In the world of machinery, understanding how to maintain and troubleshoot your equipment is crucial for ensuring longevity and optimal performance. Whether you are a seasoned professional or a casual user, having access to detailed guidance can make all the difference when facing operational challenges. This section aims to provide essential insights and instructions tailored to help you navigate common issues effectively.

From basic upkeep to more intricate problem-solving techniques, the information compiled here is designed to empower you with the knowledge necessary to handle various situations. You will discover useful tips, step-by-step processes, and advice on what to do when things don’t go as planned. Having a clear understanding of your tools and their maintenance can prevent costly repairs and downtime.

By familiarizing yourself with these resources, you will enhance your skills and confidence in managing your equipment. Each aspect covered is crafted to help you achieve a smoother operation and extend the lifespan of your devices. Dive into this guide to unlock the full potential of your machinery and ensure it runs seamlessly for years to come.

Understanding Campbell Hausfeld Products

When it comes to tools and equipment designed for both home and professional use, one brand stands out for its reliability and versatility. Their extensive range of products caters to various needs, from simple household tasks to more complex industrial applications. By grasping the features and functionalities of these offerings, users can make informed choices that enhance their efficiency and productivity.

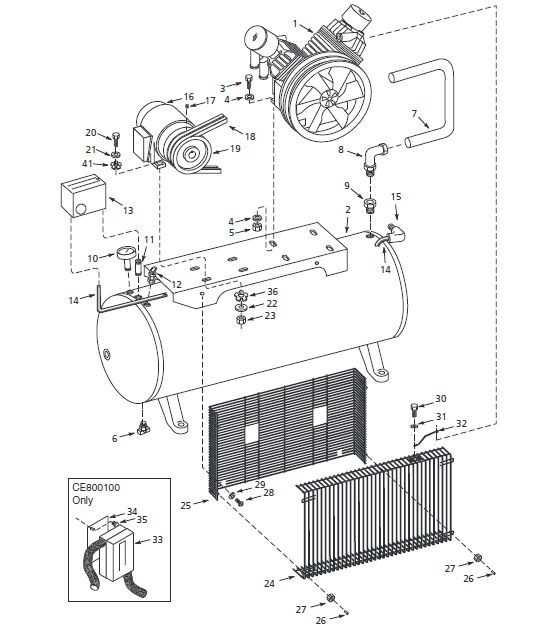

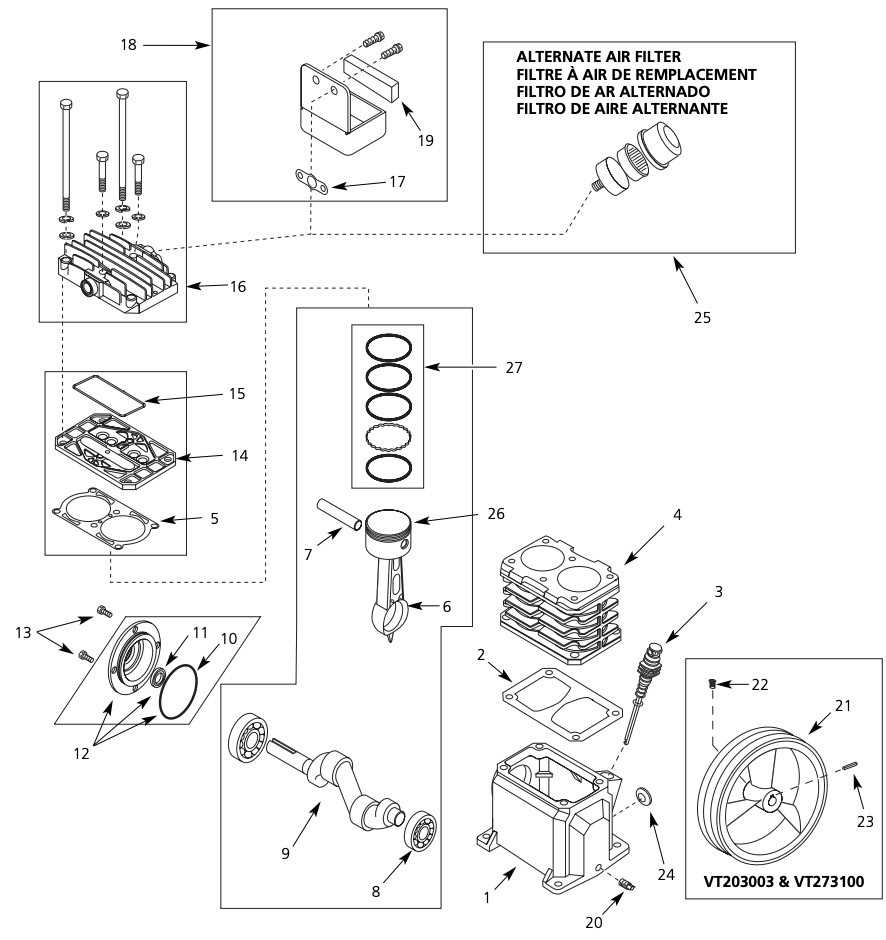

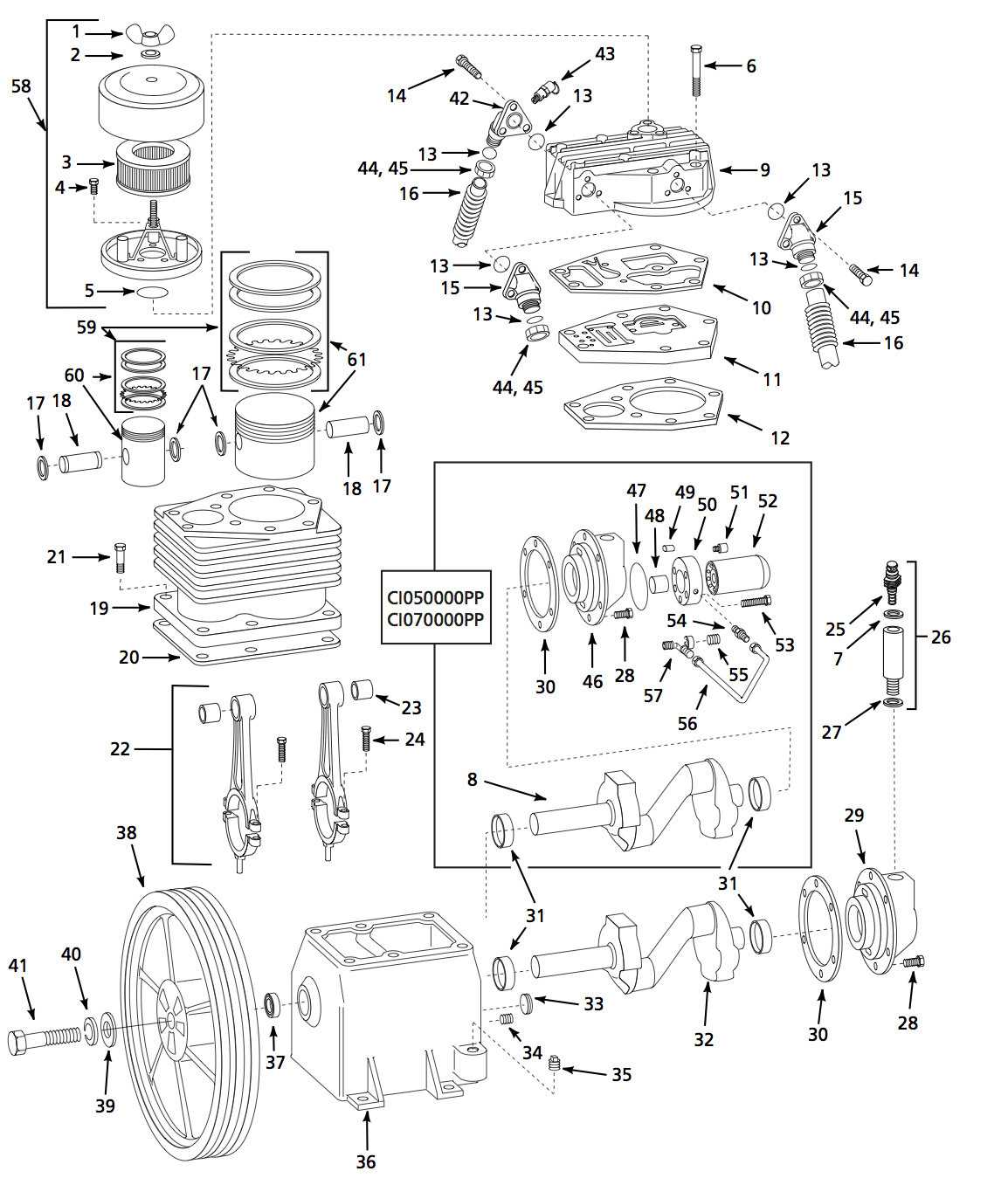

Quality and Innovation are at the core of this brand’s philosophy. Each product is engineered to meet high standards, ensuring durability and performance. Whether it’s pneumatic tools, air compressors, or pressure washers, users can expect innovations that simplify tasks and deliver impressive results.

Understanding the specific features of these tools is crucial for optimal use. From varying power levels to unique attachments, familiarizing oneself with these elements allows for a tailored approach to projects. This knowledge not only maximizes the effectiveness of the tools but also extends their lifespan, making them valuable investments.

Ultimately, recognizing the range of products available enables users to select the right tools for their specific needs, ensuring that every task can be tackled with confidence and efficiency.

Common Issues with Campbell Hausfeld Equipment

When working with various tools and machinery, users often encounter a range of recurring problems that can affect performance and efficiency. Identifying these issues early on can save time and resources, ensuring that equipment remains in optimal working condition.

One frequent concern is air leaks, which can lead to decreased pressure and overall effectiveness. Such leaks often occur in hoses or fittings and may require thorough inspection to locate and resolve.

Noise levels can also be a significant indicator of underlying issues. Excessive sounds may suggest mechanical wear or misalignment, prompting the need for adjustments or component replacement.

Another common problem is inconsistent power output. This can result from a variety of factors, including inadequate maintenance or electrical issues. Regular checks on connections and the power source can mitigate these challenges.

Finally, overheating is a prevalent issue that can arise from prolonged use or insufficient cooling mechanisms. Ensuring proper airflow and routine cleaning can help prevent this from occurring.

How to Access Repair Manuals Online

Finding technical documentation for various equipment can significantly ease the troubleshooting and maintenance processes. Fortunately, numerous online resources are available that provide comprehensive guides and instructions for various models and brands. This section outlines the best methods to locate these valuable resources effectively.

Utilizing Manufacturer Websites

One of the most reliable sources for technical documentation is the official website of the manufacturer. Follow these steps to navigate effectively:

- Visit the manufacturer’s official website.

- Locate the support or resources section.

- Search for your specific model using its identification number.

- Download the available documentation in PDF or other formats.

Exploring Online Forums and Communities

Another great way to find helpful resources is through online forums and user communities. These platforms often contain user-generated content, including shared guides and tips:

- Join relevant forums dedicated to your equipment type.

- Use the search function to find discussions related to your model.

- Post questions if you can’t find the information you need; community members are often willing to help.

By leveraging these methods, you can access the necessary documentation to ensure your equipment operates efficiently and effectively.

Essential Tools for Effective Repairs

To achieve optimal outcomes in any maintenance task, having the right instruments at hand is crucial. These items not only facilitate smooth operations but also enhance efficiency, allowing for a seamless workflow. Whether you are a seasoned expert or a novice, understanding which tools to utilize can significantly impact the success of your projects.

Basic Equipment

- Wrenches: Versatile for loosening and tightening various fasteners.

- Screwdrivers: Essential for handling screws of different sizes and types.

- Pliers: Useful for gripping, twisting, and cutting materials.

- Hammer: Perfect for driving nails or breaking apart objects.

- Measuring tape: Ensures precise measurements for accurate fitting.

Advanced Instruments

- Multimeter: Vital for electrical diagnostics and troubleshooting.

- Socket set: Provides a range of sizes for various nuts and bolts.

- Torque wrench: Ensures proper tightening to avoid damage.

- Heat gun: Effective for shrinking, bending, or removing materials.

- Level: Guarantees surfaces are straight and properly aligned.

By assembling a comprehensive collection of these tools, you empower yourself to tackle a wide variety of tasks with confidence and skill.

Step-by-Step Guide to Troubleshooting

This section provides a systematic approach to identifying and resolving common issues that may arise during the operation of various tools. By following a structured method, users can efficiently diagnose problems and implement effective solutions.

Common Issues and Solutions

| Issue | Possible Cause | Solution |

|---|---|---|

| No Power | Faulty connection | Check all power connections and ensure the outlet is functional. |

| Low Pressure | Blocked hose | Inspect and clear any obstructions in the hose. |

| Excessive Noise | Worn bearings | Lubricate moving parts or replace bearings if necessary. |

Final Steps

If issues persist after following these steps, consult the manufacturer for further assistance. Understanding the underlying mechanisms can lead to the ultimate resolution of problems encountered.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your equipment involves consistent care and attention to detail. Proper upkeep not only enhances performance but also prevents premature wear and tear. Below are some essential practices that can help maintain optimal functionality over time.

Regular Inspection

Routine checks can identify potential issues before they escalate. Look for signs of damage or wear, and address them promptly to avoid more significant problems later.

Cleaning and Lubrication

Keeping components clean is crucial for smooth operation. Dust and debris can lead to overheating and malfunction. Additionally, applying the right lubricant can reduce friction and wear on moving parts.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Visual Inspection | Monthly | Check for any visible wear or damage. |

| Deep Cleaning | Every 6 Months | Remove dust and debris from all surfaces. |

| Lubrication | Quarterly | Apply lubricant to all moving parts. |

| Parts Replacement | As Needed | Replace worn or damaged components immediately. |

Safety Precautions During Repairs

When engaging in maintenance or troubleshooting tasks, it is crucial to prioritize safety to prevent accidents and injuries. Adhering to specific guidelines can significantly reduce risks and ensure a smooth working process. This section highlights essential safety measures to follow while conducting any form of technical work.

Before beginning any task, it is essential to gather the right tools and protective gear. Using appropriate equipment not only enhances efficiency but also minimizes the likelihood of mishaps. Always ensure that the workspace is clean and well-organized, which helps in avoiding unnecessary hazards.

| Safety Measure | Description |

|---|---|

| Wear Protective Gear | Utilize safety goggles, gloves, and masks to shield against debris and harmful substances. |

| Disconnect Power Sources | Always unplug equipment or turn off power to prevent electrical shock during the process. |

| Keep Workspace Organized | A tidy area reduces the risk of tripping or misplacing tools, enhancing overall safety. |

| Read Instructions Carefully | Thoroughly understanding guidelines helps avoid errors that could lead to accidents. |

| Have a First Aid Kit Available | Being prepared for minor injuries can mitigate risks and provide immediate assistance if needed. |

By following these fundamental precautions, individuals can create a safer environment, enabling them to focus on their tasks without undue concern for their well-being. Safety should always be a priority in any technical endeavor.

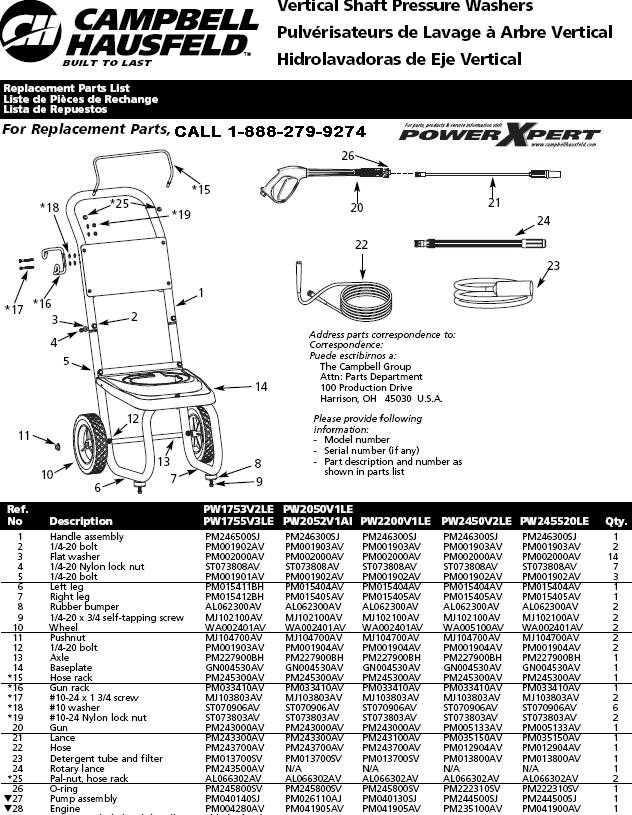

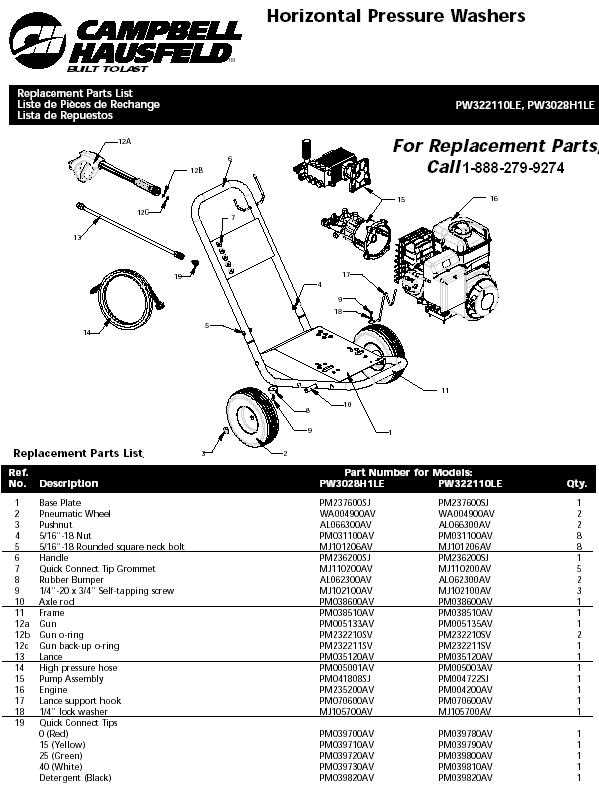

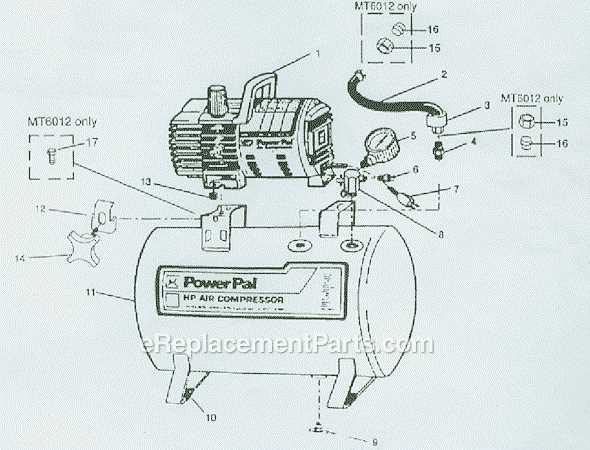

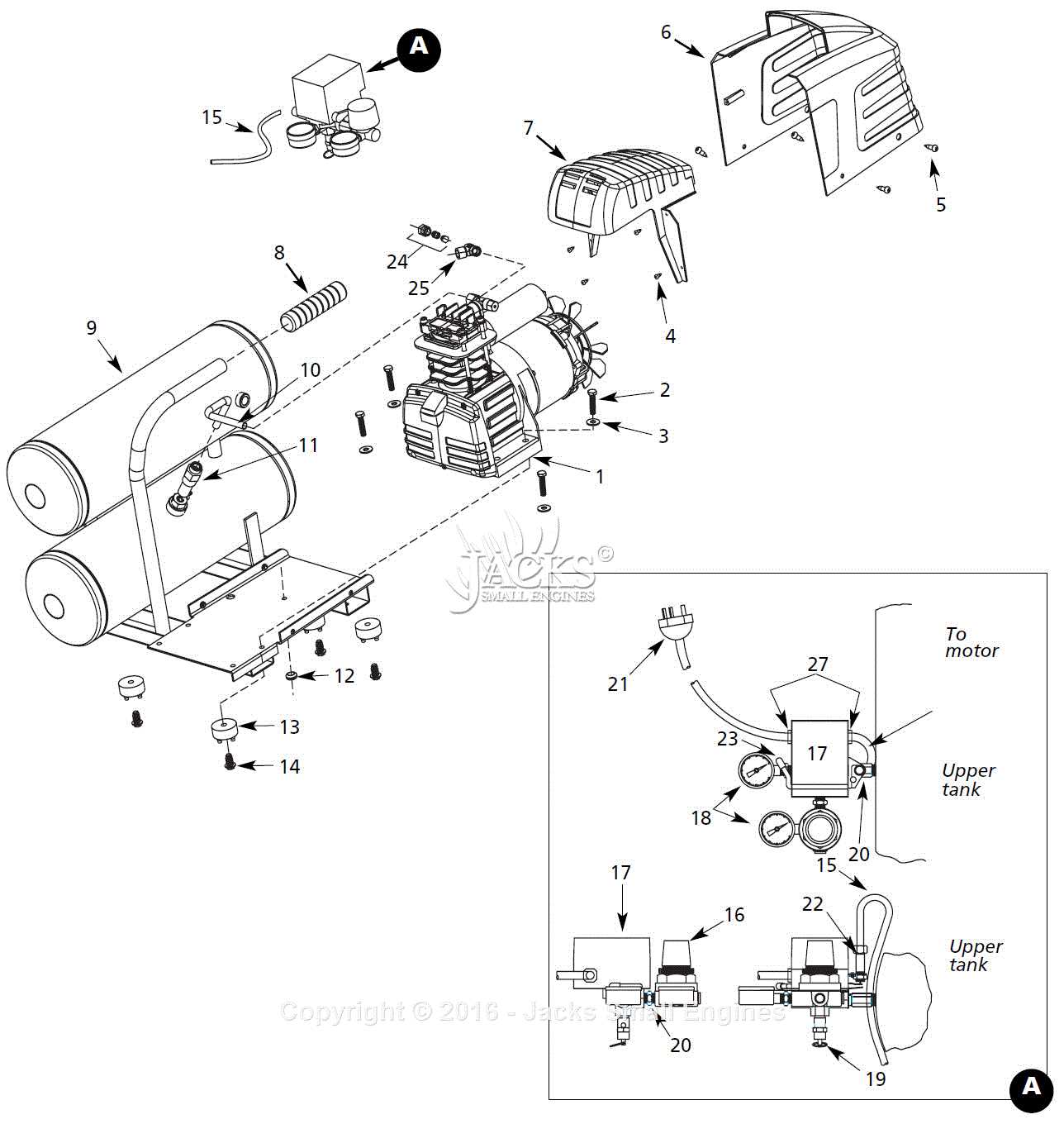

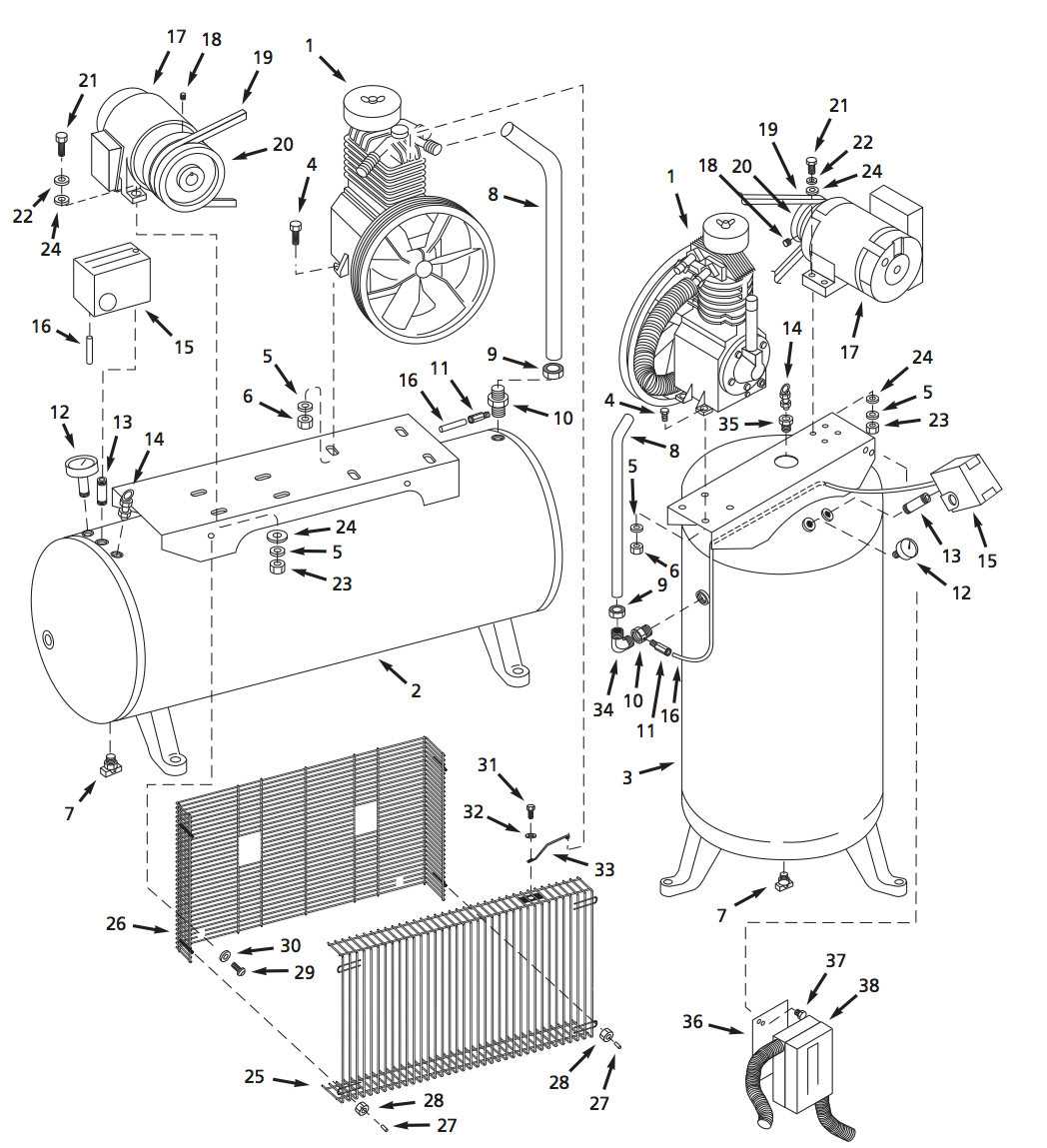

Replacement Parts: Where to Find Them

When it comes to maintaining and restoring your equipment, sourcing the right components is essential for optimal performance. Whether you’re dealing with a malfunction or simply upgrading, knowing where to locate these parts can save time and money.

One of the most reliable places to start your search is the official website of the manufacturer. Here, you can often find a comprehensive catalog of available components, along with detailed descriptions and specifications. Additionally, authorized dealers provide a trustworthy source, ensuring that you receive genuine items that meet quality standards.

Another option is online marketplaces that specialize in hardware and equipment parts. Websites like eBay or Amazon can offer a variety of options, but it’s crucial to verify the seller’s reputation and product reviews to avoid counterfeit items.

Don’t overlook local retailers and hardware stores; many carry popular components that can be purchased immediately. Furthermore, specialized repair shops often have valuable resources and may even stock hard-to-find items.

For those seeking a broader range of choices, consider joining online forums and communities dedicated to equipment enthusiasts. Members frequently share sources and experiences, which can lead you to the best deals and alternatives.

In summary, whether you opt for official channels or explore third-party options, taking the time to research and compare can ensure you find the parts you need for your projects.

DIY vs. Professional Repairs: Pros and Cons

The decision between tackling a project on your own or enlisting the help of a specialist is one many face. Each option has its advantages and disadvantages, influencing both the outcome and the overall experience. Understanding these factors can help in making an informed choice that aligns with your skills, budget, and time constraints.

Advantages of DIY Approach

Taking matters into your own hands can be rewarding. Firstly, it often leads to significant savings as you avoid labor costs. Additionally, engaging in a project yourself can enhance your skills and knowledge, providing a sense of accomplishment. Flexibility is another key benefit; you can work at your own pace and schedule, making adjustments as needed without coordinating with others.

Drawbacks of DIY Approach

However, the do-it-yourself method is not without its challenges. The initial investment in tools and materials can add up, and time spent on the task may exceed expectations. There is also the risk of making mistakes that could lead to further issues, potentially resulting in higher costs for corrections. In some cases, a lack of expertise can compromise safety and effectiveness.

User Reviews: Real-World Experiences

This section explores firsthand accounts from users who have interacted with various products and tools. By sharing their insights, individuals provide a clearer picture of performance, reliability, and satisfaction. Such experiences can guide potential buyers in making informed decisions based on real-life usage rather than theoretical specifications.

Positive Feedback: Many users appreciate the ease of operation and durability of their tools. One reviewer mentioned, “I’ve had mine for years, and it’s still going strong. It handles tough tasks with ease, making my projects much smoother.” This sentiment echoes a common theme among users who value longevity and reliability in their equipment.

Constructive Criticism: Conversely, some feedback highlights areas for improvement. A user noted, “While it works well, the noise level is a bit high for my liking. I often have to wear ear protection during use.” Such critiques can be invaluable for manufacturers looking to enhance their offerings and for new users weighing their options.

In summary, real-world experiences shed light on both the strengths and weaknesses of various tools, helping consumers navigate their choices more effectively.

Upgrading Your Campbell Hausfeld Tools

Improving your equipment can significantly enhance performance and efficiency. Whether you’re a professional tradesperson or a DIY enthusiast, exploring advancements and enhancements for your tools can lead to better results and greater satisfaction in your projects.

Benefits of Upgrading

- Increased Efficiency: Newer models often come with improved technology, making tasks quicker and easier.

- Enhanced Features: Upgraded tools may include additional functionalities that streamline your workflow.

- Improved Durability: Modern designs often use superior materials, increasing the lifespan of your equipment.

- Better Precision: Enhanced engineering can lead to more accurate results in your work.

How to Choose the Right Upgrades

- Assess your current tools and identify areas for improvement.

- Research newer models and their features to find what suits your needs.

- Consider compatibility with existing equipment before making a purchase.

- Read reviews and seek recommendations from other users for insights.

By thoughtfully selecting upgrades, you can elevate your performance and achieve superior results in all your endeavors.