In the realm of construction and agricultural machinery, understanding the intricacies of maintenance is essential for ensuring optimal performance and longevity. This segment focuses on the comprehensive approach to keeping these versatile machines in peak condition, emphasizing the importance of regular upkeep and timely interventions.

Having a reliable source of information at your disposal can significantly streamline the troubleshooting process and empower operators to tackle issues effectively. By delving into the specifics of each component, users can gain a clearer perspective on how to address common challenges, thereby enhancing both efficiency and safety in their operations.

Moreover, being well-versed in the operational guidelines not only facilitates smoother functioning but also aids in preventing costly breakdowns. This guide serves as a vital resource for anyone looking to maintain their equipment with confidence, ensuring that every task can be accomplished with precision and ease.

Understanding Gehl Skid Steers

Compact loaders are versatile machines designed for a variety of tasks in construction, landscaping, and agriculture. Their ability to maneuver in tight spaces while offering powerful lifting capabilities makes them invaluable on job sites. Knowing the fundamental aspects of these machines can enhance their efficiency and prolong their lifespan.

Key Features and Advantages

These loaders typically come equipped with a range of features that improve their functionality. Enhanced visibility and operator comfort are crucial, as they allow for safer operation. Many models also offer interchangeable attachments, increasing their utility for diverse applications, from digging to lifting.

Maintenance Tips

Regular maintenance is essential to ensure optimal performance. Routine checks of fluid levels, filters, and wear components can prevent costly breakdowns. Staying informed about common issues and knowing how to address them will keep these machines running smoothly for years to come.

Common Issues with Skid Steers

Operating compact construction machinery can often lead to a range of challenges that operators may encounter during their tasks. Understanding these common problems is essential for maintaining efficiency and ensuring safety on the job site.

| Issue | Description | Possible Solution |

|---|---|---|

| Hydraulic System Failure | Loss of power or responsiveness in hydraulic functions. | Check fluid levels and inspect hoses for leaks. |

| Engine Overheating | Excessive temperature leading to performance issues. | Inspect cooling system components and ensure proper airflow. |

| Electrical Problems | Malfunctions in the electrical system affecting operation. | Examine wiring and connections for wear or damage. |

| Track Wear | Degradation of tracks impacting mobility and stability. | Regularly inspect and replace worn tracks as necessary. |

| Excessive Vibration | Unusual shaking during operation indicating potential issues. | Check for loose components and ensure proper maintenance of parts. |

Essential Tools for Repairs

When tackling machinery maintenance, having the right instruments at your disposal is crucial for achieving effective results. A well-equipped toolkit not only streamlines the process but also enhances safety and precision during each task. Understanding the fundamental tools required for service work can significantly improve your efficiency and confidence in handling various issues.

First and foremost, a comprehensive set of hand tools is indispensable. Wrenches, sockets, and pliers are essential for loosening and tightening fasteners, while screwdrivers of various types facilitate the assembly and disassembly of components. A high-quality ratchet and extension set allows for better access in confined spaces, making your efforts more effective.

In addition to hand tools, power tools play a vital role in modern maintenance tasks. Impact wrenches, drills, and grinders can save considerable time and effort, particularly when dealing with stubborn parts or extensive repairs. Ensuring that your power tools are in good working order and appropriate for the tasks at hand is paramount for optimal performance.

Safety equipment should never be overlooked. Gloves, goggles, and hearing protection are essential to safeguard against injuries while working. A well-ventilated workspace and appropriate clothing also contribute to a safer environment, allowing you to focus on the task without distraction.

Lastly, having diagnostic tools on hand, such as multimeters and pressure gauges, can provide invaluable insights into the condition of various systems. These devices help identify underlying issues that may not be immediately visible, ensuring that repairs are both thorough and effective.

Step-by-Step Maintenance Guide

Regular upkeep is essential for ensuring the longevity and optimal performance of your machinery. Following a structured maintenance routine not only enhances efficiency but also helps in preventing unexpected breakdowns. This guide will provide you with clear steps to maintain your equipment effectively.

Begin by reviewing the operator’s documentation to familiarize yourself with specific requirements. Create a maintenance schedule that outlines key tasks such as checking fluid levels, inspecting filters, and examining belts and hoses. Consistency is key; set reminders to keep track of when tasks are due.

Start each session with a thorough inspection. Look for signs of wear or damage, paying close attention to critical components. Clean any debris from the machinery to prevent overheating and ensure proper functioning. Regularly replace worn parts and fluids to maintain peak performance.

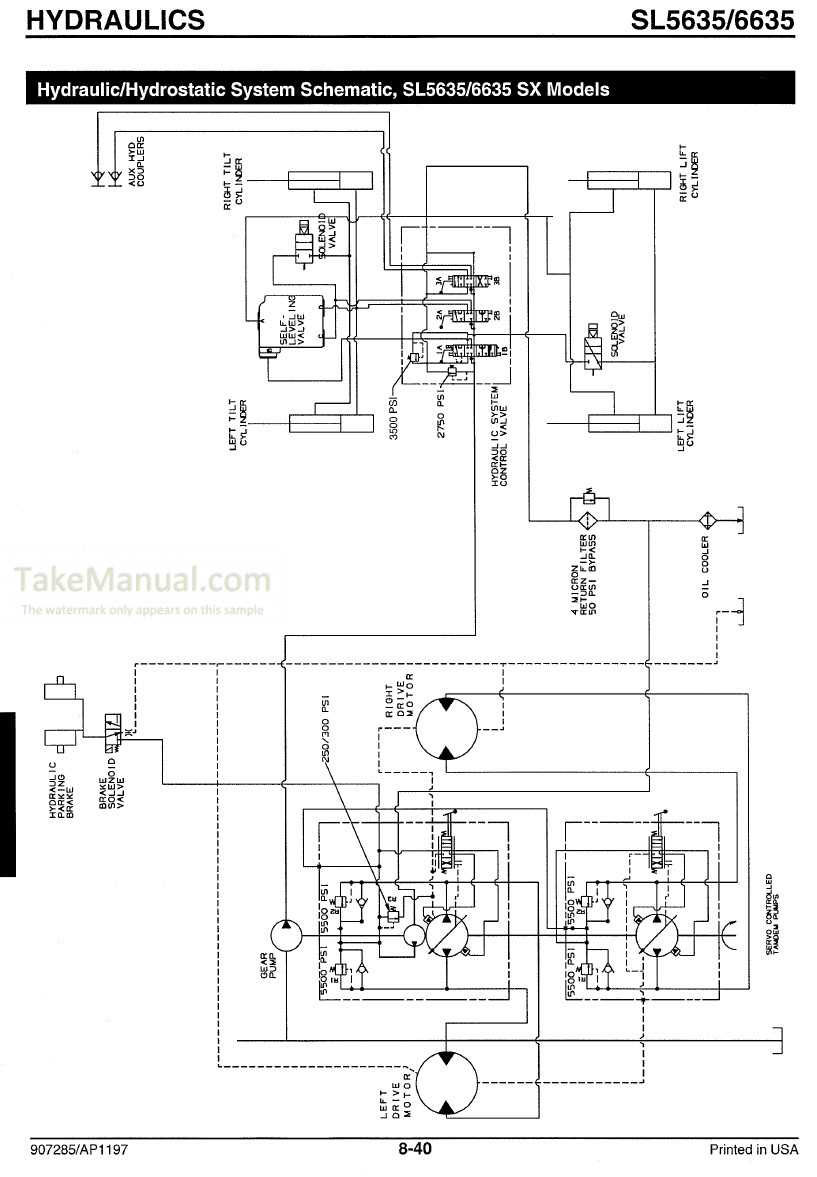

Next, conduct routine checks on hydraulic systems. Inspect hoses for leaks and ensure connections are secure. Proper fluid levels are crucial; top off as necessary and replace the fluid based on the manufacturer’s recommendations.

Don’t forget about the electrical system. Test the battery and clean terminals to prevent corrosion. Check all lights and signals to ensure they are functioning correctly, as visibility is vital for safe operation.

Finally, document all maintenance activities. Keeping accurate records will help track the history of your equipment, making it easier to identify recurring issues and plan for future servicing needs.

Identifying Hydraulic Problems

Understanding hydraulic issues is crucial for maintaining optimal performance in machinery. These problems often manifest through various symptoms, making it essential to recognize the signs early to avoid extensive damage.

Common Indicators: Look for unusual noises, such as grinding or whining, which may suggest low fluid levels or air in the system. Additionally, erratic movements or lack of response from hydraulic components can signal underlying issues.

Fluid Quality: Inspect the hydraulic fluid regularly. Contamination, discoloration, or a burnt smell indicates the need for replacement. Maintaining clean fluid is key to preventing component wear and ensuring smooth operation.

Pressure Testing: Conducting pressure tests can help identify leaks or blockages. If the system fails to reach specified pressure levels, this may point to malfunctioning valves or pumps that require further investigation.

Timely diagnosis and intervention can extend the life of hydraulic systems, ensuring reliable functionality and efficiency.

Engine Troubleshooting Techniques

Identifying issues within a power unit is crucial for maintaining optimal performance. Proper diagnostics can help prevent extensive damage and ensure efficient operation. Understanding the common signs of malfunction is the first step toward effective resolution.

Common Symptoms of Engine Issues

- Unusual noises, such as knocking or rattling

- Excessive smoke or unusual exhaust color

- Poor acceleration or sluggish performance

- Difficulty starting or stalling during operation

- Fluid leaks beneath the machine

Troubleshooting Steps

- Begin with a visual inspection for obvious signs of wear or damage.

- Check fluid levels and conditions, including oil, coolant, and fuel.

- Inspect filters for clogs and replace them as necessary.

- Test battery voltage and connections to ensure proper electrical flow.

- Run diagnostic tests using appropriate tools to identify error codes.

By following these techniques, operators can systematically address and resolve power unit issues, leading to improved reliability and longevity.

Electrical System Diagnostics

The electrical system in machinery plays a critical role in ensuring optimal performance and reliability. Proper diagnostics are essential for identifying issues that may affect functionality and safety. This section focuses on the key aspects of troubleshooting electrical components, emphasizing the importance of systematic analysis and methodical approaches.

Identifying Symptoms is the first step in the diagnostic process. Common indicators of electrical problems include erratic behavior, failure to start, or malfunctioning controls. Observing these signs helps in narrowing down potential issues.

Next, visual inspections are crucial. Check for loose connections, damaged wires, or corroded terminals. A thorough examination can reveal immediate problems that require attention before proceeding with more complex diagnostics.

Utilizing diagnostic tools, such as multimeters and circuit testers, allows for detailed analysis of electrical circuits. Measuring voltage, current, and resistance can provide insight into the functionality of components and help locate faults.

In cases where the issue persists, consulting wiring diagrams and schematics can guide the troubleshooting process. Understanding the electrical layout of the system aids in tracking down the source of malfunctions and facilitates effective repairs.

Lastly, testing individual components is often necessary. Isolating and evaluating parts like relays, sensors, and batteries ensures that each element functions correctly within the system. This methodical approach minimizes downtime and enhances overall efficiency.

Transmission and Drive Repairs

This section focuses on the maintenance and troubleshooting of the transmission and drive systems essential for optimal performance. Proper understanding of these components ensures reliability and efficiency in operation.

Common Issues

Frequent problems that may arise include fluid leaks, overheating, and irregular shifting. Identifying these issues early can prevent more severe damage and costly downtime.

Maintenance Tips

Regular checks and servicing can enhance longevity. Ensure that fluid levels are adequate and replace filters as needed to maintain clean and efficient operation.

| Issue | Symptoms | Solution |

|---|---|---|

| Fluid Leak | Puddles under the vehicle | Inspect and replace damaged seals |

| Overheating | High temperature readings | Check fluid levels and radiators |

| Irregular Shifting | Unresponsive or delayed shifts | Examine the control system and adjust as necessary |

Best Practices for Lubrication

Effective maintenance of machinery relies heavily on proper lubrication. Ensuring that all moving components are adequately lubricated can prevent wear and tear, enhance performance, and prolong the lifespan of equipment. Adopting a systematic approach to lubrication is essential for optimal operation and reliability.

Choosing the Right Lubricant

Selecting the appropriate lubricant is crucial. Different machines and components require specific types of oils or greases tailored to their operating conditions. Refer to manufacturer guidelines to identify the correct lubricant type, considering factors such as temperature range, load capacity, and environmental conditions. Utilizing the right product minimizes friction and protects against corrosion.

Establishing a Regular Schedule

A consistent lubrication schedule helps maintain machinery in peak condition. Determine intervals based on usage patterns and environmental factors, ensuring that lubricants are replenished before they become depleted. Regular checks and timely application can prevent breakdowns and costly repairs, allowing for smoother operation and increased productivity.

Replacing Wear Parts Effectively

Maintaining machinery in peak condition requires timely replacement of components that experience significant wear. Ensuring that these parts are swapped out efficiently not only enhances the performance of the equipment but also prolongs its lifespan. Understanding the process and utilizing the right techniques can lead to successful outcomes and reduced downtime.

Identifying Worn Components

Before any replacement can take place, it’s crucial to identify which components are underperforming. Regular inspections should be part of a maintenance routine. Look for signs such as unusual noises, decreased efficiency, or visible damage. Documentation of these observations can aid in tracking wear patterns over time.

Installation Best Practices

Once the necessary parts are determined, proper installation is key. Ensure that you have the correct tools and follow the manufacturer’s specifications. Pay attention to alignment and torque settings to prevent future issues. Utilizing high-quality replacement parts can also make a significant difference in performance and durability.

Safety Precautions During Repairs

When engaging in maintenance tasks, prioritizing safety is essential to prevent accidents and ensure a secure working environment. Proper precautions not only protect the individual performing the work but also safeguard surrounding personnel and equipment. Adhering to established guidelines is crucial for a successful and safe experience.

Personal Protective Equipment (PPE)

Wearing appropriate personal protective gear is vital. This includes safety goggles, gloves, hard hats, and steel-toed boots, which collectively reduce the risk of injury. Ensure that all equipment is in good condition and fits properly before commencing any task. Regularly inspect your PPE to maintain its effectiveness.

Work Environment Safety

Maintaining a clean and organized workspace is fundamental. Remove any unnecessary tools or materials that could pose a tripping hazard. Ensure proper ventilation in enclosed spaces and be aware of the location of emergency exits and fire extinguishers. Additionally, keep all liquids and hazardous materials stored safely to prevent spills or accidents.

Utilizing the Repair Manual

Accessing a comprehensive guide for maintenance and troubleshooting is essential for any machinery operator. Such resources not only enhance understanding of equipment but also streamline the process of addressing issues that may arise during operation. By leveraging these instructional documents, users can ensure optimal performance and longevity of their machines.

Effective use of the guide involves familiarization with its structure and contents. Here are key sections often found in these resources:

| Section | Description |

|---|---|

| Introduction | An overview of the equipment and its specifications. |

| Safety Guidelines | Important precautions to ensure safe operation and maintenance. |

| Maintenance Schedules | Recommended intervals for routine inspections and servicing. |

| Troubleshooting | Step-by-step instructions for identifying and resolving common issues. |

| Parts Catalog | A detailed list of components with diagrams for easy identification. |

By thoroughly understanding these sections, operators can effectively manage their machinery, ensuring that they are prepared to tackle challenges as they arise. The knowledge gained from these documents empowers users to perform both preventive and corrective actions confidently.

When to Seek Professional Help

Understanding when to call in an expert can save time, money, and frustration. While some tasks can be handled independently, others may require specialized knowledge or equipment. Recognizing the signs that indicate the need for professional assistance is crucial for maintaining optimal performance and safety.

Consider seeking expert help in the following situations:

- Complex Issues: If the problem involves intricate systems or components that are beyond basic troubleshooting.

- Safety Concerns: If a malfunction poses a risk to safety, it’s vital to have a qualified technician address the issue.

- Lack of Tools: When the necessary tools for a specific task are not available, professional assistance may be required.

- Time Constraints: If time is limited and the issue needs immediate attention, hiring an expert can expedite the process.

- Persistent Problems: If an issue recurs despite your attempts to resolve it, an expert’s insight might be necessary.

Evaluating these factors can help determine the best course of action, ensuring that machinery remains efficient and reliable.