Understanding the intricacies of small engine systems is essential for anyone looking to keep their outdoor equipment in peak condition. Whether you’re a seasoned professional or a novice enthusiast, having access to comprehensive information can significantly enhance your repair skills. This resource aims to provide detailed insights into troubleshooting and upkeep techniques tailored for specific engine models.

With a focus on common issues and solutions, this guide delves into the critical aspects of engine care, from recognizing symptoms of malfunction to performing essential adjustments. Empowering users with practical knowledge ensures that they can confidently tackle repairs and maintain optimal performance of their machinery.

Through step-by-step instructions and helpful tips, you’ll find everything needed to address typical challenges. Familiarity with engine components and their functions not only aids in successful repairs but also prolongs the life of your equipment, making this information invaluable for any owner.

Understanding Briggs and Stratton Engines

When exploring small engine technology, it’s essential to appreciate the intricate design and engineering that contribute to efficient performance. These power sources are commonly found in outdoor equipment, offering reliability and durability for various applications. Their mechanics combine simplicity with advanced features, making them accessible to both novices and experienced users.

Key components play a crucial role in the functionality of these engines. The combustion chamber is where fuel and air mix, leading to the ignition process that powers the machine. The crankshaft translates the explosive energy into rotational motion, driving the equipment forward. Understanding these elements can significantly enhance maintenance efforts and overall lifespan.

Moreover, regular upkeep is vital to ensure optimal operation. Routine checks on oil levels, air filters, and spark plugs can prevent common issues and enhance efficiency. By familiarizing oneself with the engine’s workings, users can troubleshoot problems and implement solutions, reducing downtime and extending the life of their equipment.

In summary, a foundational knowledge of small engine mechanics not only aids in basic maintenance but also empowers users to make informed decisions regarding repairs and enhancements. Embracing this understanding paves the way for improved performance and satisfaction in operating outdoor machinery.

Common Issues with Model 31H777

This section highlights frequent problems encountered with a specific engine type. Understanding these common challenges can aid users in maintaining optimal performance and prolonging the lifespan of their equipment.

- Starting Difficulties:

- Weak or dead battery.

- Fuel delivery issues.

- Clogged air filter.

- Overheating:

- Low oil levels.

- Blocked cooling fins.

- Malfunctioning thermostat.

- Unusual Noises:

- Loose or damaged components.

- Worn bearings.

- Defective belts.

- Vibration Issues:

- Imbalanced parts.

- Improperly mounted engine.

- Worn-out mounts.

- Fuel Consumption:

- Dirty carburetor.

- Incorrect fuel mixture.

- Leakages in fuel lines.

Addressing these concerns promptly can prevent more severe complications and ensure the unit operates smoothly.

Essential Tools for Repairing 31H777

When tackling maintenance or fixing tasks on small engines, having the right instruments at your disposal is crucial. Each tool serves a specific purpose, ensuring that the process is efficient and effective. Below is a compilation of essential implements that will aid in addressing common issues encountered with the engine in question.

| Tool | Description |

|---|---|

| Socket Set | A variety of sizes to fit different bolts and nuts, facilitating easy removal and installation. |

| Screwdriver Set | Includes both flathead and Phillips screwdrivers, essential for handling screws found in various components. |

| Wrench Set | Adjustable and standard wrenches to grip and turn nuts securely. |

| Torque Wrench | Ensures that bolts are tightened to the manufacturer’s specifications, preventing damage. |

| Pliers | Used for gripping and twisting wires or small parts, enhancing control during adjustments. |

| Fuel System Cleaner | Helps in maintaining fuel lines and carburetors, promoting optimal performance. |

| Safety Gear | Gloves and goggles to protect hands and eyes during maintenance work. |

Step-by-Step Maintenance Guide

Proper upkeep of your engine is essential for optimal performance and longevity. Following a structured approach can prevent issues and enhance efficiency. This guide outlines crucial steps to ensure your machine runs smoothly.

-

Gather Necessary Tools

- Wrench set

- Screwdriver set

- Oil filter wrench

- Fuel stabilizer

- Air compressor (optional)

-

Check and Change the Oil

- Warm up the engine for a few minutes to thin the oil.

- Locate the drain plug and remove it to empty the old oil.

- Replace the drain plug and refill with fresh oil.

-

Inspect the Air Filter

- Remove the air filter cover.

- Check for dirt and debris; clean or replace as needed.

- Ensure the filter fits snugly in place when reassembling.

-

Examine Spark Plug

- Disconnect the spark plug wire.

- Remove the spark plug and inspect for wear or carbon buildup.

- Clean or replace the spark plug, ensuring proper gap settings.

-

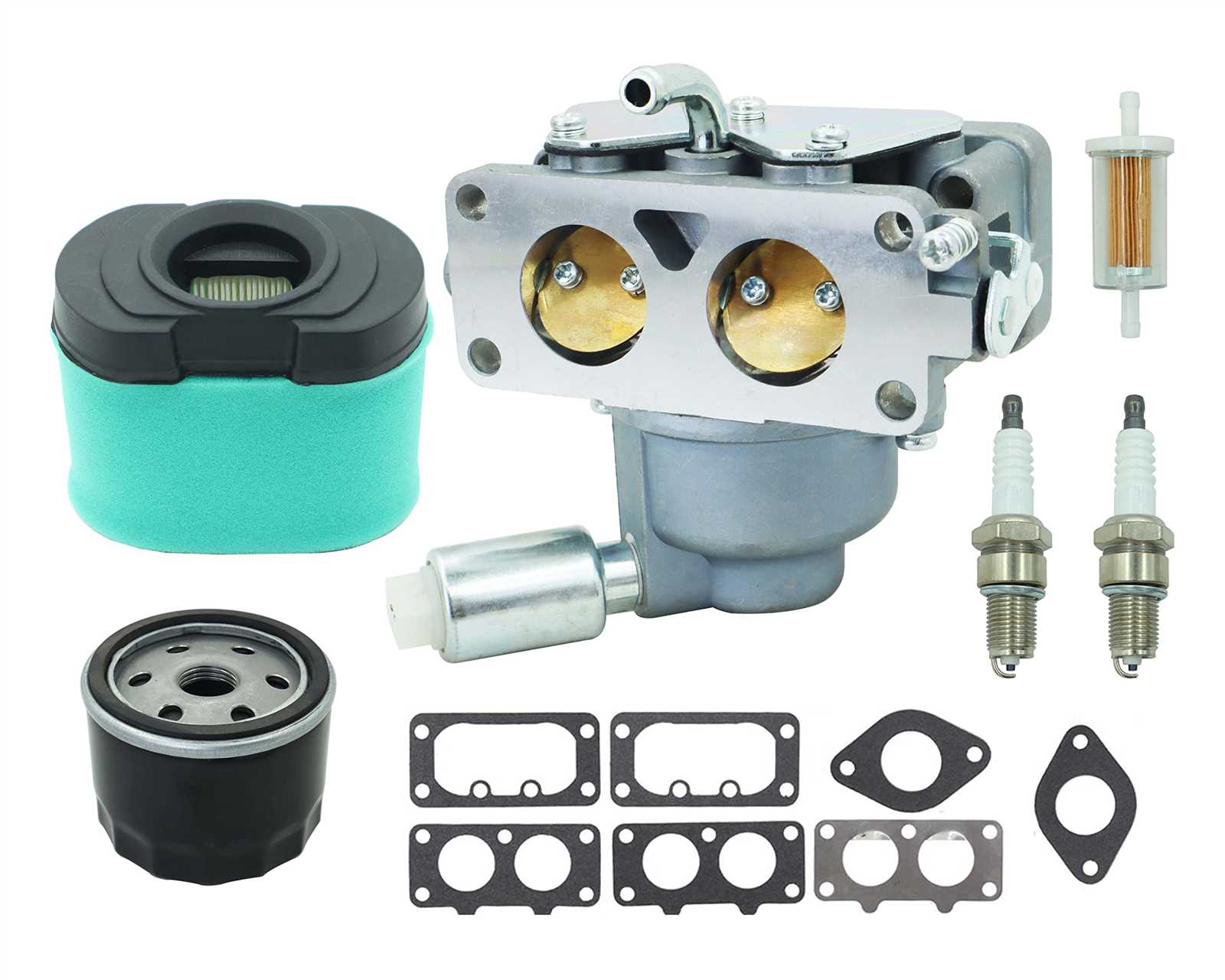

Fuel System Maintenance

- Check fuel lines for cracks or leaks.

- Replace the fuel filter if applicable.

- Add a fuel stabilizer to prevent degradation, especially for off-season storage.

-

Clean External Parts

- Use a soft brush or cloth to remove dirt and debris.

- Check for any loose bolts or screws and tighten as necessary.

- Inspect cooling fins for obstructions to ensure proper airflow.

Regular maintenance will not only improve the performance of your equipment but also extend its lifespan. Following these steps systematically will help in avoiding costly repairs down the line.

Diagnosing Engine Performance Problems

Identifying issues related to engine functionality is essential for maintaining optimal performance. Various symptoms can indicate underlying problems, and recognizing these signs early can prevent further damage. This section provides a structured approach to troubleshooting common performance-related concerns.

Start with Observation: Pay attention to how the engine behaves during operation. Notice any irregular sounds, vibrations, or changes in speed. This initial assessment can provide valuable clues about potential issues.

Fuel System Inspection: A common source of performance troubles lies within the fuel delivery system. Check for adequate fuel flow, clogged filters, or contaminated fuel. Ensure that the fuel mixture is appropriate for the engine type.

Air Intake Assessment: Insufficient air supply can lead to poor performance. Inspect the air filter for dirt or obstructions. A clean filter allows for proper airflow, which is crucial for efficient combustion.

Ignition System Examination: The ignition system plays a vital role in engine operation. Inspect spark plugs for wear and carbon buildup. Faulty plugs can lead to misfires, causing significant performance drops.

Compression Testing: Conduct a compression test to evaluate the engine’s internal health. Low compression can indicate issues with valves, piston rings, or cylinder wear, affecting overall efficiency.

By systematically addressing these areas, one can effectively diagnose and rectify performance-related issues, ensuring the engine operates smoothly and reliably.

Replacing Spark Plugs Effectively

Changing the ignition components is essential for maintaining optimal engine performance. This process not only enhances efficiency but also extends the lifespan of the machine. Properly executed replacement ensures reliable starts and smooth operation, making it a vital task for any maintenance routine.

Tools Required: Before beginning, gather the necessary tools such as a spark plug socket, ratchet, and a torque wrench. Having the right equipment at hand simplifies the process and ensures accuracy.

Steps to Follow:

- Ensure Safety: Disconnect the spark plug wire to prevent accidental ignition.

- Remove Old Spark Plug: Use the spark plug socket to unscrew the old component carefully.

- Inspect and Prepare: Check the condition of the removed plug for signs of wear or damage. Clean the area to avoid contamination.

- Install New Spark Plug: Apply a small amount of anti-seize compound to the threads, then insert the new plug and tighten it to the manufacturer’s specifications using the torque wrench.

- Reconnect: Finally, reattach the spark plug wire securely.

By following these steps diligently, you can ensure effective ignition component replacement, promoting smoother operation and improved reliability for your equipment.

Fuel System Troubleshooting Techniques

When dealing with issues related to the fuel system of small engines, a systematic approach can significantly aid in diagnosing and resolving problems. Understanding the various components and their interactions is essential for effective troubleshooting. This guide offers valuable insights into common issues and methods to identify them efficiently.

1. Check for Fuel Flow: Begin by inspecting the fuel lines for any blockages or leaks. Ensure that fuel is reaching the carburetor without obstruction. If the flow is insufficient, consider replacing damaged hoses or clearing any debris that may be causing restrictions.

2. Inspect the Fuel Filter: A clogged fuel filter can impede proper fuel delivery. Remove and examine the filter for signs of contamination or buildup. If necessary, replace it to restore optimal fuel flow.

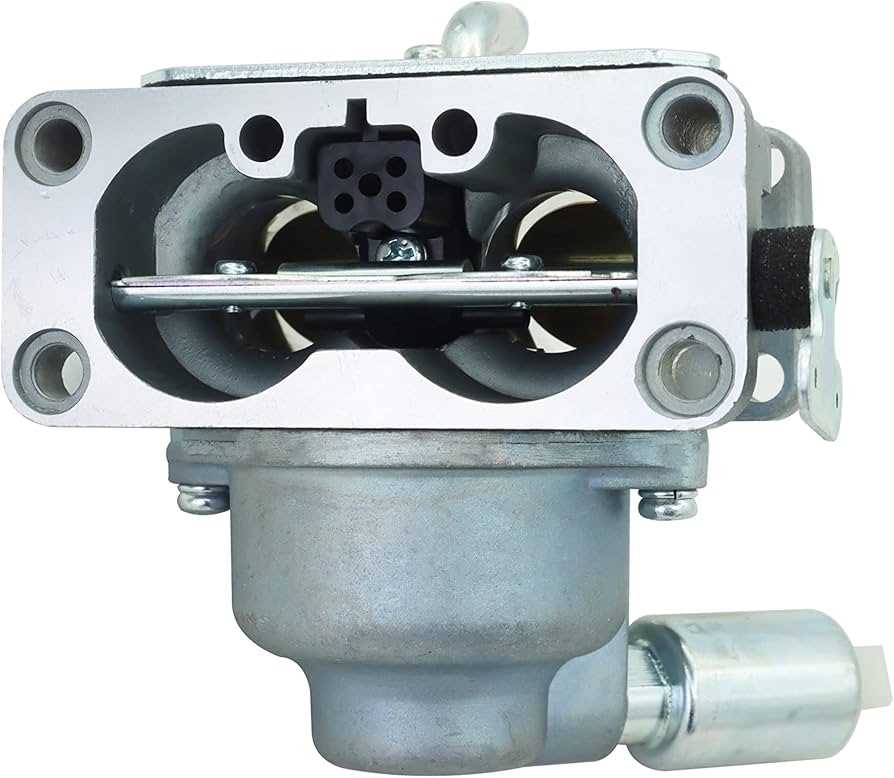

3. Examine the Carburetor: The carburetor is a critical component in the fuel system. Look for signs of wear, dirt, or varnish buildup. Cleaning or rebuilding the carburetor may be necessary to ensure it functions properly.

4. Test the Fuel Quality: Old or contaminated fuel can lead to engine performance issues. Drain the fuel tank and replace it with fresh fuel to eliminate this potential problem.

5. Assess Fuel Pump Functionality: If applicable, check the fuel pump to ensure it is operating correctly. Listen for any unusual noises and verify that it is delivering fuel as intended.

By following these techniques, you can effectively identify and resolve issues within the fuel system, ensuring optimal performance and reliability of your engine.

Oil Change Procedures for Longevity

Regular maintenance of your small engine is essential for ensuring its optimal performance and extending its lifespan. One of the most crucial tasks in this maintenance routine is the oil change. Properly addressing this aspect not only helps maintain engine efficiency but also prevents premature wear and tear, allowing your equipment to function smoothly for years to come.

Steps for Effective Oil Change

Begin by gathering the necessary tools and materials, including a new oil filter, the appropriate type of oil, a drain pan, and a wrench. First, ensure the engine is cool and positioned on a level surface. Remove the drain plug and allow the old oil to flow into the pan, taking care to dispose of it according to local regulations. Once drained, replace the drain plug securely.

Next, replace the oil filter if applicable, ensuring the new filter is installed correctly. After this, pour in the new oil through the filler cap, checking the owner’s guidelines for the correct capacity. Finally, run the engine for a few minutes and check for leaks, topping off the oil as necessary. Regular oil changes, typically every 50 hours of operation or annually, can significantly enhance the reliability and durability of your engine.

Benefits of Timely Oil Changes

Frequent oil changes help remove contaminants that accumulate over time, which can lead to engine damage. Fresh oil also provides better lubrication, reducing friction between moving parts. By adhering to a consistent schedule, you ensure that your engine runs efficiently, operates quietly, and maintains its performance, ultimately saving you time and money on repairs.

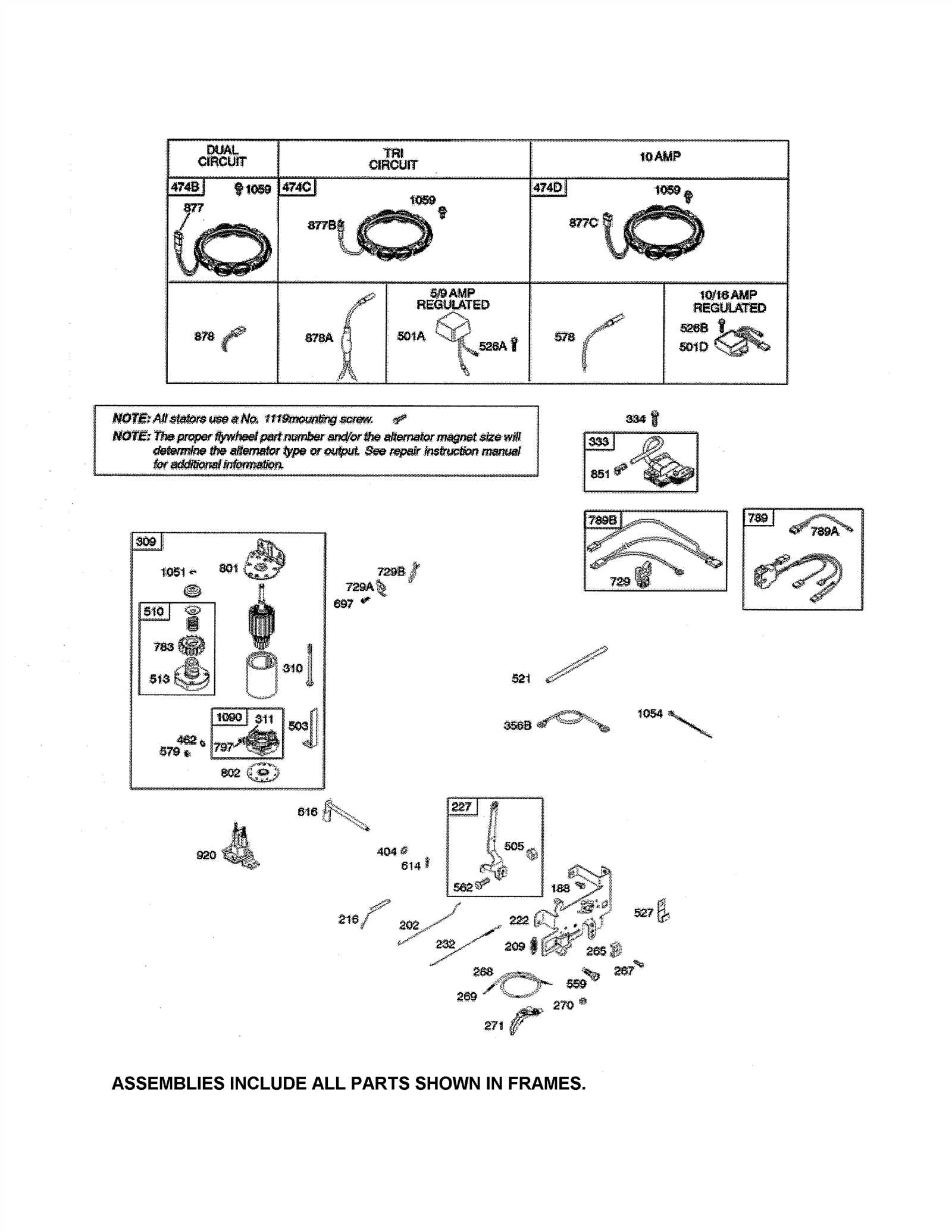

Understanding Electrical Components

Electrical systems are vital for the efficient functioning of various machinery, playing a crucial role in both performance and safety. Familiarity with these components allows users to identify potential issues and maintain optimal operation. This section delves into the key elements that comprise electrical systems, enhancing your knowledge and troubleshooting skills.

Main Components

- Battery: Provides the necessary power to start the engine and run electrical accessories.

- Starter Motor: Engages the engine to initiate combustion and operation.

- Ignition System: Generates the spark required for fuel ignition, ensuring efficient engine function.

- Alternator: Charges the battery while the engine is running and powers electrical systems.

- Wiring Harness: Connects various components, facilitating the flow of electricity throughout the system.

Common Issues

- Dead Battery: Often caused by prolonged inactivity or faulty charging systems.

- Starter Failure: Can result from worn components or poor electrical connections.

- Ignition Problems: May stem from faulty spark plugs or issues within the ignition system.

- Alternator Malfunction: Can lead to battery drainage and electrical failures.

Understanding these components and their potential problems can significantly improve maintenance and repair processes, ensuring longevity and reliability of the equipment.

Carburetor Cleaning and Adjustment

Maintaining the fuel delivery system is essential for optimal engine performance. Regular cleaning and proper tuning of the carburetor can enhance efficiency, reduce emissions, and prevent potential issues. This section outlines effective methods for cleaning and adjusting the carburetor to ensure smooth operation.

Cleaning Process

Begin by disconnecting the fuel supply and removing the carburetor from the engine. Disassemble the unit carefully, noting the arrangement of parts. Use a carburetor cleaner to eliminate deposits and dirt. Pay close attention to jets and passages, ensuring they are free of obstructions. A soft brush can be useful for scrubbing surfaces without causing damage. Rinse components thoroughly and allow them to dry completely before reassembling.

Adjustment Techniques

After cleaning, reassemble the carburetor and install it back onto the engine. Start by adjusting the idle speed screw to achieve a stable idle. Then, fine-tune the air-fuel mixture using the mixture screw. Make small adjustments while monitoring engine response. It’s crucial to achieve a balance for optimal combustion, which will enhance performance and fuel economy.

Regular maintenance of the fuel system is key to longevity. Following these steps will ensure reliable performance and a smoother running engine.

Safety Precautions During Repairs

When working on machinery, ensuring personal safety should always be a top priority. Proper precautions can prevent accidents and injuries, allowing for a smoother and more efficient process. By adhering to certain guidelines, individuals can protect themselves and their surroundings while conducting maintenance tasks.

Essential Safety Guidelines

Prior to beginning any service work, it’s crucial to familiarize oneself with the following measures:

| Guideline | Description |

|---|---|

| Wear Protective Gear | Always don gloves, goggles, and appropriate clothing to shield against debris and hazardous materials. |

| Disconnect Power Sources | Ensure all electrical connections are unplugged and fuel lines are shut off to prevent unexpected starts. |

| Work in a Well-Ventilated Area | Perform tasks in a space with adequate airflow to reduce exposure to harmful fumes. |

| Keep a First Aid Kit Handy | Maintain easy access to first aid supplies in case of minor injuries. |

Emergency Preparedness

In addition to the basic safety measures, it’s essential to be prepared for emergencies. Familiarize yourself with the location of fire extinguishers and emergency exits. Regularly review first aid procedures and ensure that all involved individuals know how to respond to various incidents. Being proactive can significantly minimize risks during maintenance activities.

Finding Replacement Parts Online

Locating suitable components for your engine online can streamline maintenance and repair tasks significantly. With a plethora of resources available, it’s essential to navigate through options effectively to ensure you acquire the correct items for your specific needs. Online marketplaces, manufacturer websites, and specialized retailers offer a wide range of choices that can meet various requirements.

When searching for components, begin by gathering as much information as possible about your engine model. This includes serial numbers, part descriptions, and compatibility details. Utilizing this information in your searches will help narrow down results and increase the likelihood of finding the right parts. Many online platforms feature detailed filters, allowing you to sort by brand, size, or type, enhancing the overall shopping experience.

Additionally, consider reading customer reviews and product ratings to gauge the reliability and quality of the components you are interested in. Reputable vendors often provide insights from previous buyers, helping you make informed decisions. Don’t hesitate to contact customer service for clarification or assistance, as knowledgeable staff can offer guidance tailored to your specific situation.

Lastly, be mindful of shipping options and return policies. Opting for suppliers that provide clear information on delivery times and return processes can save you time and hassle in the long run. By utilizing these strategies, you can confidently find the parts you need for effective engine upkeep.

When to Seek Professional Help

Understanding when to consult an expert can be crucial for maintaining your equipment’s performance and longevity. Certain situations may arise that require specialized knowledge, tools, or experience beyond basic troubleshooting. Recognizing these moments can save time, prevent further damage, and ensure safety.

One sign that professional assistance is needed is when you encounter persistent issues that do not resolve with standard maintenance techniques. If your device exhibits unusual noises, leaks, or erratic behavior, it might indicate deeper mechanical problems. Attempting to fix these without expertise could lead to more extensive damage.

Another important factor is safety. If you are unsure about handling electrical components or dealing with high-pressure systems, seeking professional help is advisable. Safety should always be a priority, and experts are equipped to manage risks effectively.

Finally, if the repair requires specialized tools or diagnostic equipment, it is best to rely on professionals. Investing in such tools for a one-time fix may not be cost-effective. Professionals have access to the necessary resources and knowledge to perform repairs efficiently.