminates, it is essential to investigate the cause promptly. Ignoring this warning can result in severe transmission failure. Using an OBD-II scanner can provide valuable insights into potential issues, enabling timely intervention.

Electrical System Diagnosis Techniques

Identifying issues within an electrical framework is crucial for ensuring optimal performance and longevity of a vehicle. Mastering various diagnostic methods empowers technicians to efficiently pinpoint problems, facilitating timely repairs and minimizing downtime. This section outlines essential techniques to effectively evaluate and troubleshoot electrical components.

Visual Inspection

The first step in diagnosing electrical issues often involves a thorough visual examination. Technicians should look for signs of wear, corrosion, or damage in wiring and connectors. This preliminary check can reveal obvious problems that may be affecting the system’s functionality.

Using Diagnostic Tools

After conducting a visual assessment, employing diagnostic tools becomes essential for a deeper analysis. Multimeters, oscilloscopes, and scan tools can provide valuable data about voltage, resistance, and signals within the system. Understanding how to interpret this data is key to diagnosing faults accurately.

| Technique | Description | Tools Required |

|---|---|---|

| Visual Inspection | Check for visible damage or corrosion in wiring and connectors. | None |

| Multimeter Testing | Measure voltage, current, and resistance in circuits. | Digital Multimeter |

| Signal Testing | Analyze electrical signals for irregularities. | Oscilloscope |

| Scan Tool Diagnostics | Retrieve and interpret error codes from the vehicle’s computer. | OBD-II Scan Tool |

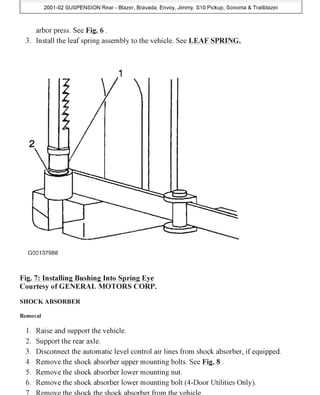

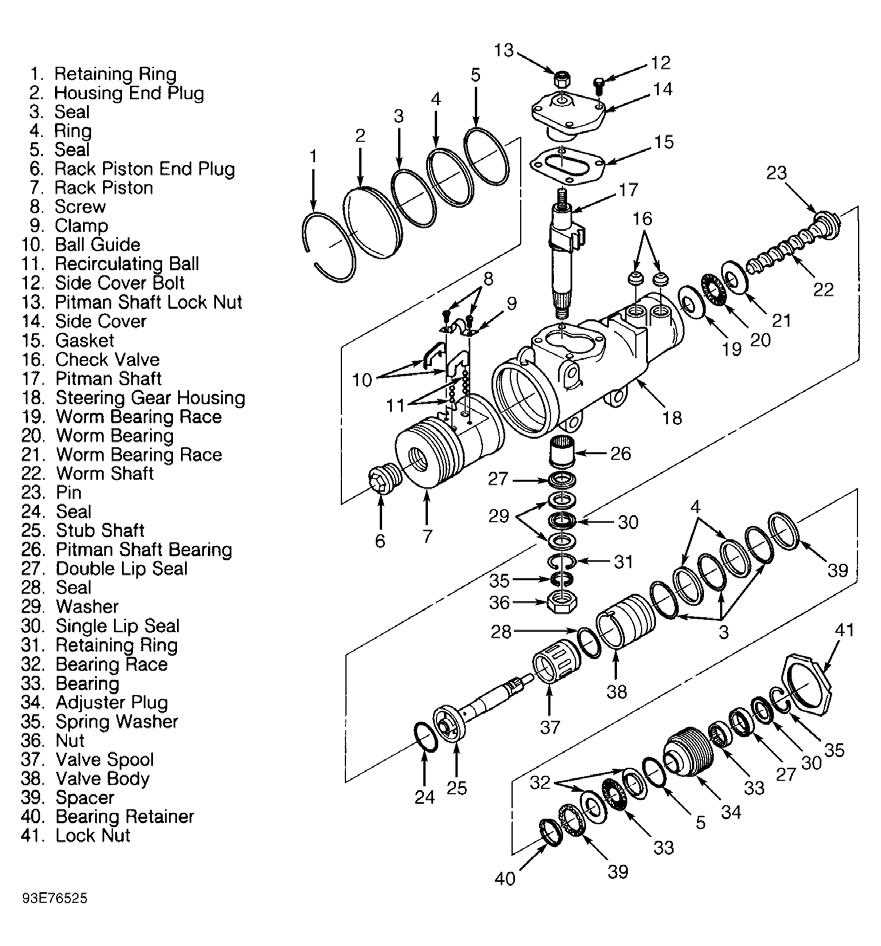

Suspension and Steering Repairs

This section focuses on the essential aspects of maintaining and fixing the suspension and steering systems of your vehicle. These components are crucial for ensuring a smooth ride and precise handling. Understanding their functions and potential issues can help in identifying problems early and taking appropriate action to keep your vehicle operating safely.

When addressing suspension issues, it’s important to regularly inspect parts such as shocks, struts, and springs for signs of wear or damage. Common symptoms of suspension problems include unusual noises, a bumpy ride, or uneven tire wear. By keeping an eye on these indicators, you can prevent further complications and costly repairs down the line.

The steering system, including components like the steering rack, tie rods, and power steering pump, requires attention as well. Difficulty in steering, a misaligned steering wheel, or leaking fluid can signal that something is amiss. Routine checks and maintenance can enhance responsiveness and improve overall driving experience.

Both systems work in harmony to provide stability and control. Regular maintenance and prompt repairs not only prolong the lifespan of these components but also contribute to overall safety on the road. Being proactive in addressing any concerns can save time, money, and ensure a reliable performance of your vehicle.

Brake System Inspection Procedures

Ensuring the optimal performance of the braking system is crucial for vehicle safety. Regular evaluation of various components helps identify potential issues that could affect braking efficiency. This section outlines essential steps for examining the braking mechanism to maintain its functionality and reliability.

Visual Inspection

Begin with a thorough visual examination of the braking system. Check for any signs of wear, such as cracks or uneven surfaces on the brake pads and rotors. Look for fluid leaks around the calipers and lines, as these can indicate a malfunction. Additionally, assess the condition of the brake hoses for any bulging or damage that may compromise their integrity.

Functional Testing

After completing the visual inspection, perform functional tests to assess the system’s performance. Engage the brakes while stationary to evaluate the response and listen for any unusual noises. During a test drive, observe the vehicle’s stopping power and monitor for any vibrations or pulling to one side, which could suggest an underlying issue with the braking system. Regularly conducting these evaluations can help ensure safe driving conditions.

Cooling System Maintenance Strategies

Effective management of the cooling system is essential for ensuring optimal engine performance and longevity. Regular upkeep helps prevent overheating, reduces wear and tear, and enhances overall vehicle reliability. By implementing strategic maintenance practices, you can ensure that this vital system functions smoothly and efficiently.

Begin by routinely checking the coolant levels and inspecting for any leaks. Low coolant can lead to severe engine damage, so maintaining the appropriate level is crucial. Additionally, it’s important to flush the cooling system periodically to remove contaminants and prevent corrosion. This process helps maintain the efficiency of the radiator and other components.

Inspecting hoses and clamps for signs of wear is another key aspect of maintenance. Cracks, bulges, or soft spots can indicate potential failures, so replacing damaged parts promptly can prevent larger issues. Similarly, monitor the thermostat’s performance to ensure it opens and closes at the right temperatures, aiding in proper cooling regulation.

Finally, keeping an eye on the water pump is vital, as it circulates coolant throughout the system. Listen for unusual noises or observe any coolant leaks around the pump, which could signify impending failure. Regular maintenance not only extends the life of the cooling system but also contributes to the overall health of the engine.

Fuel System Cleaning Methods

Maintaining a clean fuel system is essential for optimal engine performance and longevity. Various techniques can effectively remove deposits and contaminants, ensuring that fuel flows freely and combusts efficiently. This section explores some of the most common methods used to clean fuel systems, highlighting their advantages and considerations.

Chemical Cleaners

One popular approach involves the use of chemical cleaning solutions. These specialized products are designed to break down carbon buildup and other deposits within the fuel system. They can be added directly to the fuel tank or injected into the intake system, allowing them to circulate through the entire fuel delivery network. Regular use of these cleaners can help maintain fuel injectors and improve overall engine efficiency.

Manual Cleaning Techniques

For more thorough maintenance, manual cleaning techniques may be employed. This often includes disassembling components such as injectors and the fuel rail to physically remove buildup. Cleaning can involve ultrasonic baths or scrubbing with appropriate solvents. While this method is labor-intensive, it can yield significant results, especially for vehicles experiencing severe performance issues due to a clogged fuel system.

Ultimately, selecting the right cleaning method depends on the specific needs of the vehicle and the condition of its fuel system. Regular maintenance can prevent more serious issues down the line.

Body and Interior Care Suggestions

Maintaining the appearance and condition of your vehicle’s exterior and interior is essential for preserving its value and enhancing your driving experience. Regular care not only keeps your ride looking great but also protects it from wear and tear that can lead to costly repairs.

Exterior Care: Start by regularly washing the surface to remove dirt, grime, and contaminants that can damage the paint. Use a gentle soap formulated for automobiles, and always dry the surface to prevent water spots. Applying a high-quality wax every few months provides a protective layer against the elements, helping to maintain shine and prevent oxidation.

Interior Maintenance: Keep the inside clean by vacuuming the upholstery and carpets frequently. Use appropriate cleaners for different materials, ensuring you don’t damage the surfaces. Protect the dashboard and trim from fading by using a UV protectant. Regularly conditioning leather seats can prevent cracking and keep them looking new.

Additional Tips: Consider using sunshades to minimize heat buildup and protect the interior from sun damage. Address any spills or stains immediately to prevent permanent marks. Regularly check for signs of wear or damage, and address these issues promptly to maintain the overall quality of your vehicle.

DIY vs. Professional Repairs

When it comes to maintaining your vehicle, deciding between self-service and hiring an expert can be a pivotal choice. Each approach offers distinct advantages and challenges, and understanding these can help you make an informed decision that aligns with your skills, time, and budget.

| Aspect | DIY Approach | Professional Service |

|---|---|---|

| Cost | Generally lower; mainly parts and tools | Higher; includes labor and overhead |

| Time | Varies; can take longer due to learning curve | Typically quicker; experienced technicians |

| Expertise | Limited to personal knowledge and research | Access to specialized training and experience |

| Quality | Dependent on individual skill and technique | Consistent and reliable, backed by warranty |

| Convenience | Can work on your schedule | May require scheduling and wait times |

Ultimately, the choice between these two options depends on your confidence in tackling automotive tasks, your available resources, and the specific needs of your vehicle. Weighing these factors will guide you toward the most suitable solution.

Finding Reliable Replacement Parts

When maintaining a vehicle, sourcing trustworthy components is essential for ensuring optimal performance and longevity. The market offers a variety of options, but distinguishing between quality parts and inferior substitutes can be challenging. Understanding where to look and what to consider can significantly impact the overall maintenance process.

Assessing Quality and Compatibility

Before purchasing any components, it’s crucial to evaluate their quality. Look for parts that meet or exceed original equipment manufacturer (OEM) standards. Additionally, compatibility with your specific model should be verified. Many reputable suppliers provide detailed specifications, making it easier to confirm that the part will fit seamlessly into your vehicle.

Choosing Reputable Suppliers

Identifying a reliable supplier is vital. Consider vendors that have a strong track record and positive customer feedback. Online reviews and forums can provide insight into the experiences of other vehicle owners. Moreover, local auto parts stores often offer personalized service and advice, which can be invaluable when seeking guidance on suitable components.

Investing time in finding high-quality replacement parts will not only enhance your vehicle’s performance but also contribute to your peace of mind while driving.