The world of agricultural equipment has evolved significantly, yet the importance of understanding the intricacies of machinery maintenance remains timeless. This section aims to provide valuable insights into the essential practices and techniques that can enhance the longevity and efficiency of farming tools. With a blend of historical context and practical advice, users can navigate the complexities of machinery upkeep with confidence.

Throughout the years, various resources have emerged, offering detailed instructions and troubleshooting tips for those looking to keep their equipment in optimal condition. Whether you are a seasoned farmer or a novice in the field, the ability to address common issues and perform regular upkeep is crucial. Emphasizing hands-on knowledge and accessibility, these resources serve as a bridge between past and present practices.

As we delve into the intricacies of machinery care, the focus will be on fostering a deeper understanding of operational protocols and maintenance routines. This exploration not only equips individuals with the necessary skills but also cultivates a greater appreciation for the craftsmanship behind these essential tools. Embracing this knowledge can lead to improved performance and a more sustainable approach to agricultural endeavors.

History of Chilton Tractors

The evolution of agricultural machinery has significantly influenced farming practices and productivity. One notable brand has played a pivotal role in this transformation, establishing a legacy that continues to resonate in the industry. This section delves into the origins, advancements, and impact of this renowned equipment over the years.

Origins and Development

The inception of this machinery dates back to a period of innovation in agriculture, where the need for efficient tools became paramount. Key milestones include:

- Initial designs focused on simplicity and reliability, catering to the demands of small and large-scale farmers alike.

- Improvements in engineering led to enhanced performance, enabling quicker fieldwork and reduced labor.

- The introduction of various models diversified options for users, addressing specific agricultural needs.

Impact on Agriculture

The influence of this equipment on farming practices is profound. Key contributions include:

- Significant increase in crop yields due to faster and more efficient land preparation.

- Reduction of physical strain on farmers, promoting better health and productivity.

- Facilitation of mechanization, leading to a shift in farming techniques and sustainability practices.

Through its enduring legacy, this brand has become synonymous with reliability and innovation, shaping the landscape of modern agriculture.

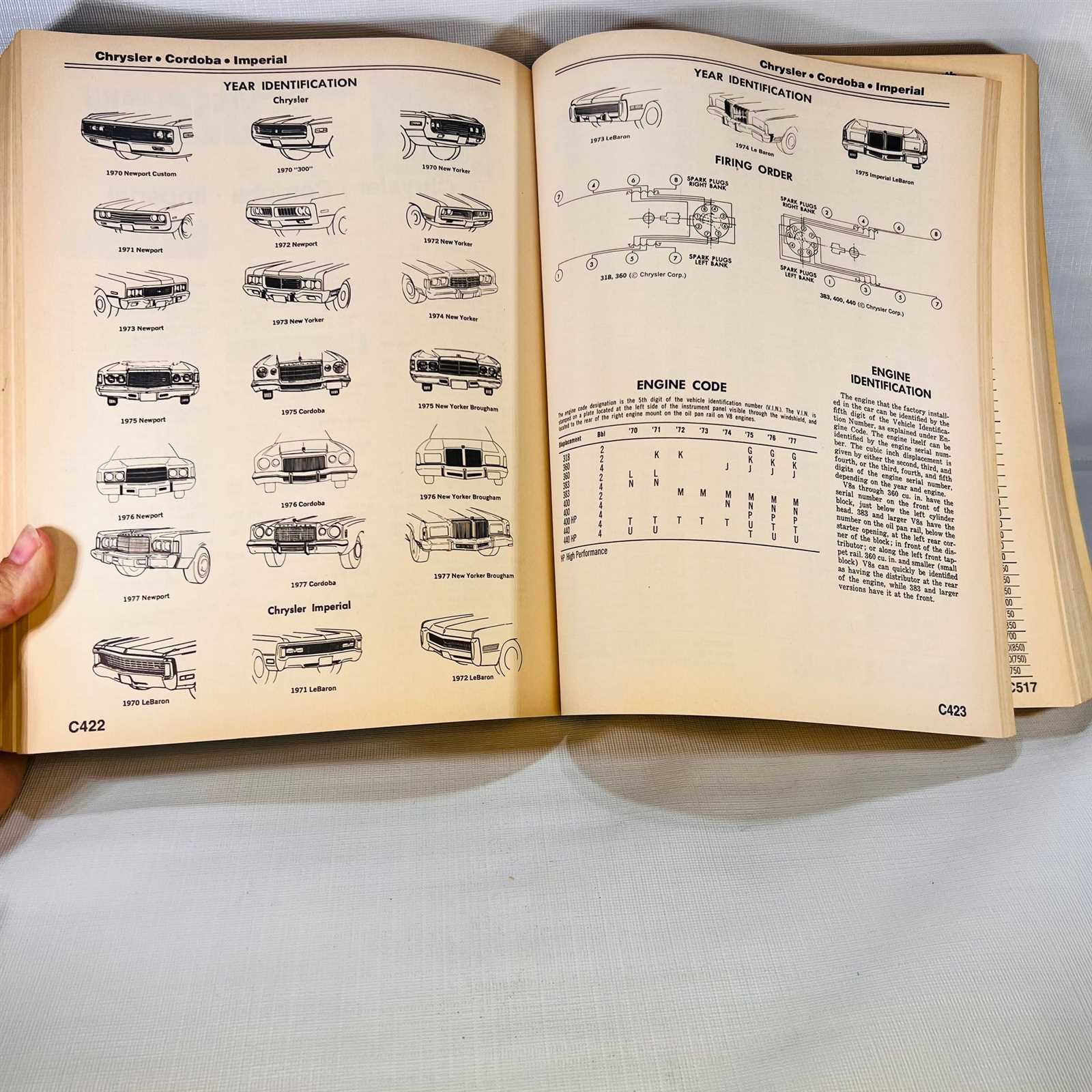

Key Features of 1800s Models

The machines from this era are remarkable for their innovation and engineering, showcasing a blend of functionality and design that transformed agricultural practices. Understanding their distinctive characteristics provides insight into the technological advancements of the time and their impact on farming efficiency.

Structural Design

The structural integrity of these models was paramount, ensuring durability and reliability in demanding conditions. Most were constructed using robust materials, which contributed to their longevity and effectiveness in various terrains.

Mechanical Components

Each unit featured unique mechanical components that enhanced their operational capabilities. Key elements included simplified gear systems and power take-offs that facilitated various agricultural tasks.

| Feature | Description |

|---|---|

| Material Quality | Heavy-duty metals and woods were commonly used, providing strength and resistance to wear. |

| Engine Type | Often powered by steam or early combustion engines, offering significant improvements in performance. |

| Functionality | Designed for multipurpose use, enabling tasks from plowing to hauling with ease. |

| Maintenance Accessibility | Components were generally easy to access, facilitating routine upkeep and repairs. |

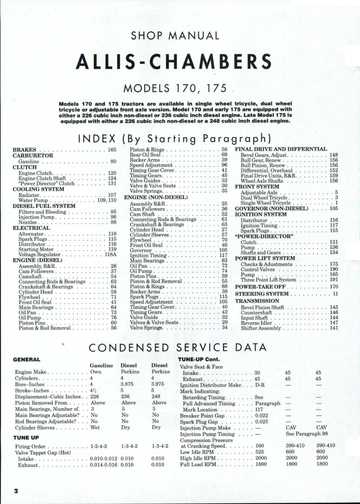

Common Repairs for Chilton Tractors

Maintaining agricultural machinery is essential for optimal performance and longevity. This section outlines frequent issues faced by operators and provides insights into necessary interventions to ensure smooth operation.

Frequent Issues Encountered

Operators often report several recurring problems, ranging from engine difficulties to hydraulic malfunctions. Addressing these concerns promptly can prevent further complications and enhance efficiency.

Basic Troubleshooting Steps

Identifying and resolving common challenges involves a systematic approach. Below is a table summarizing typical problems and their solutions:

| Problem | Symptoms | Suggested Solution |

|---|---|---|

| Engine Won’t Start | Clicking sound, no ignition | Check battery connections and replace the battery if necessary |

| Overheating | High temperature gauge, steam | Inspect coolant levels and radiator for blockages |

| Fluid Leaks | Puddles under machinery | Examine seals and gaskets; replace if damaged |

| Poor Hydraulic Performance | Sluggish movements, noise | Check hydraulic fluid levels and inspect hoses for wear |

Essential Tools for Tractor Maintenance

Proper upkeep of machinery requires a selection of fundamental instruments that ensure efficiency and longevity. Having the right equipment at hand not only facilitates routine checks but also enables timely interventions when issues arise. Understanding the necessary implements is crucial for anyone engaged in the upkeep of large agricultural machines.

Wrenches are indispensable for adjusting bolts and nuts. A complete set, including adjustable and socket varieties, allows for versatility in tackling different tasks. Additionally, screwdrivers of various types–both flathead and Phillips–are essential for fastening and unfastening components.

Pliers, particularly needle-nose and slip-joint, provide the grip needed for handling small parts and wires. For maintenance involving electrical systems, having a reliable set of wire strippers and crimpers is vital to ensure safe and effective connections.

Moreover, a good quality jack and jack stands are necessary for safely lifting and supporting heavy parts during inspection or repair. A comprehensive toolbox to keep everything organized enhances efficiency and accessibility.

Finally, investing in a multimeter allows for accurate diagnostics of electrical systems, ensuring any issues can be swiftly addressed. Equipping oneself with these essential tools lays a solid foundation for effective maintenance practices.

Step-by-Step Repair Instructions

This section provides a comprehensive guide to troubleshooting and restoring mechanical equipment effectively. By following a systematic approach, you can ensure that each component is thoroughly assessed and addressed.

- Assessment:

- Begin by identifying the symptoms of the issue.

- Take note of any unusual sounds or performance discrepancies.

- Inspect for visible damage or wear.

- Preparation:

- Gather necessary tools and replacement parts.

- Ensure a clean workspace to avoid contamination.

- Refer to technical specifications for guidance on components.

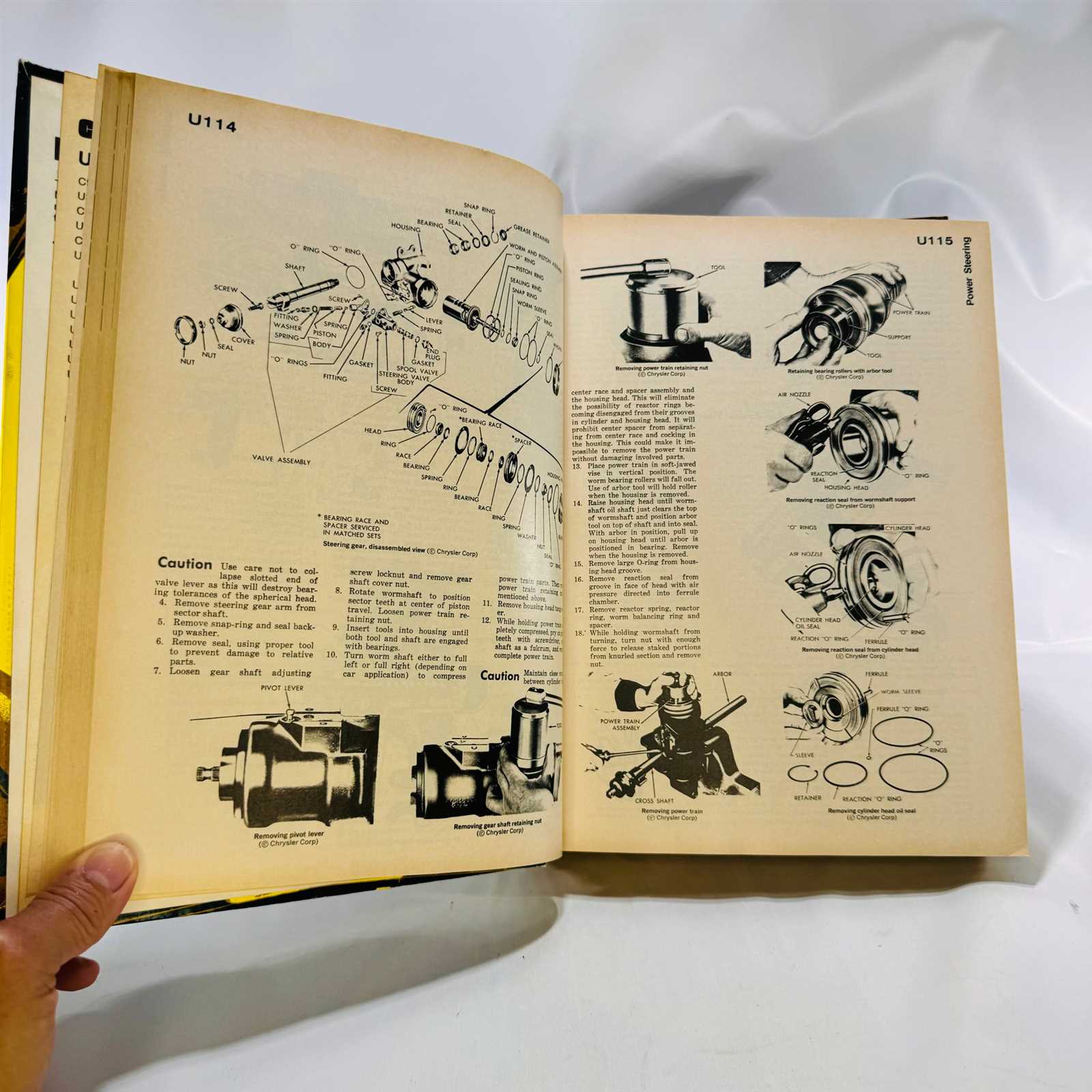

- Disassembly:

- Carefully remove any outer covers or panels.

- Label each part as you take it apart for easier reassembly.

- Take pictures if necessary to document the process.

- Inspection:

- Examine each component for signs of damage or malfunction.

- Check connections, seals, and moving parts for integrity.

- Test electrical systems for proper functioning.

- Replacement:

- Swap out any defective parts with new or refurbished items.

- Follow the specifications for installation procedures.

- Ensure all components are securely fastened and aligned.

- Reassembly:

- Put the equipment back together in the reverse order of disassembly.

- Double-check that all parts are properly connected.

- Ensure no tools or debris are left inside.

- Testing:

- Power on the equipment and monitor for any issues.

- Run through standard operational tests to verify functionality.

- Make adjustments as necessary based on performance.

By adhering to these structured guidelines, you can effectively restore the functionality of mechanical systems, ensuring they operate reliably for future use.

Diagnosing Mechanical Issues

Identifying problems in machinery requires a systematic approach that combines observation, testing, and experience. By carefully assessing the signs of malfunction, one can pinpoint the underlying causes and develop effective solutions.

Common Symptoms to Watch For

Pay attention to irregular noises, performance drops, and unexpected behavior during operation. Strange sounds, such as grinding or squeaking, often indicate wear or misalignment, while decreased efficiency may suggest issues with vital components.

Systematic Testing Methods

Implementing a step-by-step testing process is crucial. Start by checking fluid levels and connections, then proceed to evaluate electrical systems and moving parts. Each methodical check enhances the understanding of the machinery’s state and facilitates accurate troubleshooting.

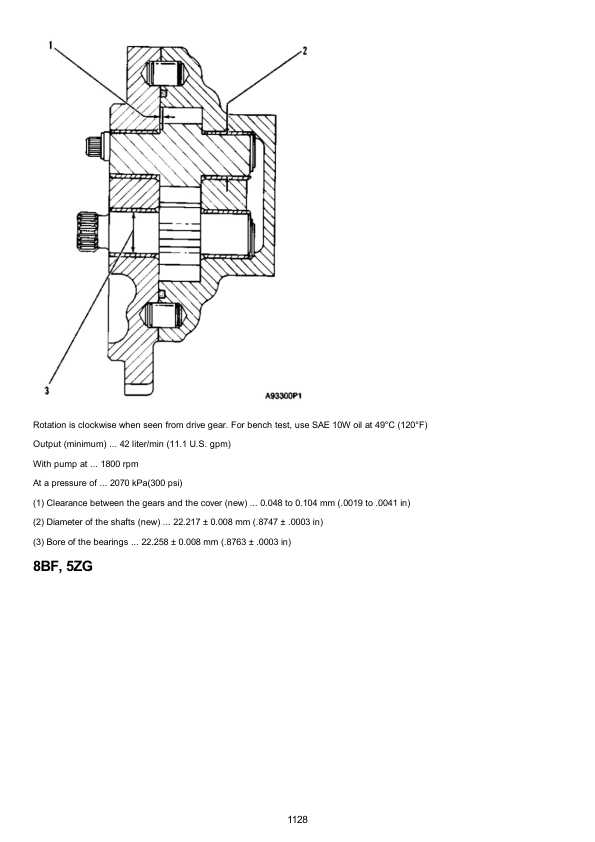

Understanding Engine Components

This section provides insights into the vital elements that contribute to the functionality of agricultural machinery. Grasping the intricacies of these components is essential for effective maintenance and optimal performance.

Key Elements of the Engine

- Cylinders: These chambers house the combustion process, driving the pistons.

- Pistons: They convert the energy from combustion into mechanical motion.

- Crankshaft: This component translates the linear motion of the pistons into rotational energy.

- Camshaft: It regulates the timing of the valve openings and closings, crucial for efficient airflow.

Supporting Systems

- Fuel System: Delivers the necessary fuel for combustion.

- Cooling System: Prevents overheating, maintaining optimal operating temperatures.

- Lubrication System: Reduces friction between moving parts, ensuring longevity.

Safety Practices During Repairs

Ensuring a secure environment while performing maintenance tasks is crucial for both personal well-being and effective operations. Adopting proper safety measures minimizes risks and enhances productivity, allowing individuals to focus on the task at hand without unnecessary distractions.

Personal Protective Equipment (PPE) plays a vital role in safeguarding against potential hazards. Always wear suitable gear, including gloves, goggles, and steel-toed boots, to protect against injuries from tools and equipment. Additionally, utilizing ear protection can prevent long-term hearing damage in noisy environments.

Before commencing any work, it is essential to assess the workspace. Ensure that the area is well-ventilated, organized, and free of clutter. Remove any obstacles that could pose a tripping hazard, and make sure that all tools and materials are within easy reach. This not only promotes efficiency but also reduces the likelihood of accidents.

Proper handling of tools and machinery cannot be overstated. Always follow the manufacturer’s instructions for usage, and keep equipment well-maintained to prevent malfunctions. When using power tools, double-check that safety guards are in place and functioning correctly. If working with hazardous substances, familiarize yourself with their safety data sheets and take appropriate precautions.

In case of an emergency, having a clear response plan is crucial. Ensure that a first aid kit is readily accessible and that individuals are aware of its location. Additionally, knowing the contact information for local emergency services can expedite response times if needed.

Lastly, encouraging open communication among team members enhances safety. Regularly discuss potential hazards and safety practices, fostering a culture of awareness and vigilance that benefits everyone involved.

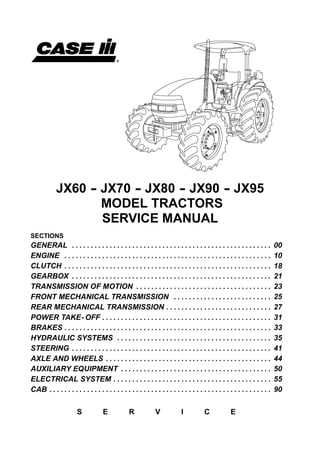

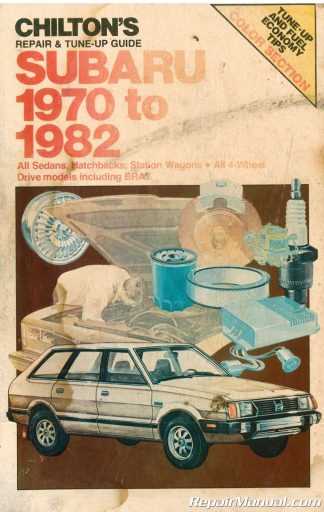

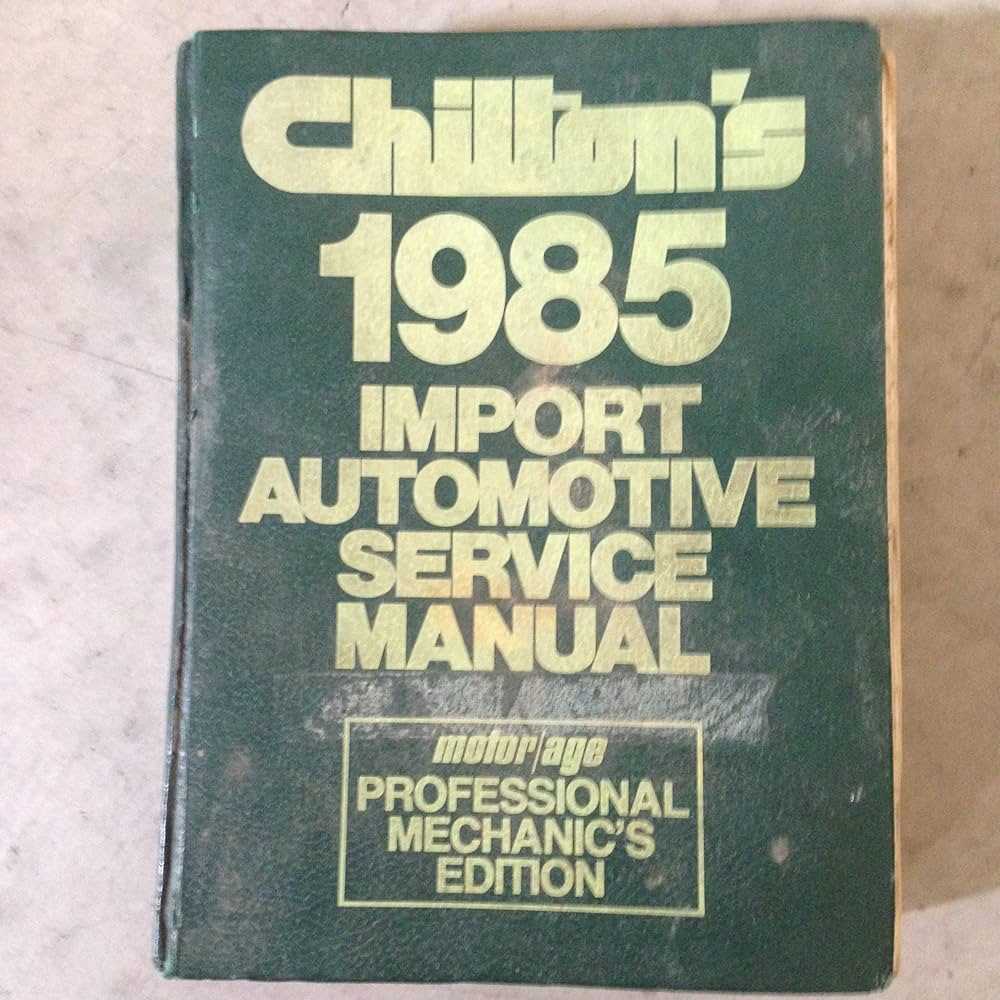

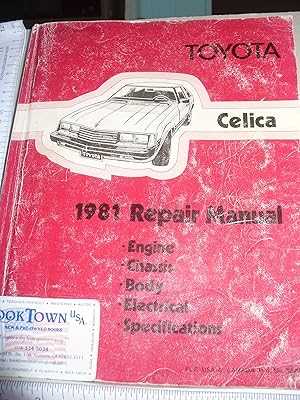

Finding Original Chilton Manuals

Locating authentic guides for vintage machinery can be a rewarding yet challenging endeavor. Collectors and enthusiasts often seek out these resources to ensure accurate information and preserve the history of their equipment. Various strategies and sources can assist in this pursuit, making the journey both enjoyable and fruitful.

Online Resources

Numerous websites specialize in vintage publications and often have a dedicated section for older guides. Auctions, marketplace platforms, and collector forums are valuable places to explore. Engaging with online communities can provide insights into where to find specific editions and rare copies.

Local Libraries and Archives

Many public libraries and archives maintain extensive collections of historical documents, including guides for machinery. Visiting local institutions can yield surprising discoveries, as some may house original editions that are not readily available elsewhere. Additionally, librarians can often assist in locating specific titles through interlibrary loans.

| Source Type | Potential Findings |

|---|---|

| Online Marketplaces | Reprints, used copies, and rare finds |

| Collector Forums | Tips, trades, and sales from fellow enthusiasts |

| Libraries | Original publications and archived editions |

| Antique Shops | Unique and unexpected resources |

Upgrading Parts for Improved Performance

Enhancing the functionality of agricultural machinery can significantly impact efficiency and productivity. By replacing or upgrading specific components, operators can achieve better performance and longevity. This section explores various modifications that can be made to achieve optimal results in the field.

One of the most effective ways to boost output is through the installation of high-quality engine components. Upgrading elements such as the air filter, fuel injectors, and exhaust systems can lead to improved combustion and overall power. Consider investing in parts designed for higher efficiency to maximize the potential of your machine.

In addition to engine improvements, transmission upgrades can facilitate smoother operation and better torque distribution. A more advanced gearbox can allow for enhanced speed control and adaptability to various terrains. This change not only optimizes performance but also reduces wear and tear on the machinery.

Don’t overlook the significance of suspension and tire enhancements. Opting for better-quality tires can improve traction and stability, while an upgraded suspension system can provide a smoother ride, reducing fatigue on both the operator and the equipment. These modifications can lead to increased efficiency in various working conditions.

Finally, regular maintenance and timely upgrades are crucial for maintaining peak performance. By routinely assessing and replacing worn components, operators can ensure their machinery remains reliable and effective. Investing in these enhancements not only improves functionality but also prolongs the lifespan of the equipment.

Restoration Techniques for Vintage Tractors

Restoring classic machinery is a rewarding endeavor that brings history back to life. The process involves a blend of art and science, requiring careful planning and attention to detail. Each project can vary significantly, but certain fundamental techniques can guide enthusiasts in their quest to revive these mechanical marvels.

One essential aspect of the restoration process is the assessment of the original components. Understanding which parts can be salvaged and which need replacement is crucial for maintaining authenticity. Often, this involves extensive research to source original or compatible parts that fit seamlessly into the overall design.

Another vital technique is surface preparation, which includes cleaning, sanding, and priming. This step not only enhances the aesthetic appeal but also protects against future deterioration. The choice of coatings and finishes can greatly influence the final appearance and longevity of the restored piece.

| Technique | Description |

|---|---|

| Assessment | Evaluate original components for salvageability and sourcing replacements. |

| Surface Preparation | Clean, sand, and prime to enhance aesthetics and prevent corrosion. |

| Mechanical Overhaul | Inspect and repair engines, transmissions, and other vital systems. |

| Finishing Touches | Apply appropriate coatings to ensure durability and visual appeal. |

Finally, completing a restoration often involves a series of finishing touches that highlight the unique character of the equipment. These enhancements, while seemingly minor, can make a significant difference in the overall presentation and functionality. Through dedication and skill, vintage machinery can be transformed into stunning displays of craftsmanship and engineering heritage.

Community Resources and Support

Access to local knowledge and assistance is vital for individuals engaged in mechanical restoration and maintenance. Communities often band together to share expertise, tools, and resources, fostering a culture of collaboration and learning. This network can be invaluable for troubleshooting and problem-solving.

Workshops and Training Sessions provide hands-on opportunities to enhance skills and learn from experienced practitioners. These events can cover various topics, from basic upkeep to advanced techniques, ensuring participants gain practical insights.

Online Forums and Groups have become popular venues for discussion and advice. Enthusiasts from different backgrounds can exchange tips, share successes, and ask questions, creating a rich repository of information accessible to all.

Local Clubs and Associations often organize meetups and events, encouraging members to share their experiences and techniques. Being part of such groups can lead to lifelong friendships and a deeper understanding of the craft.

Finally, Resource Libraries can serve as valuable repositories of information, housing books, manuals, and reference materials that are essential for both novices and seasoned professionals. Accessing these materials can empower individuals to tackle projects with confidence.