In the world of transportation, ensuring the longevity and optimal performance of commercial vehicles is paramount. This section delves into essential aspects of vehicle upkeep, providing insights into procedures that guarantee reliability on the road. Proper maintenance not only extends the lifespan of these machines but also enhances safety and efficiency.

Understanding the intricacies of heavy-duty machinery is crucial for any operator or technician. From routine inspections to complex troubleshooting, having access to detailed information empowers individuals to address issues proactively. This guide serves as a valuable resource, equipping users with the knowledge needed to tackle maintenance tasks confidently.

With a focus on systematic approaches and practical tips, this resource aims to demystify the maintenance process. Whether it’s about conducting thorough checks or performing specialized repairs, users will find a wealth of information designed to streamline their efforts. By following the outlined practices, one can ensure that vehicles remain in peak condition, ready to meet the demands of the road.

Overview of Mercedes Actros

This section provides an insightful examination of a prominent heavy-duty vehicle designed for long-distance transportation. Known for its exceptional performance and reliability, this model has become a favorite among professionals in the logistics industry.

The vehicle is equipped with cutting-edge technology that enhances both safety and efficiency. Its powerful engine options are tailored to meet various operational demands, ensuring that it can handle diverse terrains and load capacities with ease.

Innovative Features: Among its many advantages are advanced driver assistance systems, which significantly reduce the risk of accidents and improve overall driving comfort. The ergonomic design of the cabin also prioritizes the driver’s experience, offering a spacious and comfortable environment for long hours on the road.

Maintenance Considerations: Regular upkeep is essential to maintain optimal performance. This model’s engineering emphasizes durability and ease of service, making routine checks and repairs straightforward. Understanding its systems and components is crucial for any operator to ensure longevity and efficiency in operations.

Common Issues in Actros Trucks

Heavy-duty vehicles often encounter a variety of challenges that can affect their performance and longevity. Understanding these common problems is essential for effective maintenance and operation. Below are some frequent issues reported by drivers and fleet managers.

- Engine Performance:

- Unusual noises during operation.

- Reduced power output.

- Increased fuel consumption.

- Transmission Troubles:

- Shifting delays or harsh engagement.

- Fluid leaks from the transmission system.

- Electrical System Failures:

- Dashboard warning lights not functioning.

- Issues with battery charging.

- Malfunctioning sensors affecting vehicle performance.

- Brake System Concerns:

- Inconsistent braking performance.

- Worn brake pads and discs.

- Air leaks in pneumatic systems.

- Suspension Problems:

- Uneven tire wear.

- Excessive vibration during driving.

- Failing shock absorbers.

Addressing these issues promptly can help ensure the vehicle operates efficiently and safely on the road.

Essential Tools for Repairs

When it comes to maintaining and fixing large vehicles, having the right equipment is crucial for achieving optimal performance and longevity. A well-equipped toolkit not only enhances efficiency but also ensures that tasks are performed safely and effectively. Understanding the necessary instruments can greatly simplify the upkeep process.

Basic Hand Tools

Every technician should start with a solid set of hand tools. These include wrenches, screwdrivers, and pliers. Each of these items serves a unique purpose, from loosening bolts to gripping components. Investing in high-quality hand tools can make a significant difference in the ease of work.

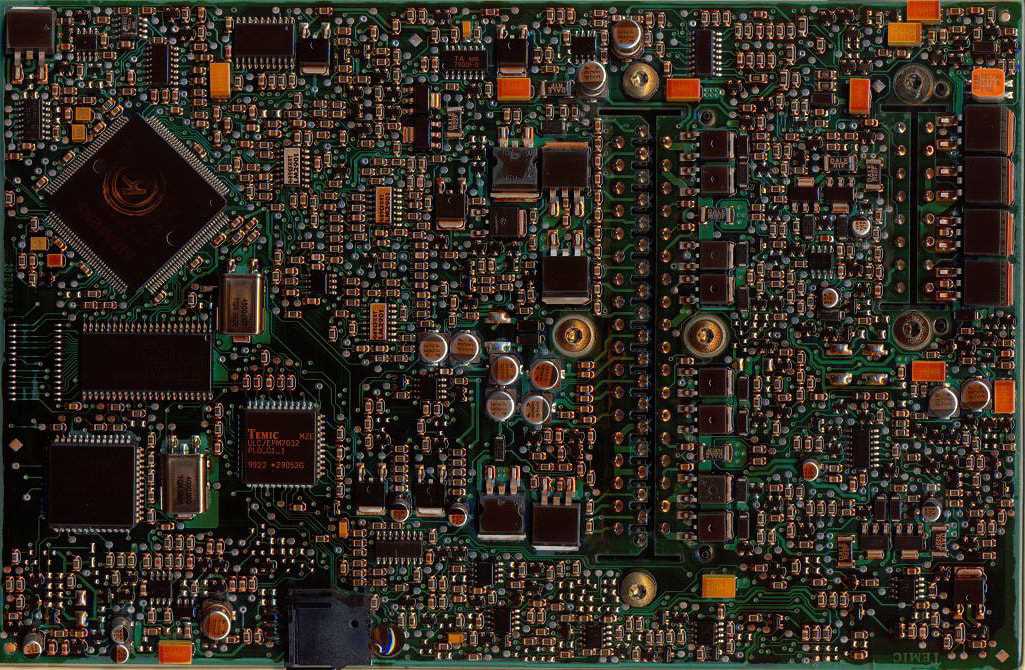

Diagnostic Equipment

In addition to basic tools, specialized diagnostic equipment is essential for identifying issues accurately. Devices such as multimeters and scan tools allow for real-time monitoring and troubleshooting of electrical and mechanical systems. These tools enable technicians to pinpoint problems quickly, reducing downtime and enhancing overall productivity.

Step-by-Step Maintenance Procedures

Regular upkeep is essential for the longevity and optimal performance of heavy-duty vehicles. By adhering to systematic procedures, operators can ensure that their machinery remains in peak condition, minimizing downtime and costly repairs.

Below is a structured guide to essential maintenance tasks:

-

Pre-Maintenance Inspection:

- Check fluid levels (oil, coolant, brake fluid).

- Inspect tires for wear and proper inflation.

- Examine lights and electrical systems for functionality.

-

Engine Care:

- Change engine oil and replace the oil filter as per the schedule.

- Inspect air filters and replace them if clogged.

- Check fuel lines for leaks and integrity.

-

Brake System Maintenance:

- Inspect brake pads and rotors for wear.

- Check brake fluid levels and top off if necessary.

- Test the braking system for responsiveness.

-

Transmission Check:

- Inspect transmission fluid for contamination.

- Ensure that the gear shift operates smoothly.

- Check for any fluid leaks beneath the vehicle.

-

Cooling System Maintenance:

- Inspect hoses for wear or leaks.

- Flush and replace coolant as recommended.

- Check the radiator for obstructions and cleanliness.

By following these steps, operators can effectively maintain their vehicles, ensuring safety and reliability on the road.

Electrical System Troubleshooting Guide

This section aims to provide a comprehensive approach to diagnosing issues within the electrical framework of heavy-duty vehicles. Understanding common faults and their potential solutions can significantly enhance operational efficiency and reduce downtime. By following a systematic troubleshooting process, operators can identify and rectify electrical malfunctions effectively.

Common Electrical Issues

Electrical problems can manifest in various forms, impacting the performance of the vehicle. Below are some typical issues encountered:

| Issue | Symptoms | Possible Causes |

|---|---|---|

| Dead Battery | No start, dim lights | Corroded terminals, faulty alternator |

| Blown Fuse | Power loss to specific components | Overloaded circuit, short circuit |

| Faulty Starter Motor | Clicking sound, no engine turnover | Worn brushes, bad solenoid |

| Malfunctioning Sensors | Warning lights, erratic readings | Wiring issues, sensor failure |

Troubleshooting Steps

To effectively address electrical issues, follow these steps:

- Check the battery and connections for corrosion or loose terminals.

- Inspect fuses and replace any that are blown.

- Test the starter motor and associated wiring.

- Use diagnostic tools to evaluate sensor performance and wiring integrity.

Engine Repair Techniques Explained

When it comes to addressing issues in complex machinery, understanding various methodologies for restoration is essential. These approaches are designed to enhance performance, prolong longevity, and ensure safety in operation. This section delves into the essential techniques utilized in the overhaul and maintenance of internal combustion units.

Diagnosis is the first critical step in any mechanical intervention. Utilizing advanced diagnostic tools allows technicians to identify malfunctions accurately. This process often involves examining electronic control systems, analyzing data from sensors, and performing physical inspections to pinpoint the root cause of the issue.

Once a problem has been identified, disassembly becomes necessary. Carefully removing components requires precision and an understanding of the assembly layout. It is crucial to document the arrangement of parts and fasteners to facilitate accurate reassembly. Techniques such as using torque specifications during this phase ensure that components are not damaged.

After disassembly, cleaning is vital. Accumulated deposits and contaminants can severely affect performance. Various methods, including ultrasonic cleaning and chemical baths, can be employed to restore parts to their original condition. This step is often complemented by inspection, where worn or damaged components are assessed for viability or need for replacement.

Once the components are cleaned and inspected, reconditioning may be required. This could involve machining surfaces to restore tolerances, replacing worn bearings, or even upgrading parts to improve efficiency. Each action taken during this phase should be executed with precision to maintain the integrity of the assembly.

Finally, reassembly and testing are crucial. Following the documented order from disassembly, components must be put back together with care. Once reassembled, thorough testing is conducted to ensure that the unit operates correctly under various conditions. This step verifies the success of all previous techniques applied and assures optimal functionality.

In summary, effective techniques for engine restoration encompass careful diagnosis, meticulous disassembly, thorough cleaning and inspection, precise reconditioning, and rigorous testing. Mastering these methodologies not only enhances performance but also safeguards the investment in mechanical systems.

Transmission Service and Maintenance Tips

Ensuring optimal performance of your vehicle’s gearbox is crucial for longevity and efficiency. Regular upkeep not only enhances functionality but also prevents costly breakdowns. Below are essential guidelines to maintain your transmission effectively.

1. Regular Fluid Checks: Periodically inspect the transmission fluid level and condition. Clean fluid should be bright red and clear. If it appears dark or has a burnt smell, it’s time for a change.

2. Fluid Change Schedule: Adhere to the manufacturer’s recommendations for fluid replacement intervals. Typically, this ranges from every 30,000 to 60,000 miles, depending on usage and vehicle type.

3. Inspect Filters: Replacing the transmission filter during fluid changes can significantly improve performance. Clogged filters restrict fluid flow, leading to overheating and damage.

4. Monitor for Leaks: Regularly check for any signs of fluid leaks under the vehicle. Early detection can prevent severe damage and costly repairs.

5. Use Correct Fluid Type: Always use the transmission fluid specified by the manufacturer. Using the wrong type can lead to poor performance and potential damage.

6. Pay Attention to Shifting: Be alert to any unusual noises or rough shifting. These symptoms may indicate underlying issues that require immediate attention.

7. Maintain Cooling System: Ensure that the cooling system is functioning properly. An overheated transmission can lead to premature wear and failure.

8. Professional Inspections: Schedule periodic professional inspections to catch any potential issues early. Technicians can provide insights that may not be visible during routine checks.

By following these maintenance tips, you can help ensure that your gearbox remains in peak condition, ultimately contributing to the overall reliability of your vehicle.

Understanding the Actros Suspension System

The suspension framework plays a crucial role in maintaining vehicle stability and comfort during transit. Its design aims to absorb shocks from uneven road surfaces, ensuring a smooth ride while supporting the weight of the vehicle and its cargo. An effective suspension system enhances handling, prolongs tire life, and contributes to overall safety.

In heavy-duty vehicles, the suspension is particularly vital due to the demands placed on it. The system typically consists of various components that work together to provide optimal performance under different load conditions. These elements include springs, shock absorbers, and air systems, each contributing to the vehicle’s ability to navigate challenging terrains.

| Component | Function |

|---|---|

| Springs | Support the vehicle’s weight and absorb road shocks. |

| Shock Absorbers | Dampen the oscillations of the springs to improve ride quality. |

| Air Suspension | Adjusts the height of the vehicle, enhancing stability and load distribution. |

Understanding these components and their interactions is essential for ensuring the longevity and efficiency of the vehicle. Regular inspections and maintenance of the suspension system can prevent costly repairs and enhance operational performance.

Braking System Inspection Guidelines

Ensuring the optimal performance of the braking system is crucial for safety and efficiency. Regular assessments help identify potential issues before they escalate, contributing to a reliable and responsive driving experience. This section outlines essential practices for inspecting braking components and systems.

Visual Inspection

Begin with a thorough visual examination of the braking system. Check for any signs of wear, such as cracked or warped discs, and ensure that brake pads have sufficient material remaining. Inspect hoses and lines for leaks or abrasions, and confirm that all connections are secure. Pay close attention to the condition of the calipers and any hydraulic components, as these are vital for effective braking performance.

Functional Testing

After completing the visual check, proceed with functional tests. Engage the brakes at various speeds to assess responsiveness and feel. Listen for unusual noises that may indicate mechanical issues. Additionally, monitor the braking system’s behavior during different driving conditions, such as wet or slippery surfaces, to ensure reliable operation. Any irregularities should prompt further investigation and potential servicing.

Regular Checks for Safety Compliance

Ensuring the safety of heavy-duty vehicles requires a systematic approach to maintenance and inspection. Regular evaluations help identify potential issues before they escalate, thereby enhancing operational reliability and compliance with safety regulations. These checks should encompass various critical components, including braking systems, lighting, and tire conditions.

It is essential to adhere to a scheduled maintenance plan that includes daily, weekly, and monthly inspections. Daily checks should focus on fluid levels, tire pressures, and visible signs of wear or damage. Weekly inspections can delve deeper, examining brake functionality and the condition of electrical systems. Monthly evaluations should include comprehensive assessments of safety equipment and structural integrity.

Documenting each inspection is crucial for tracking the vehicle’s condition over time. This practice not only ensures accountability but also serves as a reference for any future repairs or adjustments needed. Additionally, staying informed about industry standards and regulatory changes can help maintain compliance and avoid potential penalties.

Parts Replacement Best Practices

Ensuring optimal performance and longevity of heavy-duty vehicles relies heavily on effective component replacement strategies. Adhering to best practices during this process can significantly enhance operational efficiency and reduce the likelihood of future issues.

- Use Quality Components: Always opt for high-quality or OEM parts. This ensures compatibility and reliability.

- Follow Manufacturer Guidelines: Refer to official specifications and instructions when performing replacements to maintain vehicle integrity.

- Regular Inspections: Conduct frequent assessments to identify parts that may require replacement before they lead to failure.

- Proper Tools: Utilize the correct tools for each job to avoid damaging components and to ensure safe handling.

- Document Replacements: Keep a detailed log of all parts that have been replaced, including dates and specifics. This aids in future maintenance planning.

Implementing these best practices will contribute to smoother operations and extend the lifespan of the vehicle.

Resources for Further Learning

Enhancing your knowledge and skills in vehicle maintenance and troubleshooting can significantly improve your efficiency and confidence. A variety of resources are available to support your learning journey, from online courses to specialized literature, ensuring you have access to the most relevant and up-to-date information.

Online Platforms

- Video Tutorials: Websites like YouTube feature numerous channels dedicated to vehicle servicing, offering step-by-step guides and visual demonstrations.

- Online Courses: Platforms such as Udemy and Coursera provide comprehensive courses covering various aspects of vehicle mechanics and diagnostics.

- Forums and Communities: Engaging with online forums, like Reddit or specialized automotive forums, allows you to connect with other enthusiasts and professionals, sharing experiences and solutions.

Books and Publications

- Technical Manuals: Detailed publications provide in-depth insights into specific vehicle systems and maintenance procedures.

- Automotive Magazines: Subscribing to magazines focused on automotive technology keeps you informed about the latest trends and innovations in the industry.

- Workshops and Guides: Practical guides often include troubleshooting tips and best practices for various repair techniques.

Utilizing these resources will not only enhance your technical knowledge but also empower you to tackle challenges with greater assurance.