The upkeep of agricultural equipment is crucial for ensuring optimal performance and longevity. Proper guidance and resources can make a significant difference in the efficiency of these powerful machines. Understanding the intricacies of their operation and maintenance is essential for any owner or operator aiming to maximize productivity.

In this section, we delve into comprehensive resources designed to assist users in navigating the complexities of machinery upkeep. From troubleshooting common issues to routine servicing protocols, these materials provide invaluable insights that can help maintain peak functionality.

Additionally, users will discover best practices for parts replacement and preventative measures that can mitigate the risk of breakdowns. By familiarizing oneself with these resources, operators can enhance their knowledge and skill set, ultimately leading to improved outcomes in their agricultural endeavors.

Massey Ferguson 165 Overview

This section offers a comprehensive look at a renowned agricultural machine known for its durability and performance. Designed to meet the needs of various farming operations, it combines efficiency with user-friendly features, making it a favorite among farmers.

Engine Performance: Equipped with a robust engine, this tractor delivers reliable power for a multitude of tasks. Its design emphasizes fuel efficiency without compromising on output, ensuring optimal operation in diverse conditions.

Versatility: This machine excels in a range of applications, from tilling to hauling. Its adaptability allows operators to seamlessly switch between different farming implements, enhancing productivity and reducing downtime.

Maintenance: Regular upkeep is essential to maintain its peak performance. Understanding the key maintenance practices ensures longevity and efficiency, helping farmers get the most out of their investment.

Common Issues with MF 165

When it comes to agricultural machinery, various problems can arise over time, affecting performance and efficiency. Understanding these frequent challenges is crucial for maintaining optimal functionality and ensuring longevity. This section highlights some prevalent concerns that operators may encounter.

One typical issue involves the engine’s performance, where difficulties in starting or irregular idling can occur. These symptoms may stem from fuel delivery problems or ignition system malfunctions. Regular inspections of these components are essential for smooth operation.

Another common challenge is related to hydraulic systems, which may show signs of leakage or inadequate pressure. Such issues can hinder the effectiveness of implements and attachments. It’s vital to routinely check seals and hoses to prevent further complications.

Transmission troubles can also arise, particularly with shifting gears or strange noises. These problems often indicate wear or damage in the transmission system, necessitating timely attention to avoid more extensive repairs.

Electrical faults, including battery drain or malfunctioning lights, can disrupt overall functionality. Ensuring all connections are secure and components are in good condition can mitigate these issues.

Lastly, tire wear and alignment problems can significantly impact traction and stability. Regularly inspecting tires for wear patterns and maintaining proper inflation can enhance performance on various terrains.

Essential Tools for Repairs

When it comes to maintaining and fixing agricultural machinery, having the right set of tools is crucial for efficient and effective work. A well-equipped toolkit not only enhances productivity but also ensures safety and precision during tasks. Understanding the necessary implements can significantly streamline the repair process.

Wrenches are fundamental for tightening and loosening bolts and nuts. A variety of sizes and types, including adjustable and socket wrenches, should be included in any toolkit to accommodate different fittings.

Screwdrivers come in various types, such as flathead and Phillips, and are essential for working on electrical components and machinery covers. Ensuring you have a complete set will prevent delays and frustrations during disassembly and assembly.

Pliers serve multiple purposes, from gripping to cutting wires. Needle-nose pliers are particularly useful for reaching tight spots, while locking pliers provide extra leverage when needed.

Jack and Stands are indispensable for safely lifting heavy equipment. Always use these tools to ensure stability and security while working underneath machinery, minimizing the risk of accidents.

Diagnostic Tools like multimeters and code readers are essential for troubleshooting electrical systems. These devices help in identifying faults quickly, saving time and effort in repairs.

Investing in quality tools and keeping them organized will not only make repairs easier but also prolong the lifespan of your machinery. A systematic approach to your toolkit can lead to more successful and less stressful maintenance tasks.

Step-by-Step Maintenance Guide

This guide provides a comprehensive approach to keeping your agricultural machinery in optimal condition. Regular upkeep is essential for ensuring longevity, enhancing performance, and preventing costly breakdowns. Following systematic procedures can make maintenance efficient and straightforward, allowing operators to manage their equipment with confidence.

Daily Inspection

Begin each day with a thorough visual inspection. Check for any signs of wear or damage, paying close attention to hoses, belts, and fluid levels. Ensure that all safety features are functioning correctly. Cleaning the exterior helps prevent rust and accumulation of debris, which can hinder performance.

Periodic Servicing

Schedule regular servicing every few months, focusing on fluid changes, filter replacements, and component lubrication. Refer to the operational guidelines for specific intervals. Keeping accurate records of maintenance activities can aid in tracking performance and anticipating future needs.

Understanding the Engine Components

Grasping the intricacies of engine parts is essential for effective maintenance and troubleshooting. Each component plays a vital role in ensuring the overall performance and efficiency of the machine. Familiarity with these elements can lead to better operational outcomes and longevity.

Key engine components include:

- Crankshaft: Transforms linear motion into rotational energy, driving the machine’s mechanisms.

- Pistons: Move up and down within the cylinders, compressing the fuel-air mixture for combustion.

- Cylinders: House the pistons and facilitate the combustion process.

- Camshaft: Regulates the timing of the intake and exhaust valves, crucial for engine cycles.

- Valves: Control the flow of air and fuel into the cylinders and exhaust gases out.

- Fuel Injection System: Delivers precise amounts of fuel to the combustion chamber for optimal performance.

- Cooling System: Maintains the engine temperature, preventing overheating and ensuring efficiency.

- Lubrication System: Reduces friction between moving parts, prolonging engine life and improving performance.

Each of these components must work harmoniously to achieve maximum efficiency and reliability. Understanding their functions and interrelationships is crucial for anyone involved in the upkeep of these systems.

Electrical System Troubleshooting Tips

When faced with issues in an agricultural machine’s electrical system, a systematic approach can help identify and resolve problems efficiently. Understanding common symptoms and employing effective diagnostic techniques is essential for maintaining optimal performance.

Common Symptoms of Electrical Problems

- Inconsistent engine starting

- Flickering or non-functional lights

- Failure of electronic components

- Battery drainage issues

- Unresponsive controls

Diagnostic Steps to Follow

- Check the battery condition and connections.

- Inspect wiring for signs of wear or damage.

- Test fuses and relays for continuity.

- Verify the operation of switches and sensors.

- Use a multimeter to measure voltage at critical points.

By systematically addressing each aspect of the electrical system, you can enhance reliability and prevent future complications.

Hydraulic System Repair Techniques

Effective maintenance of hydraulic systems is essential for optimal performance and longevity. Understanding common issues and employing appropriate methods can significantly enhance functionality and reliability. This section explores essential techniques for addressing hydraulic challenges.

Common Issues in Hydraulic Systems

Identifying frequent problems can streamline the troubleshooting process. Some typical concerns include:

- Fluid leaks

- Poor performance

- Unresponsive controls

- Overheating

Essential Techniques for Troubleshooting

When encountering difficulties in hydraulic systems, follow these steps for effective resolution:

- Visual Inspection: Regularly check for signs of wear, leaks, or damage.

- Fluid Quality Assessment: Ensure that the hydraulic fluid is clean and at the proper level.

- Pressure Testing: Use pressure gauges to determine if the system is operating within acceptable limits.

- Component Replacement: Swap out faulty parts, such as seals, hoses, or valves, as necessary.

Implementing these strategies can significantly improve the efficiency and safety of hydraulic operations. Regular maintenance and attention to detail will contribute to a more reliable system overall.

Parts Replacement Guide for MF 165

This section provides essential information for maintaining and replacing components in a specific tractor model. Understanding the proper procedures and parts required for upgrades can significantly enhance the machine’s performance and longevity. Following the guidelines ensures that the equipment remains in optimal working condition.

Key Components for Replacement

When it comes to upgrading or replacing parts, it is crucial to focus on components that impact functionality and efficiency. Here are some vital parts that often require attention:

| Component | Common Issues | Replacement Frequency |

|---|---|---|

| Engine Oil Filter | Clogging, Reduced Performance | Every 100 hours |

| Air Filter | Poor Airflow, Increased Fuel Consumption | Every 200 hours |

| Fuel Filter | Contaminated Fuel, Starting Issues | Every 500 hours |

| Battery | Weak Charge, Starting Failures | Every 3-5 years |

| Tires | Worn Treads, Poor Traction | As needed |

Maintenance Tips

Regular inspection and proactive replacement of these components can prevent unexpected breakdowns. Ensure to consult with specialists for guidance on selecting compatible parts and follow manufacturer recommendations for installation.

Manuals: Where to Find Them

Locating essential documentation for agricultural machinery can significantly enhance maintenance and troubleshooting processes. These resources provide invaluable insights into operational guidelines, specifications, and servicing procedures, ensuring optimal performance and longevity of equipment.

Online Resources

The internet is a treasure trove of information, with numerous websites dedicated to agricultural machinery. Platforms such as manufacturer websites often offer downloadable documents, while forums and user groups can provide shared experiences and additional insights. Search engines can help locate specific PDFs or guides that cater to your machinery model.

Local Dealers and Workshops

Visiting authorized dealers or local repair shops can also yield useful resources. Many dealerships maintain archives of documentation and may provide copies upon request. Additionally, mechanics with extensive experience in the field often possess personal collections of manuals and can share advice based on hands-on expertise.

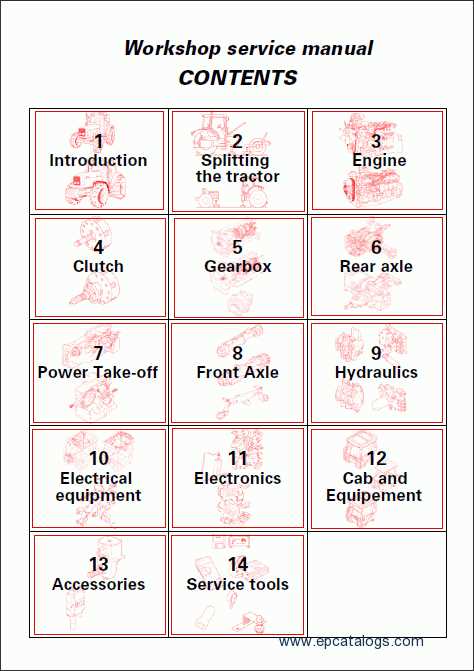

Benefits of Using Official Manuals

Utilizing authorized guides offers numerous advantages for anyone looking to maintain or troubleshoot machinery effectively. These resources are specifically designed to provide comprehensive information, ensuring that users have access to accurate and detailed instructions tailored to their equipment.

One of the primary benefits is the reliability of the content. Official documents are often created by experts who understand the intricacies of the machinery, resulting in step-by-step procedures that minimize the risk of errors during maintenance tasks. This level of precision can be crucial in preventing damage and ensuring optimal performance.

Furthermore, these guides typically include valuable troubleshooting sections, helping users quickly identify and resolve common issues. This not only saves time but also enhances the longevity of the equipment. By following established protocols, users can maintain their machinery in a cost-effective manner, avoiding unnecessary repairs or replacements.

In addition, authorized resources often contain diagrams and schematics that facilitate a better understanding of complex systems. Visual aids can significantly enhance comprehension, making it easier for individuals, regardless of their experience level, to perform tasks confidently.

Overall, the use of official resources provides peace of mind, as users can trust the information to be both accurate and up-to-date, ensuring that they are following the best practices recommended by the manufacturers.

Customer Experiences with MF 165 Repairs

This section delves into the insights shared by users regarding their experiences with maintaining and fixing a specific agricultural vehicle. Many owners have encountered various challenges and successes throughout the process, leading to a wealth of knowledge within the community. Their feedback offers valuable guidance for current and prospective operators looking to enhance the longevity and performance of their machinery.

Common Issues Reported

Users have consistently reported several frequent problems that arise with their equipment. Understanding these common issues can help others anticipate and address them effectively.

| Issue | Description | Frequency |

|---|---|---|

| Electrical Faults | Problems with wiring and connections that affect operation. | High |

| Hydraulic Leaks | Loss of fluid due to worn seals or damaged hoses. | Medium |

| Engine Performance | Reduced power or efficiency, often linked to fuel or air intake issues. | High |

| Transmission Troubles | Difficulty in shifting gears, which can impede functionality. | Medium |

Advice from the Community

Experienced users often recommend proactive maintenance and regular inspections to prevent issues before they escalate. Sharing tips on proper lubrication, checking fluid levels, and seasonal upkeep can make a significant difference. Additionally, connecting with fellow operators for advice can lead to discovering effective solutions tailored to specific challenges.