Understanding the intricacies of a robust off-road vehicle can greatly enhance its longevity and performance. This guide offers insights into the essential processes required to ensure optimal functionality and efficiency. Proper maintenance not only extends the lifespan of the vehicle but also enhances the driving experience.

Key components of the vehicle play a crucial role in its overall performance. Regular assessments and timely interventions can prevent minor issues from escalating into significant challenges. Familiarity with these elements empowers owners to address concerns proactively and maintain peak condition.

Knowledge of maintenance techniques is vital for anyone seeking to maximize their vehicle’s capabilities. This guide aims to equip readers with the necessary skills and understanding to tackle common challenges, ensuring that their off-road experience remains enjoyable and trouble-free.

When working on automotive systems, having the right equipment is crucial for ensuring efficiency and precision. The selection of tools not only facilitates the maintenance process but also enhances safety and effectiveness during the task.

| Tool | Description |

|---|---|

| Socket Set | A comprehensive set of sockets allows for the removal and installation of various fasteners, providing versatility for different tasks. |

| Torque Wrench | This instrument ensures that fasteners are tightened to the manufacturer’s specifications, preventing damage and ensuring proper assembly. |

| Diagnostic Scanner | A diagnostic tool aids in identifying issues by reading trouble codes, making troubleshooting more straightforward. |

| Multimeter | This device is essential for measuring voltage, current, and resistance, which helps in electrical system diagnostics. |

| Fluid Pump | Ideal for transferring liquids, this tool makes the process of fluid changes much cleaner and more efficient. |

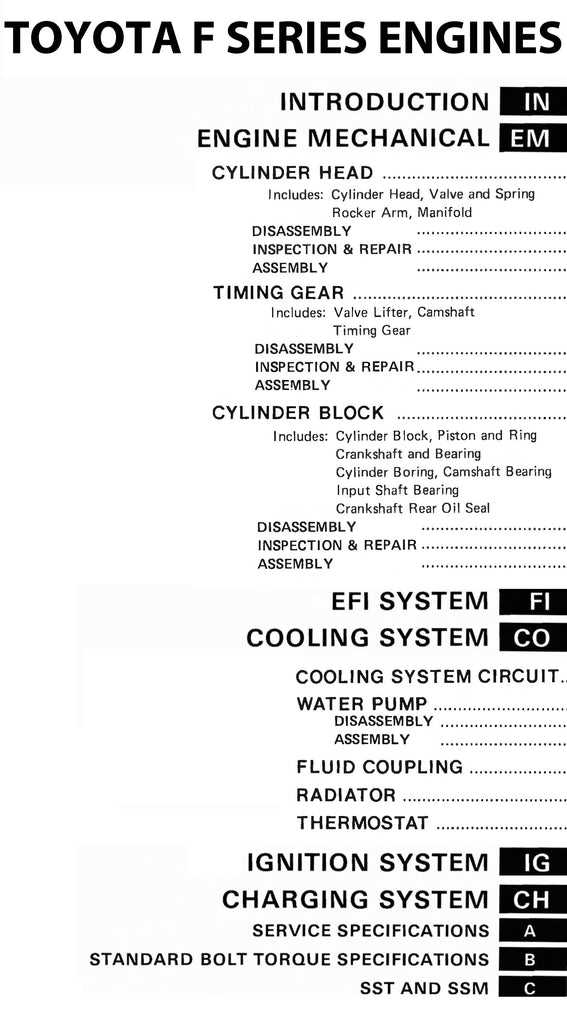

Step-by-Step Disassembly Process

The disassembly procedure of a mechanical unit involves careful planning and systematic actions to ensure each component is properly handled and recorded. Following a structured approach not only simplifies the task but also minimizes the risk of damage to any part.

Preparation and Safety Measures

Before initiating the disassembly, it is essential to gather the necessary tools and protective equipment. Ensure that the workspace is clean and well-organized. Familiarize yourself with the assembly layout to understand how various parts are interconnected. This knowledge will aid in reassembly later on.

Sequential Component Removal

Begin by removing any external attachments or coverings. Next, follow a logical sequence to detach components, starting from the outermost parts and working inward. Keep track of all fasteners and connectors, as proper reorganization will facilitate efficient reassembly. Document each step with notes or photographs to reference during the reconstruction phase.

Inspecting Engine Components

Regular evaluation of vital mechanical parts is essential for maintaining optimal performance and longevity. This process involves examining various components to ensure they function correctly and efficiently. Through systematic inspection, potential issues can be identified early, reducing the risk of significant malfunctions.

Key Areas of Focus

During the evaluation, pay particular attention to the following areas: seals and gaskets, which prevent fluid leaks; bearings, which support rotating elements; and valves, which control the flow of air and fuel. Checking for wear and tear in these components can help prevent more severe problems in the future.

Tools and Techniques

Utilizing appropriate tools such as torque wrenches and compression gauges can enhance the accuracy of your inspections. Following a methodical approach ensures that all components are thoroughly assessed, allowing for informed decisions regarding any necessary adjustments or replacements.

Reassembling the Engine Properly

When putting components back together, it is essential to follow a systematic approach to ensure functionality and longevity. A meticulous reassembly process can prevent potential issues and enhance performance.

Preparation is Key: Before starting, gather all necessary tools and components. Clean each part thoroughly to remove any debris or contaminants that could interfere with the assembly process.

Sequential Assembly: Follow the manufacturer’s guidelines for the order of assembly. Begin with the base components, gradually adding parts in a logical sequence. This method minimizes the risk of missing steps or misalignment.

Torque Specifications: Adhere to the specified torque settings for each fastener. Using a torque wrench ensures that connections are secure without being overly tight, which could lead to damage.

Final Checks: Once assembly is complete, conduct a thorough inspection. Verify that all components are correctly positioned and secured. This step is crucial for preventing issues during operation.

Lubrication and Oil Change Tips

Proper maintenance of lubricants is essential for ensuring optimal performance and longevity of your vehicle’s components. Regularly updating these fluids helps prevent wear and tear, ultimately enhancing efficiency and reliability.

When performing oil changes, always choose high-quality products that meet the specifications recommended for your vehicle. It’s advisable to change the oil and filter at regular intervals, typically every 3,000 to 5,000 miles, depending on driving conditions and oil type.

Before starting the process, ensure the engine is warm but not too hot, as this facilitates the drainage of used oil. Always use a funnel to avoid spills and consider using a drain pan to catch the old lubricant. After draining, properly dispose of the used oil and filter at designated recycling centers.

After replacing the oil, remember to check the level with the dipstick and top off if necessary. Regular checks of other lubricants, such as transmission fluid and differential oils, will also contribute to the overall health of the vehicle.

Electrical System Troubleshooting

This section aims to guide users through the process of diagnosing and resolving issues within the electrical system of their vehicle. A well-functioning electrical system is crucial for the optimal performance of various components, and identifying problems early can prevent further complications.

Common symptoms that may indicate electrical system issues include:

| Symptom | Possible Cause |

|---|---|

| Dim or flickering lights | Weak battery or poor connections |

| Failure to start | Defective starter motor or battery |

| Inconsistent gauge readings | Faulty sensors or wiring issues |

| Unresponsive accessories | Blown fuses or damaged wiring |

By systematically assessing each component and its connections, one can effectively identify and rectify electrical issues, ensuring reliable vehicle operation.

Cooling System Maintenance Guidelines

The proper upkeep of the cooling mechanism is crucial for ensuring optimal performance and longevity of any vehicle. Regular maintenance helps prevent overheating and related issues, thereby enhancing overall efficiency. This section outlines essential practices to keep the cooling system in excellent condition.

Routine Inspection and Cleaning

Regular checks of the cooling components can help identify potential problems before they escalate. It is important to inspect hoses, radiators, and other parts for wear and leaks. Cleaning the radiator and ensuring unobstructed airflow are vital steps in maintaining an effective cooling system.

Fluid Level and Quality Management

Monitoring the coolant level and its condition is essential for proper operation. Low coolant levels can lead to overheating, while contaminated fluid can cause corrosion and system failures. It is recommended to flush the cooling system and replace the coolant according to the manufacturer’s guidelines.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Inspect hoses and connections | Every 6 months | Look for cracks and wear |

| Flush cooling system | Every 2 years | Follow with new coolant |

| Check coolant level | Monthly | Add fluid if necessary |

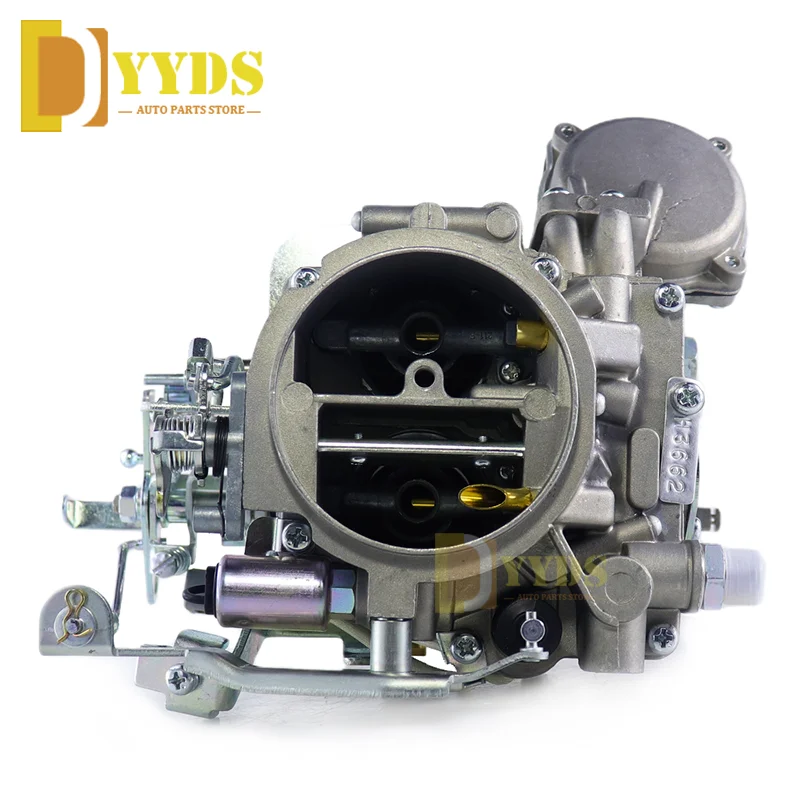

Fuel System Check and Repairs

This section focuses on the assessment and maintenance of the fuel delivery components in a vehicle. Proper functioning of these parts is crucial for optimal performance and efficiency. Regular checks can help identify issues before they escalate, ensuring a smooth operation.

Inspection Procedures

Conducting a thorough examination involves several steps:

- Check for leaks in fuel lines and connectors.

- Inspect the fuel filter for clogs and contamination.

- Examine the fuel pump operation and pressure.

- Assess the condition of the fuel injectors.

Common Issues and Solutions

Identifying typical problems can lead to effective resolutions:

- Leak Detection: Use a suitable liquid to locate leaks in the lines.

- Clogged Filter: Replace the fuel filter regularly to avoid blockage.

- Pump Failure: Test the pump voltage and replace if necessary.

- Injector Malfunction: Clean or replace injectors if they are not functioning properly.

Exhaust System Inspection Procedures

The evaluation of the exhaust assembly is crucial for ensuring optimal performance and emissions control in vehicles. Regular inspection can identify potential issues that may lead to decreased efficiency or harmful emissions. This section outlines systematic approaches to assess the exhaust components effectively.

Visual Inspection

Begin with a thorough visual examination of the entire exhaust structure. Look for signs of corrosion, cracks, or any physical damage to the pipes and joints. Ensure that all connections are secure and check for any exhaust leaks, which can often be detected by the presence of soot or discoloration around the seams.

Functional Testing

After the visual assessment, conduct functional tests to verify that the exhaust system operates correctly. Start the vehicle and listen for unusual noises that may indicate blockages or malfunctioning parts. Additionally, inspect the system while the engine is running to identify any leaks or irregularities in exhaust flow.

Performance Tuning and Adjustments

Tuning and adjustments play a crucial role in optimizing the capabilities of a vehicle’s power unit. By fine-tuning various parameters, it is possible to enhance overall performance, efficiency, and responsiveness. This section explores essential practices to achieve improved performance through precise adjustments and modifications.

Key Areas for Enhancement

- Air Intake: Modifying the air intake system can significantly improve airflow, resulting in better combustion and increased power output.

- Fuel Delivery: Adjusting fuel injectors and ensuring optimal fuel pressure can enhance the air-fuel mixture, leading to improved efficiency.

- Exhaust System: Upgrading the exhaust components can reduce back pressure, allowing for smoother exhaust flow and improved engine performance.

Adjustment Techniques

- Regularly check and clean air filters to maintain optimal airflow.

- Monitor and adjust the fuel pressure to ensure an ideal mixture.

- Use tuning software to analyze performance data and make informed adjustments.

Implementing these tuning practices can result in a noticeable difference in the vehicle’s behavior on the road. Consistent monitoring and adjustments will help maintain peak performance and reliability.

Safety Practices During Repairs

When undertaking maintenance tasks on vehicles, adhering to safety protocols is essential to ensure a secure working environment. Implementing proper practices not only protects the individual but also minimizes the risk of damage to the vehicle and its components.

Essential Safety Gear

- Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and steel-toed boots.

- Consider using ear protection if working with loud machinery or tools.

- Ensure that clothing is suitable and not loose to avoid entanglement in moving parts.

Work Environment Preparation

- Keep the workspace clean and free of clutter to prevent accidents.

- Ensure proper lighting to clearly see all components and tools.

- Have a fire extinguisher nearby in case of emergencies.