Understanding the upkeep of compact motorized vehicles is essential for optimal performance and longevity. This section will delve into various aspects of maintaining these machines, ensuring they remain in top condition. With proper care, users can enhance their riding experience while minimizing potential issues.

From troubleshooting common malfunctions to routine maintenance tasks, this guide provides valuable insights. Each component plays a crucial role in the overall functionality, and knowing how to address specific concerns can lead to more efficient operations. Whether you are a seasoned enthusiast or a newcomer, these tips aim to empower all users in their journey of ownership.

Additionally, this resource highlights the importance of using quality materials and following systematic approaches. By staying informed and proactive, individuals can avoid many pitfalls that may arise from neglect. Embrace the knowledge shared here to cultivate a deeper appreciation for your vehicle and its mechanics.

Vehicles in this category often encounter a variety of challenges that can affect their performance and reliability. Understanding these frequent problems can help users troubleshoot and maintain their units effectively.

Frequent Mechanical Concerns

One of the most common issues involves the engine not starting properly. This can be attributed to various factors such as fuel supply problems, ignition failures, or even battery issues. Ensuring each component is functioning correctly is essential for reliable operation.

Electrical System Malfunctions

Electrical failures are also prevalent, often manifesting as lighting issues or problems with the starting system. Regular checks of wiring connections and components can prevent these electrical setbacks.

| Issue | Possible Cause | Solution |

|---|---|---|

| Engine won’t start | Poor fuel flow | Check fuel lines and filter |

| Weak lighting | Faulty wiring | Inspect and repair connections |

| Battery draining quickly | Defective battery or charger | Replace or recharge battery |

Essential Tools for Repairs

Having the right instruments is crucial for ensuring effective maintenance and troubleshooting of your two-wheeled vehicle. A well-equipped toolkit not only facilitates smoother repairs but also enhances safety and efficiency during the process.

Basic Hand Tools

- Wrenches: A variety of sizes will help in loosening and tightening nuts and bolts.

- Screwdrivers: Both flathead and Phillips types are necessary for different fasteners.

- Pliers: Useful for gripping and bending wires and other components.

- Socket Set: Ideal for working with nuts in confined spaces.

Specialized Equipment

- Tire Pressure Gauge: Essential for checking the inflation of tires to ensure proper handling.

- Oil Filter Wrench: Helps in easily removing and replacing the oil filter.

- Multimeter: Useful for diagnosing electrical issues and testing circuits.

- Jack or Lift Stand: Provides stability and accessibility when working underneath the vehicle.

Step-by-Step Maintenance Guide

Proper upkeep of your two-wheeled vehicle is essential for ensuring its longevity and optimal performance. This section provides a comprehensive approach to maintaining your ride, focusing on key aspects that will enhance its functionality and safety.

| Task | Frequency | Description |

|---|---|---|

| Check Oil Level | Every 500 miles | Ensure the oil is at the recommended level to keep the engine lubricated. |

| Tire Inspection | Monthly | Examine tires for wear and maintain proper pressure for a safe ride. |

| Brake Check | Every 1000 miles | Inspect brake pads and fluid to guarantee reliable stopping power. |

| Battery Maintenance | Every 3 months | Check connections and charge level to ensure reliable starting. |

| Clean Air Filter | Every 2000 miles | Remove and clean to improve airflow and engine efficiency. |

Diagnosing Engine Problems

Identifying issues within a motor can be a challenging yet essential task for maintaining optimal performance. Understanding the symptoms and systematically evaluating the components can help uncover the root causes of malfunctioning mechanisms.

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| Engine won’t start | Insufficient fuel supply | Check fuel levels and lines |

| Unusual noises | Loose or damaged parts | Inspect components for wear |

| Loss of power | Clogged air filter | Replace or clean air filter |

| Overheating | Cooling system malfunction | Examine coolant levels and hoses |

Brake System Adjustments

Ensuring the optimal functioning of the braking system is crucial for safety and performance. Proper adjustments can enhance responsiveness and prolong the lifespan of brake components. This section outlines the essential steps and considerations for fine-tuning the brake mechanism effectively.

Checking Brake Components

Before making adjustments, it is vital to inspect the various components involved in the braking system. This includes:

- Brake pads or shoes for wear and damage

- Brake cables for fraying or corrosion

- Brake levers for smooth operation

Adjusting Brake Tension

Once the components are verified, you can proceed to adjust the brake tension. Follow these steps:

- Locate the adjustment barrel on the brake lever or the cable housing.

- Turn the barrel clockwise to increase tension, or counterclockwise to decrease it.

- Test the brake lever to ensure proper engagement and release.

Regular maintenance of these adjustments will help maintain safety and performance on the road.

Fuel System Cleaning Techniques

Maintaining a clean fuel system is essential for optimal performance and longevity of any small engine. Regular cleaning helps to eliminate deposits that can hinder fuel flow and affect combustion efficiency. This section explores various effective methods for cleaning the fuel system, ensuring your engine runs smoothly.

| Technique | Description | Benefits |

|---|---|---|

| Fuel Additives | Special chemical formulations designed to dissolve deposits and improve fuel quality. | Convenient and easy to use; helps maintain clean injectors. |

| Manual Cleaning | Disassembling components such as the carburetor for thorough cleaning with appropriate solvents. | Effective removal of stubborn deposits; restores optimal flow. |

| Ultrasonic Cleaning | Using ultrasonic waves in a cleaning solution to remove contaminants from intricate parts. | Reaches difficult areas; highly effective for precision cleaning. |

| Fuel System Flush | A process where a cleaning solution is run through the fuel lines to clear out contaminants. | Restores fuel flow; prevents future clogs. |

Replacing Spark Plugs Effectively

Changing ignition components is a crucial maintenance task that can significantly enhance engine performance. Ensuring these parts are in good condition contributes to smooth operation and efficiency.

To begin the replacement process, gather the necessary tools such as a socket wrench and a gap gauge. It’s essential to select the correct type of component compatible with your engine specifications.

First, make sure the engine is cool and disconnect the power source for safety. Remove the old ignition piece by loosening it carefully, avoiding any damage to surrounding components. Inspect the area for debris and clean it before inserting the new part.

Insert the new ignition component and tighten it securely, ensuring it is not overly tightened to prevent stripping. Finally, reconnect the power source and test the engine to confirm proper functionality.

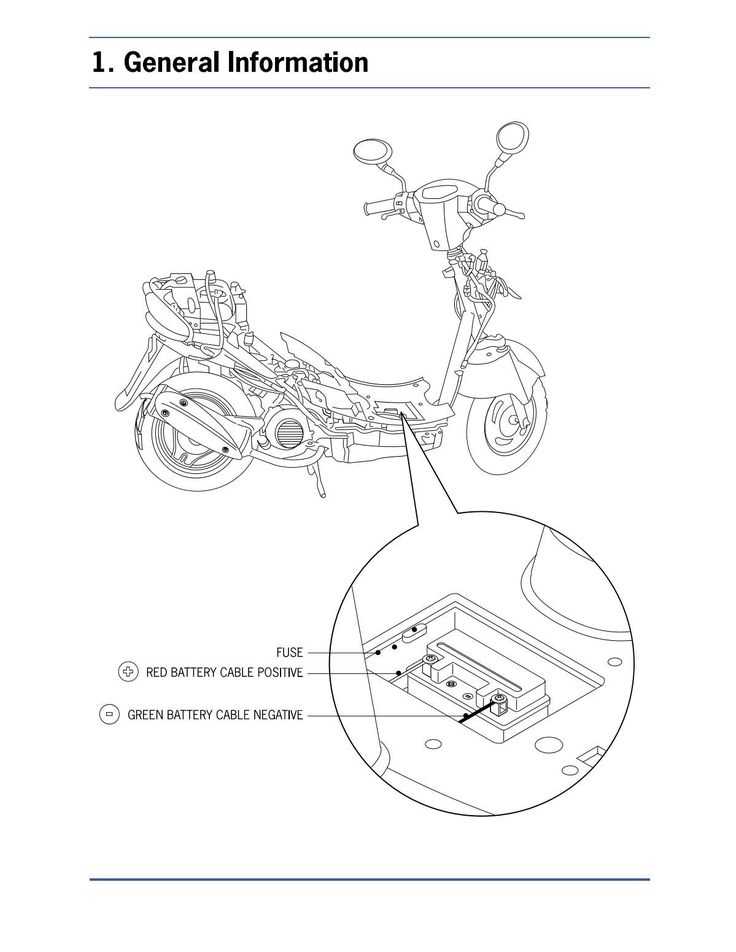

Battery Maintenance and Replacement

Maintaining the power source of your vehicle is essential for ensuring optimal performance and longevity. Regular checks and timely replacements can prevent unexpected failures and enhance the overall functionality.

Regular Inspection and Care

Routine examination of the power unit is crucial. Look for signs of corrosion, leaks, or loose connections. Keeping terminals clean and secure helps in maintaining a stable energy flow. Ensure that the fluid levels are adequate, as this contributes to the efficient operation of the power source.

Replacement Procedures

When it becomes necessary to substitute the power unit, follow proper protocols to ensure safety and efficiency. Disconnect the terminals before removal, starting with the negative side. Install the new unit by connecting the positive terminal first, followed by the negative. Ensure that all connections are tight to avoid future issues.

Checking and Adjusting Tire Pressure

Maintaining the correct air pressure in your vehicle’s tires is essential for ensuring optimal performance and safety. Proper inflation not only enhances handling and fuel efficiency but also prolongs the lifespan of the tires. Regularly checking and adjusting the tire pressure can prevent potential issues and improve overall riding comfort.

Importance of Correct Inflation

Inflated tires support the weight of the vehicle and ensure stable contact with the ground. Under-inflated tires can lead to excessive wear, reduced fuel efficiency, and compromised handling. Conversely, over-inflated tires may result in a harsh ride and increased risk of blowouts. Regular inspections are crucial for maintaining an ideal balance.

Steps to Check and Adjust Pressure

Begin by using a reliable tire pressure gauge to measure the current pressure. Compare this reading with the recommended specifications, usually found on a sticker inside the frame or in the owner’s guide. If the pressure is too low, add air until it reaches the optimal level. If it’s too high, gently release some air until the desired pressure is achieved. Repeat this process regularly to ensure consistent performance.

Transmission Troubleshooting Tips

Addressing issues within the transmission system can significantly enhance the overall performance of your vehicle. Understanding common symptoms and their causes is essential for effective diagnostics and resolution.

Common Symptoms of Transmission Issues

- Unusual noises during operation

- Slipping gears or difficulty shifting

- Fluid leaks under the vehicle

- Delayed acceleration or response

Diagnostic Steps

- Inspect fluid levels and quality.

- Check for visible leaks around the transmission.

- Examine the linkage and cables for proper adjustment.

- Listen for abnormal sounds while the engine is running.

By following these troubleshooting steps, you can identify and address transmission issues, ensuring a smoother and more reliable driving experience.

Understanding Electrical Components

Electrical systems play a crucial role in the functionality of various vehicles. A clear grasp of these elements can significantly enhance troubleshooting and maintenance efforts. This section explores key components that contribute to the overall electrical performance.

Key Electrical Elements

- Batteries: Serve as the primary power source, storing energy for starting and operating electrical systems.

- Wiring: Connects different components, allowing for the flow of electricity throughout the system.

- Fuses: Protect circuits by breaking the connection in case of overload, preventing damage to other parts.

- Switches: Control the flow of electricity, enabling or disabling various systems as needed.

- Relays: Act as electrically operated switches, allowing low-power signals to control high-power circuits.

Importance of Maintenance

Regular checks and maintenance of electrical components are essential for optimal performance. Neglecting these elements can lead to malfunctions and decreased efficiency. Consider the following practices:

- Inspect wiring for any signs of wear or damage.

- Ensure connections are secure to prevent power loss.

- Replace fuses promptly when they blow to avoid further complications.

- Test battery health regularly to ensure reliable performance.

Safety Precautions During Repairs

Ensuring a secure environment is essential when performing maintenance tasks on any vehicle. By adhering to certain guidelines, individuals can protect themselves and their surroundings from potential hazards that may arise during the process.

Wear Protective Gear: Always don suitable clothing, including gloves and safety glasses, to shield against harmful substances and debris. Proper footwear is also crucial to prevent slips and falls.

Work in a Ventilated Area: Ensure that the workspace is well-ventilated to avoid inhaling toxic fumes. Open windows or use exhaust fans to promote airflow, particularly when working with flammable materials.

Keep Tools Organized: Maintain a tidy workspace by organizing tools and equipment. This minimizes the risk of accidents and allows for efficient work without unnecessary distractions.

Disconnect Power Sources: Before starting any work, always disconnect the power supply to prevent accidental starts. This simple step can significantly reduce the likelihood of injury.

Follow Manufacturer Guidelines: Always consult relevant documentation for specific procedures and safety recommendations. Adhering to these instructions ensures the best practices are followed.